An automatic stamping machine

A technology of automatic stamping machine and swing rod, applied in printing, stamping and other directions, can solve the problems of laboriousness, certain requirements for paper size and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0013] The invention provides an automatic stamping machine. After the stamping position is determined, through the combination of mechanical movement and control principle, the stamping gap is just running paper, and the next stamping action is performed after the paper is traveled, thereby realizing automatic stamping.

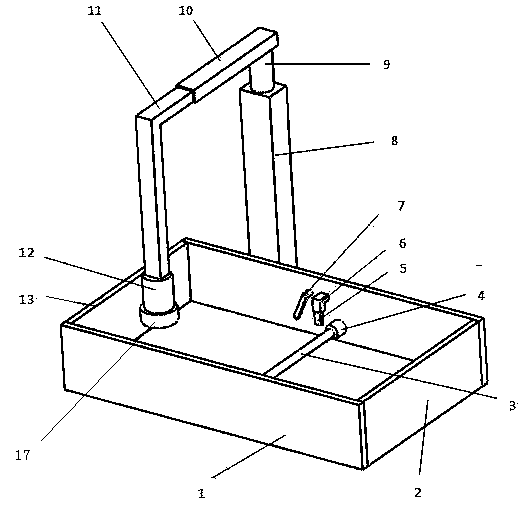

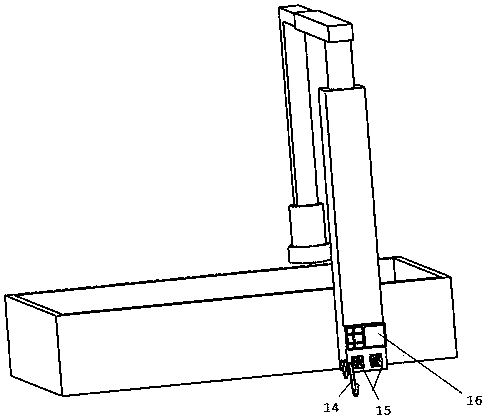

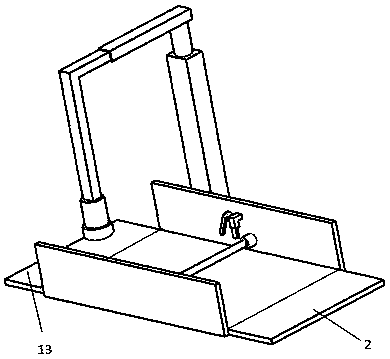

[0014] As an embodiment of the present invention, the present invention provides an automatic stamping machine, including a paper placement slot 1, a roller shaft 3, a roller 4, a paper sucking rod telescopic rod 5, a paper sucking rod fixing rod 6, and a paper swinging rod 7. , The vertical rod 8, the rotating shaft 9, the cross rod 10, the horizontal telescopic rod 11, the longitudinal telescopic rod 12, the power cord 14 and the chapter 17. There is a roller shaft 3 in the paper placing slot 1, and the two ends of the roller shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com