Induction brazing equipment and method

A technology of induction brazing equipment and induction heating, applied in welding equipment, metal processing equipment, electric heating devices, etc., can solve the problems of poor operating environment, low efficiency, poor coordination of components, etc., to broaden flexibility and reduce adjustment difficulty , the effect of shortening the adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described below, and it should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

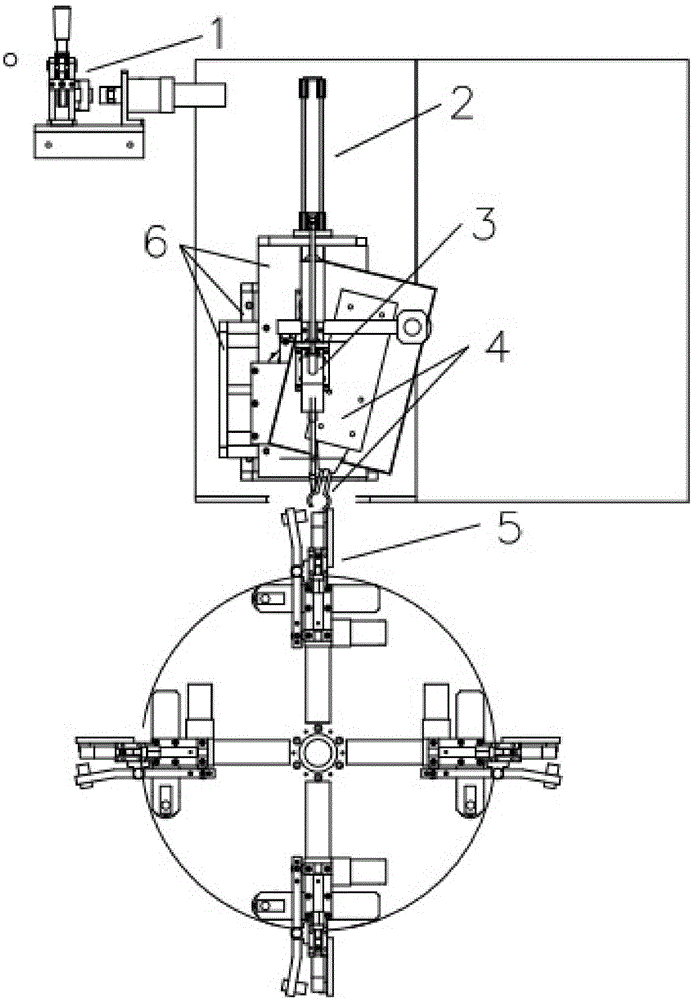

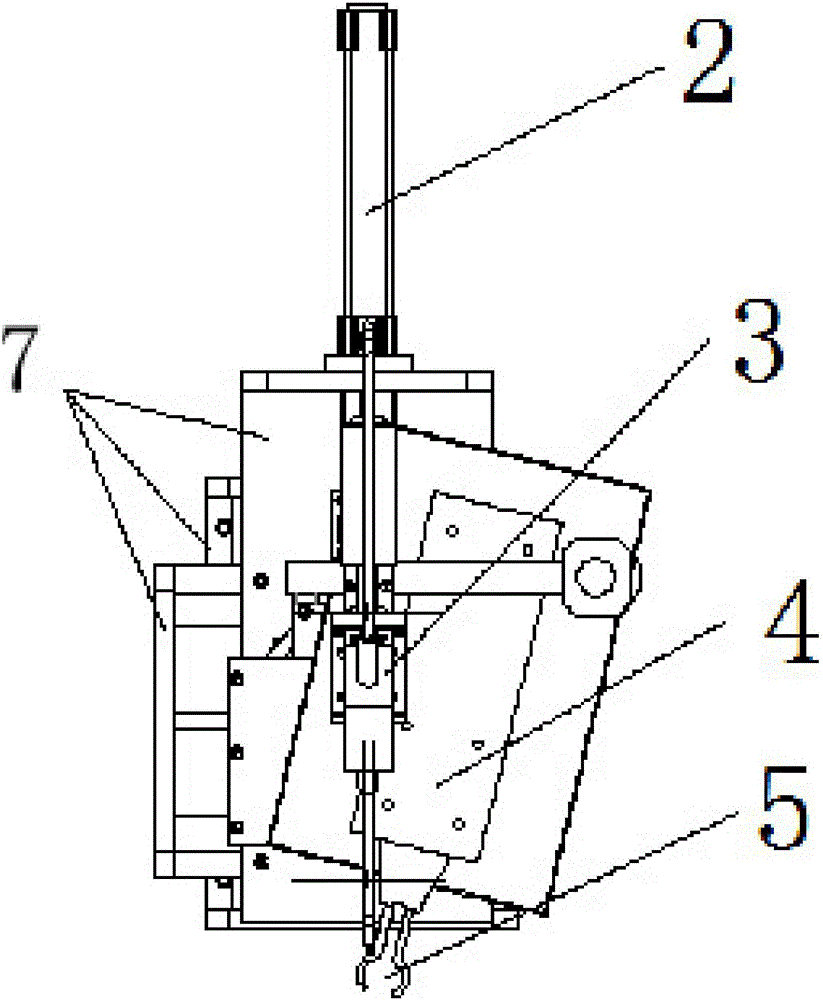

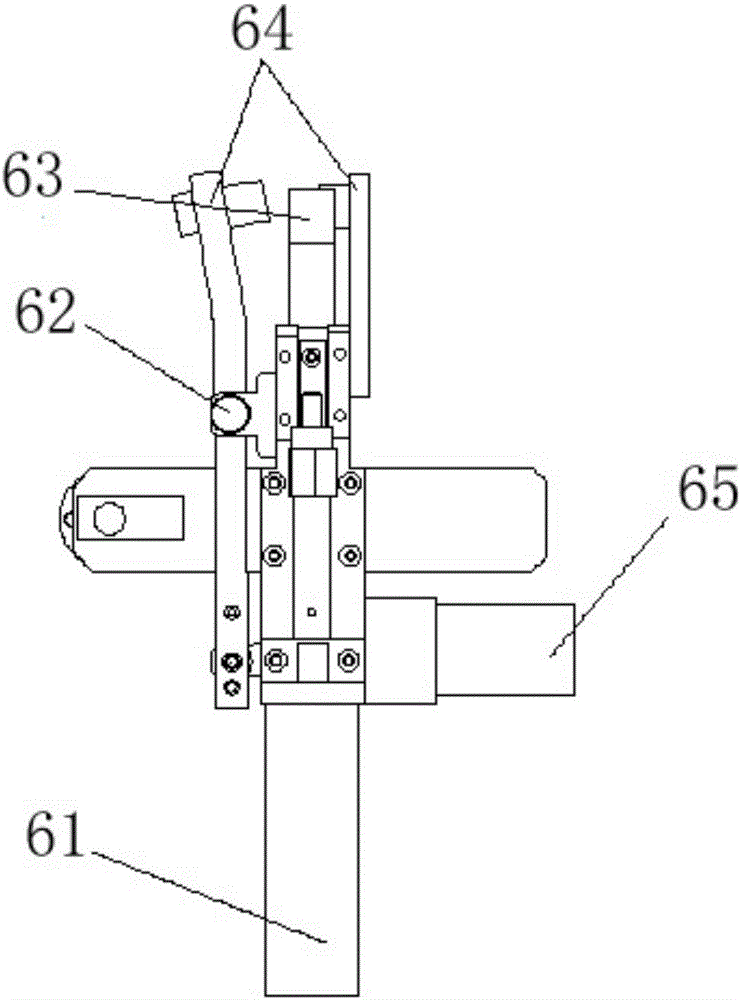

[0043] Embodiments of the present invention provide an induction brazing device, such as figure 1 As shown, it includes a positioning tool 6, a welding device, a detector and a frame. A detector (eg, an infrared probe) is used to detect whether the welding workpiece is located at a predetermined position, that is, whether a welding workpiece 8, such as a welded pipe, is clamped when the positioning tool 6 is in the welding station. The detector is installed at the previous station adjacent to the welding station on the frame, which is convenient for adjustment and avoids interference in the welding station.

[0044] The welding device is used to weld the welding workpiece when the detector detects that the welding wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com