Sugarcane harvester conveying arm rotation joint

A technology of rotating joints and conveying arms, which is applied to harvesters, agricultural machinery and implements, and applications, and can solve the problems of low mechanization, high sugar production costs, and lack of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

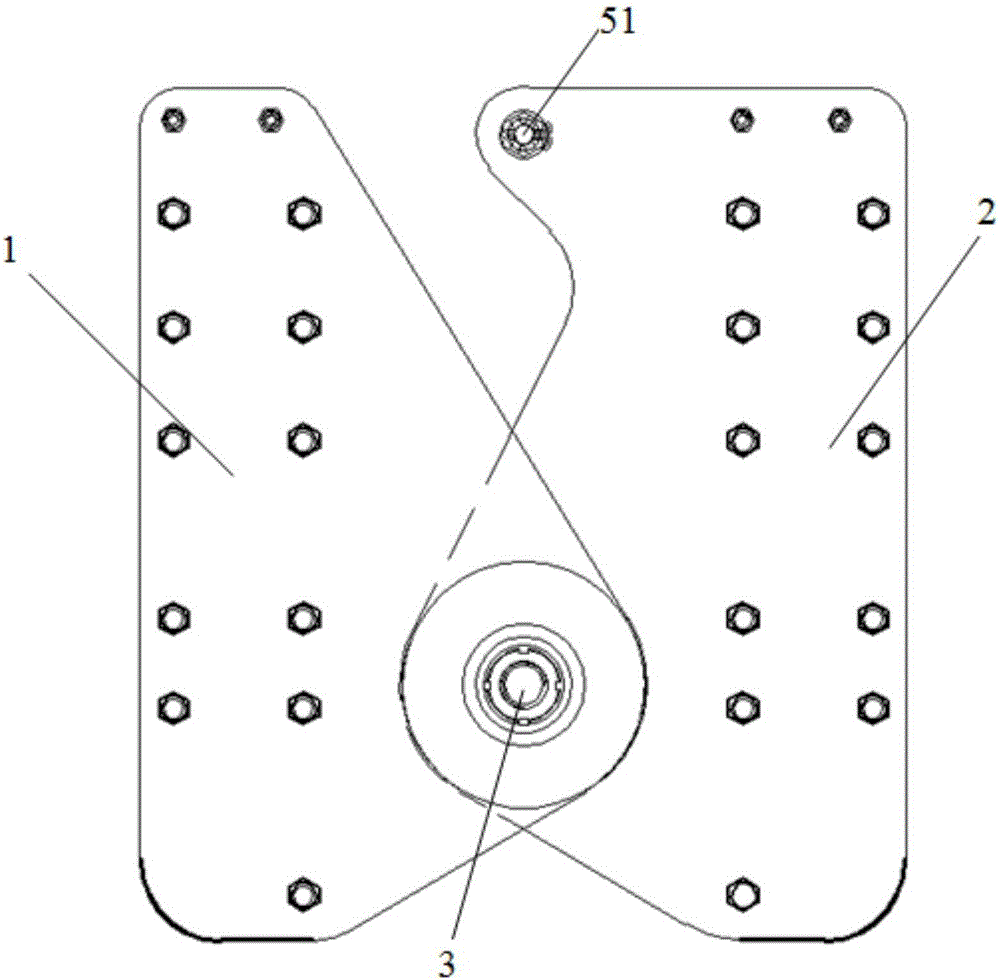

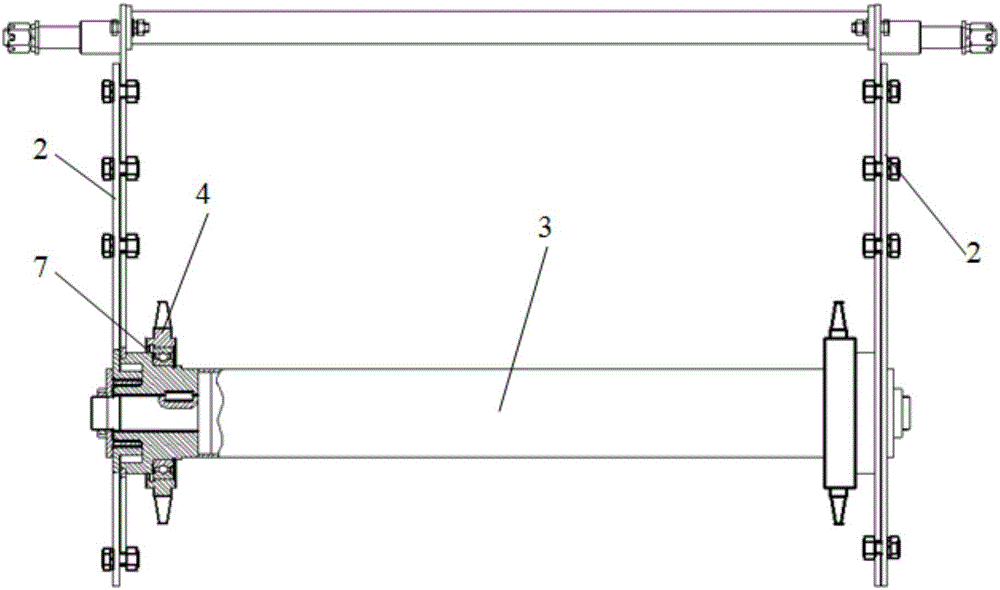

[0011] to combine figure 1 , figure 2 , which describes the specific implementation of the present invention in detail, but does not limit the claims in any way.

[0012] Such as figure 1 , figure 2 As shown, a sugarcane harvester conveying arm rotating joint includes a front baffle 1, a joint plate 2, a transition wheel shaft 3, a transition wheel 4, a hydraulic cylinder, a bottom plate of the conveying arm, and a deep groove bearing 7. The front baffle 1 passes through the transition wheel shaft 3. It is hingedly connected with the joint plate 2. The joint plate 2 can rotate around the transition wheel shaft 3. The front baffle plate 1 and the joint plate 2 are two pieces respectively, which are respectively connected with the left and right ends of the transition wheel shaft 3 by the above connection method. The mounting hole on the left side of plate 1 and the mounting hole on the right side of joint plate 2 are respectively connected to the lower section of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com