H+T type component and combination beam of H+T type component and floor

A technology of combining beams and components, applied in floors, building components, buildings, etc., can solve the problems of steel beam material waste, reduce indoor clearance, increase beam height, and improve flexural bearing capacity, flexural rigidity, and beam steel consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

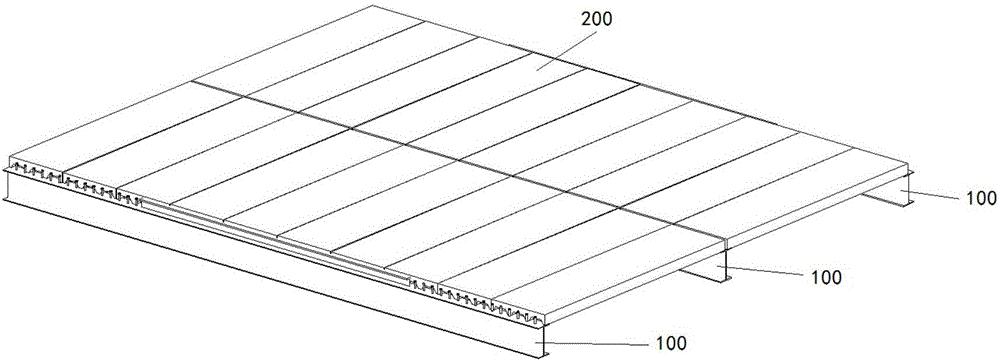

[0025] figure 1 It is a perspective view of the H+T-shaped component and the floor composite beam in the first embodiment.

[0026] Such as figure 1 As shown, the H+T-shaped component and floor composite beam includes: three H+T-shaped components 100 and a concrete floor assembly 200 .

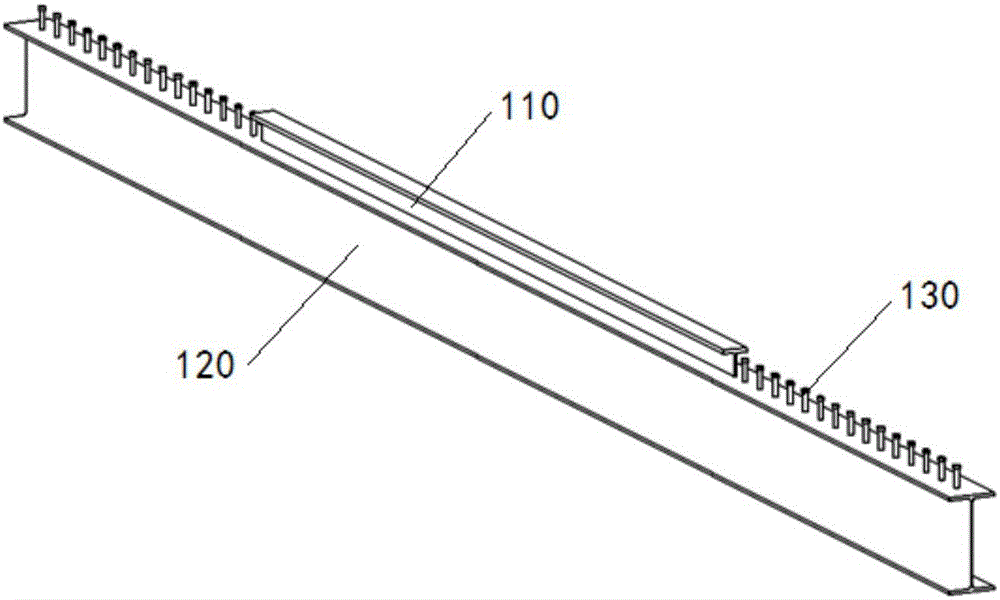

[0027] figure 2 It is a perspective view of the H+T-shaped component in Embodiment 1.

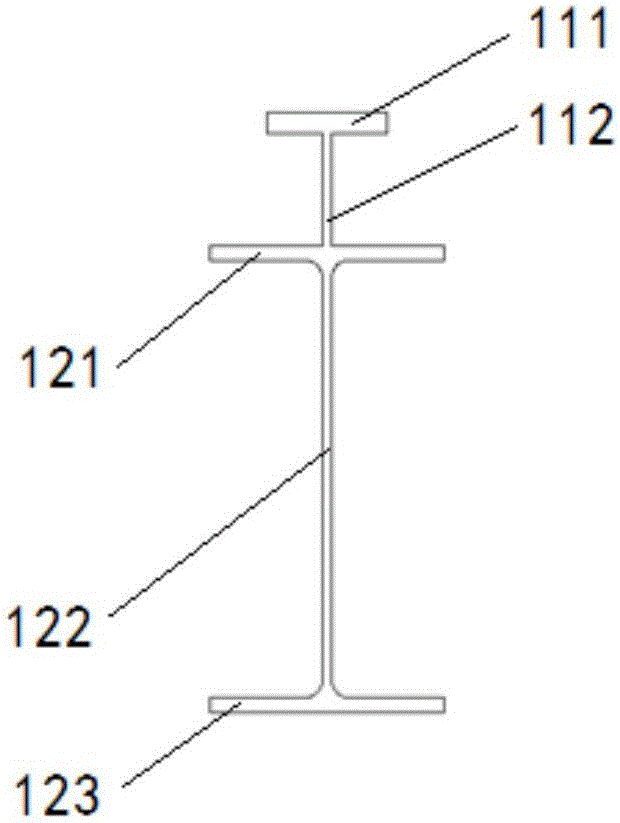

[0028] image 3 It is a cross-sectional view of an H+T-shaped component in Embodiment 1.

[0029] Such as figure 2 and image 3 As shown, the H+T-shaped component includes: a T-shaped bar 110 , an H-shaped bar 120 and several shear keys 130 .

[0030] The T-profile 110 comprises an upper flange 111 and a web 112 . The H-profile 120 includes an upper flange 121 , a web 122 and a lower flange 123 . The upper flange 111 of the T-shaped bar is parallel to the two flanges 121, 123 of the H-shaped bar, the web 112 of the T-shaped bar is in a straight line with the web 122 of the H-shaped bar, and the T...

Embodiment 2

[0039] Figure 5 It is a perspective view of the H+T-shaped component and the floor composite beam in the second embodiment.

[0040] Such as Figure 5 As shown, the H+T-shaped component and floor composite beam includes: three H+T-shaped components 100 and a concrete floor assembly 200 .

[0041] Figure 6 It is a perspective view of the H+T-shaped component in Embodiment 2.

[0042] Such as Figure 6 As shown, the T-shaped bar 110 of the H+T-shaped component 100 is long, and no shear key 130 is provided. The other parts are the same as those in the first embodiment, and will not be described again.

[0043] The H+T-shaped component and the floor composite beam in this embodiment are particularly suitable for use as a structural main beam.

[0044] The H+T components in Embodiment 1 and Embodiment 2 can be used in any combination with the concrete floor assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com