Preparation method of composite material of mesoporous carbon-silica loaded nano-moo3 and nano-metal particles

A technology of nano metal particles and composite materials, applied in the field of inorganic nano material preparation, can solve the problems of slow hydrogen transfer catalysis rate of aryl nitro compounds, unconcentrated pore size distribution, complicated preparation process, etc., and achieves high activity and selectivity, operation Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

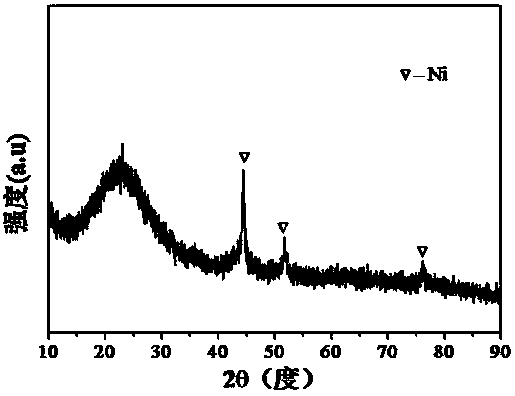

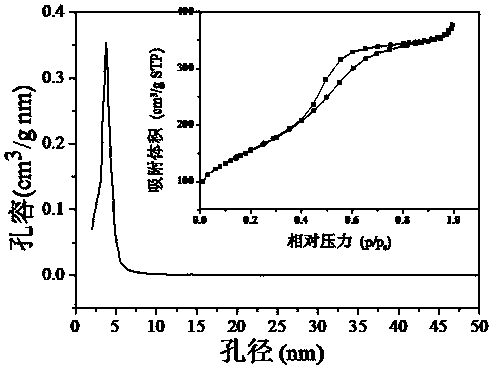

[0028] In this example, see Figure 1~3 , a mesoporous carbon-silica supported nano-MoO 3 The preparation method of the composite material with nano metal particles is characterized in that it comprises the following steps:

[0029] a. Using the mixed solution of ethanol and water as solvent, dissolve 0.3g nickel nitrate hexahydrate, 0.0334g ammonium molybdate tetrahydrate and 1g SBA-15 in 40ml water / ethanol (v / v=1:1) mixed solution , ultrasonically oscillating at room temperature for 30 minutes until SBA-15 is completely dispersed in the solution to obtain the first mixed solution;

[0030] b. Constantly stirring the first mixed solution prepared in the step a at 40°C, gradually evaporating the solvent to obtain a solid, and heating at 400°C for 2 h in an air atmosphere to obtain the first solid material;

[0031]c. Using a mixed solution of ethanol and water as a solvent, dissolve 0.5 g of the first solid material obtained in step b into 40 ml of a mixed solution of water ...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, especially in that:

[0040] In this example, see Figure 4~6 , a mesoporous carbon-silica supported nano-MoO 3 The preparation method of the composite material with nano metal particles is characterized in that it comprises the following steps:

[0041] a. Using a mixed solution of ethanol and water as a solvent, dissolve 0.3g of cobalt nitrate hexahydrate, 0.0334g of ammonium molybdate tetrahydrate and 1g of SBA-15 in 40ml of water / ethanol (v / v=1:1) mixed solution , ultrasonically oscillating at room temperature for 30 minutes until SBA-15 is completely dispersed in the solution to obtain the first mixed solution;

[0042] b. Constantly stirring the first mixed solution prepared in step a at 60° C., gradually evaporating the solvent to obtain a solid, and heating at 400° C. for 2 h in an air atmosphere to obtain the first solid material;

[0043] c. Dissolve 0.5 g of the first solid material obtained in the ste...

Embodiment 3

[0049] This embodiment is basically the same as the previous embodiment, and the special features are:

[0050] In this example, see Figure 7-9 , a mesoporous carbon-silica supported nano-MoO 3 The preparation method of the composite material with nano metal particles is characterized in that it comprises the following steps:

[0051] a. Using a mixed solution of ethanol and water as a solvent, dissolve 0.25g of ferric nitrate hexahydrate, 0.0334g of ammonium molybdate tetrahydrate and 1g of SBA-15 in 40ml of water / ethanol (v / v=1:1) mixed solution , ultrasonically oscillating at room temperature for 30 minutes until SBA-15 is completely dispersed in the solution to obtain the first mixed solution;

[0052] b. Constantly stirring the first mixed solution prepared in the step a at 50°C, gradually evaporating the solvent to obtain a solid, and heating at 400°C for 2 h in an air atmosphere to obtain the first solid material;

[0053] c. Dissolve 0.5g of the first solid materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com