Nozzle water cooling centre pneumatic device

A pneumatic device and thimble technology, applied in the field of sand casting, can solve the problems of poor fluidity of wet inorganic sand and inability to shoot sand, so as to achieve smooth sand shooting and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

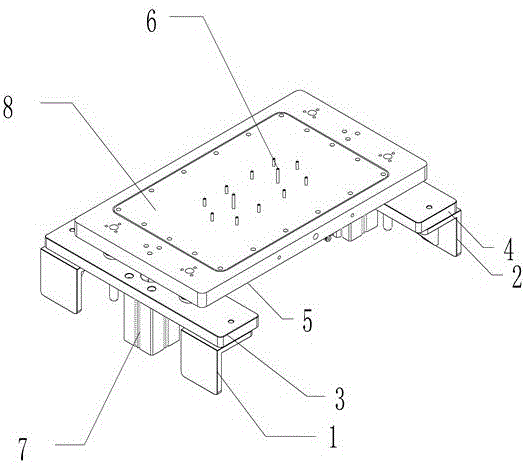

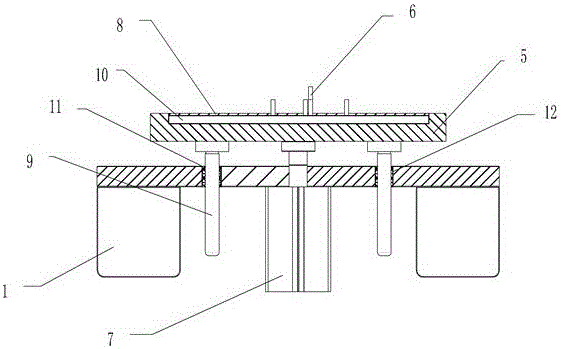

[0020] The reference signs in the accompanying drawings of the specification include: left support seat 1, right support seat 2, left beam plate 3, right beam plate 4, water-cooled base plate 5, double-layer thimble 6, cylinder 7, replaceable thimble plate 8, guide post 9. Water chamber 10, guide post hole 11, guide post cover 12.

[0021] The embodiment is basically as attached figure 1 with figure 2 Shown:

[0022] The nozzle water-cooled thimble pneumatic device in this solution includes a left support seat 1 and a right support seat 2, the upper surface of the left support seat 1 is connected with a left beam plate 3, and the left beam plate 3 is provided with two through guide post holes 11 , the upper surface of the right support seat 2 is connected with the right beam plate 4, and the right beam plate 4 is also provided with two through guide post holes 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com