Secondary vacuum coating equipment for thickening metalized thin film

A technology of metallized film and secondary vacuum, which is applied in the field of coating machine, can solve the problems affecting the normal transmission of the film, floating, shape invariability, etc., and achieve the effect of adjustable coating thickness, preventing floating and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further describe the present invention, it is further described below in conjunction with embodiment.

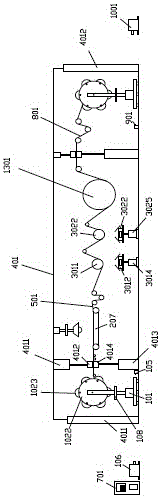

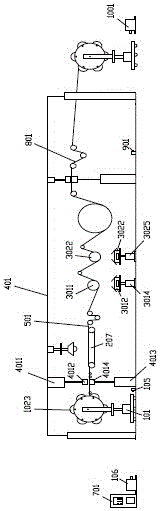

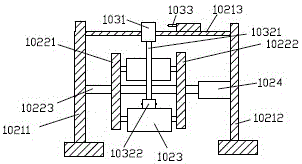

[0043] Such as figure 1As shown, the present invention discloses a secondary vacuum coating machine for metallized film thickening, including a vacuum chamber 401 and a feeding mechanism, a coating mechanism, and a winding mechanism arranged in the vacuum chamber 401 . The feeding mechanism, the coating mechanism, and the winding mechanism are arranged in sequence from front to back according to the process flow.

[0044] Such as figure 1 As shown, the feeding mechanism includes a first lifting mechanism 101 and a feeding device. The telescopic end of the first lifting mechanism 101 cooperates with the feeding device to drive the feeding device to move up and down.

[0045] Such as figure 1 As shown, the vacuum chamber 401 includes a chamber entrance door 4011 at the entrance end and a chamber exit door 4012 at the exit end.

[0046] Such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com