Weather-resistant, bending-resistant, high-gloss and low-light-transmittance ABS material and preparation method thereof

An ABS material, anti-bending technology, applied in the polymer field, can solve the problems affecting the qualification rate and use of light-shielding ABS material injection products, poor long-term weather resistance, poor processing fluidity, etc., and achieve excellent long-term weather resistance and high gloss. , the effect of high notched impact strength

Inactive Publication Date: 2017-02-15

GUANGDONG WAYLAM ENG PLASTICS

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the shading ABS resin produced by this invention patent has good shading effect and high gloss, it has poor processing fluidity, high production cost, poor long-term weather resistance, and added barium sulfate or t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

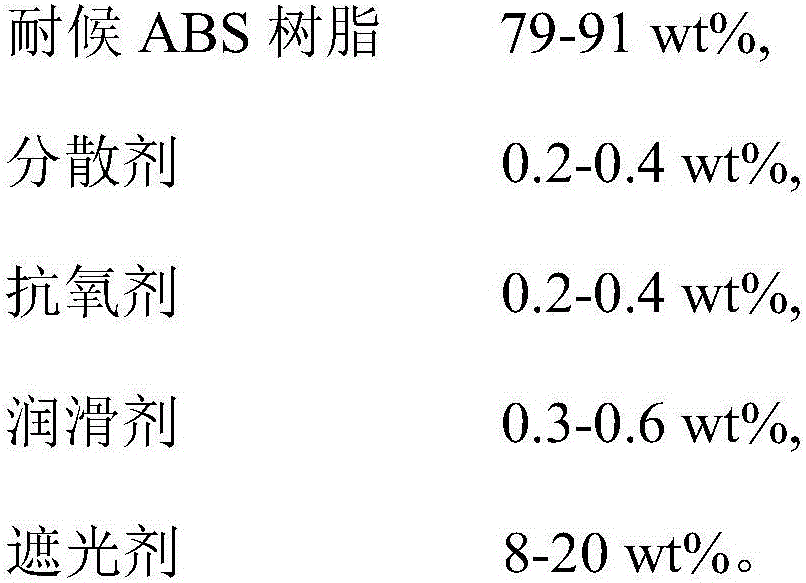

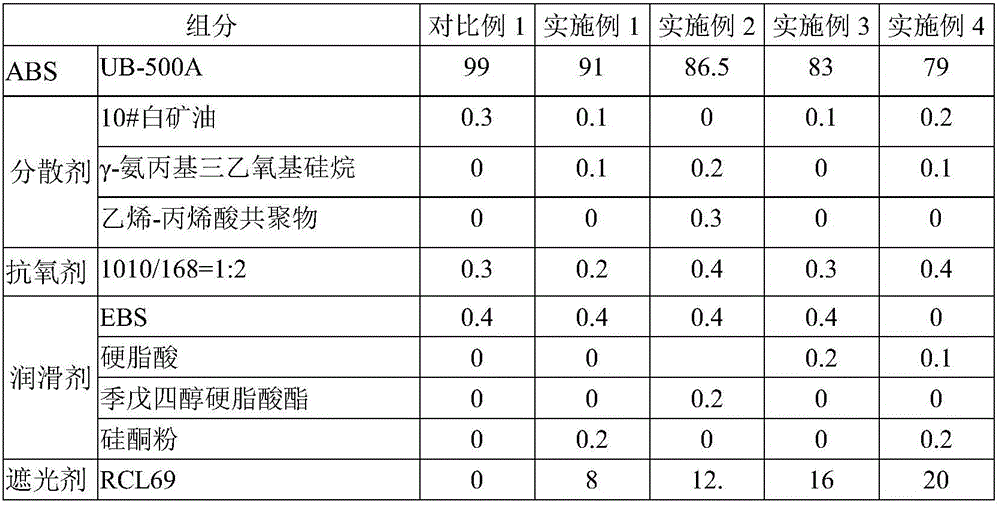

The invention discloses a weather-resistant, bending-resistant, high-gloss and low-light-transmittance ABS (Acrylonitrile Butadiene Styrene) material. The key point of the technical scheme is that the weather-resistant, bending-resistant, high-gloss and low-light-transmittance ABS material contains the following components in percentage by mass: 79-91wt% of weather-resistant ABS resin, 0.2-0.4wt% of a dispersant, 0.2-0.4wt% of an antioxidant, 0.3-0.6wt% of a lubricant, and 8-20wt% of a light-screening agent. The weather-resistant, bending-resistant, high-gloss and low-light-transmittance ABS material provided by the invention is relatively good in shading effect, better in weather resistance and fluidity and lower in cost.

Description

[0001] 【Technical field】 [0002] The invention belongs to the technical field of macromolecules, and in particular relates to an ABS material with weather resistance, bending resistance, high gloss and low light transmittance and a preparation method thereof. [0003] 【Background technique】 [0004] Acrylonitrile-butadiene-styrene copolymer is a terpolymer composed of acrylonitrile, butadiene and styrene, referred to as ABS. ABS has good chemical resistance, high notched impact strength, good processing fluidity, excellent gloss, excellent coloring and good electroplating performance, but it is exposed to ultraviolet light for a long time due to its double bond Yellows and becomes brittle when exposed to light. To improve the weather resistance of ABS resin, a relatively simple method is to add antioxidants, ultraviolet absorbers and light stabilizers to ABS resin, but the weather-resistant ABS produced by this method only has a short-term weather resistance effect, and it wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L55/02C08L91/06C08L23/08C08K13/02C08K3/22B29C47/92B29C48/92

CPCC08L55/02B29C48/92B29C2948/9258B29C2948/92704C08L2205/03C08L91/06C08K13/02C08K2003/2241C08L23/0869

Inventor 胡勤皮正亮葛嘉宝

Owner GUANGDONG WAYLAM ENG PLASTICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com