Rail plate

A track slab and slab body technology, applied in the field of track slabs, can solve the problems of track slabs such as poor bending and tensile capacity and easy cracking, so as to ensure the tensile and bending capacity, improve the bending and tensile capacity, and reduce the use of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

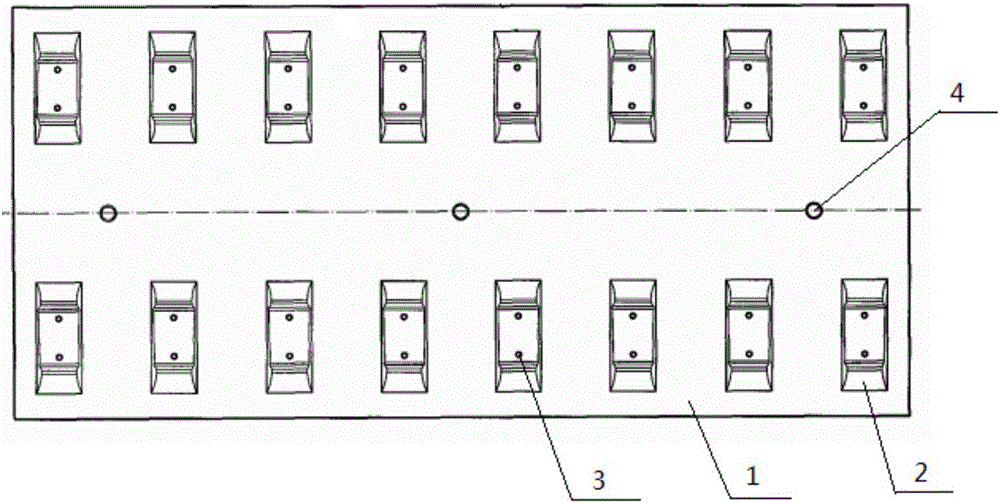

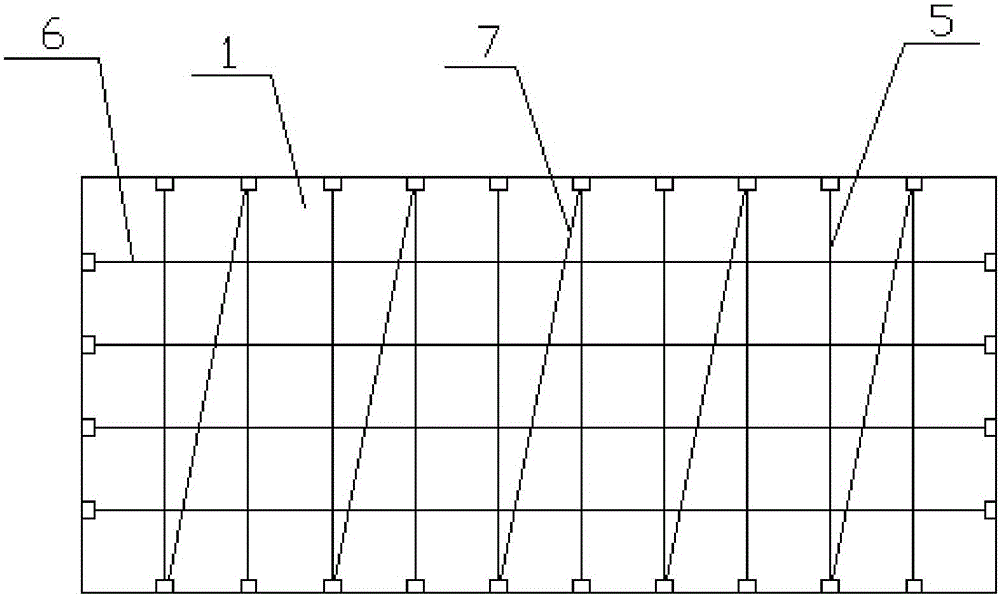

[0026] Such as figure 1 , figure 2 As shown, a track slab includes a track slab body 1, the slab body 1 is a concrete prefabricated part, a rail support platform 2 arranged on the slab body 1, and an insulating pre-embedded casing 3 embedded in the rail support platform 2 , several grouting holes 4 arranged on the central axis of the plate body 1, a plurality of transverse prestressed reinforcement bars 5 and a plurality of longitudinal prestressed reinforcement bars 6 fixed inside the plate body 1; A plurality of oblique prestressed reinforcement bars 7 parallel to each other, the two ends of the oblique prestressed reinforcement bars 7 are respectively connected to the ends of two adjacent transverse prestressed reinforcement bars 5 located on the two opposite sides of the plate body 1, and the oblique prestressed reinforcement bars Stress bars 7 are arranged at intervals between adjacent transverse prestress bars 5, that is, oblique prestress bars 7 are arranged between t...

Embodiment 2

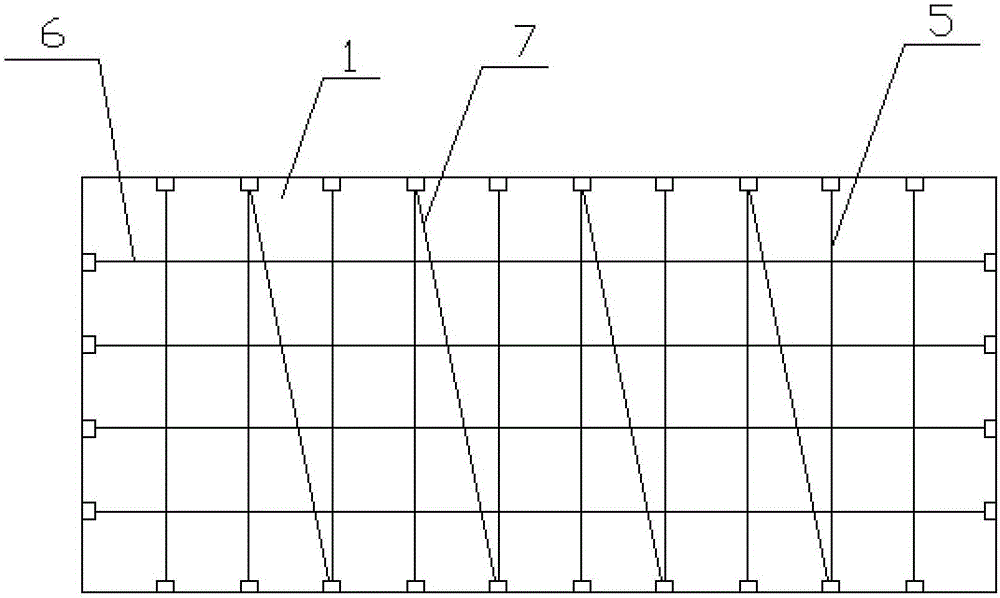

[0028] Different from Example 1, as image 3 , Figure 4 , Figure 5 As shown, the transverse prestressed reinforcement 5, the longitudinal prestressed reinforcement 6 and the oblique prestressed reinforcement 7 are arranged in two layers. staggered arrangement, that is, there is no oblique prestressed reinforcement 7 between adjacent transverse prestressed reinforcements 5 on the upper layer, and the corresponding position of the lower layer is provided with an oblique direction opposite to that of the oblique prestressed reinforcement 7 on the upper layer. To the prestressed reinforcement 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com