A motor packaging line

A packaging line and paper cutter technology, applied in the field of packaging, can solve the problems of inability to guarantee product packaging quality, high pressure on enterprise warehouses, and prolong production cycle, achieving the effects of simple structure, reduced labor costs, and reduced plant area occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

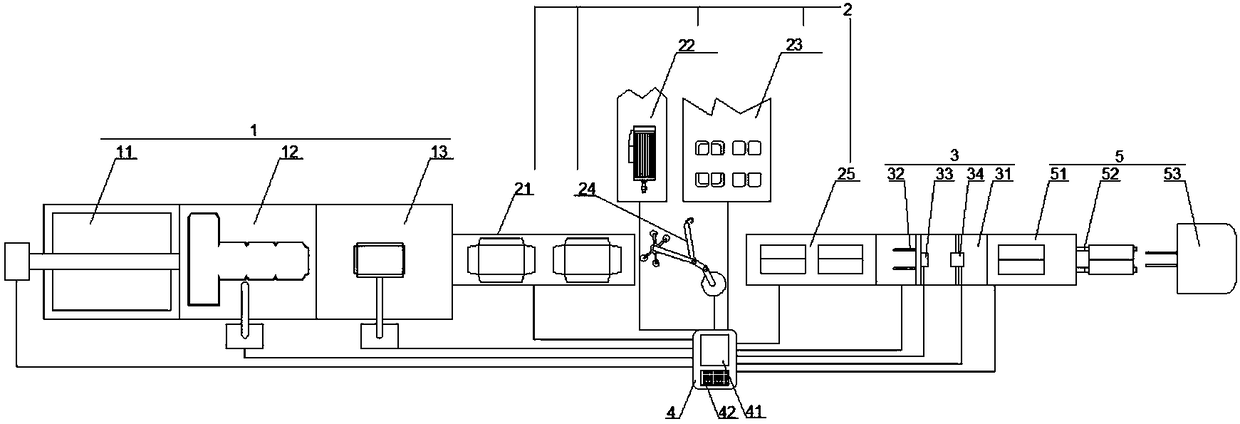

[0021] as follows figure 1 As shown, the motor packaging line includes an unpacking mechanism, a filling mechanism, a packaging mechanism, and a controller; the discharge port of the unpacking mechanism is connected to a feed port of the filling mechanism; the discharge port of the filling mechanism is connected to the feed port of the packing mechanism connected; the discharge port of the packaging mechanism is connected with the feed port of the stacking mechanism; the controller is electrically connected with the unpacking mechanism and the packing mechanism respectively. The entire packaging line shows the unpacking, filling and packaging process, which is fully automated and improves production efficiency.

[0022] The unpacking mechanism includes a cardboard conveying unit, a paper cutter, and a folding box unit; the cardboard conveying unit is installed on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com