A method for preparing cellulose nano-whiskers from microcrystalline cellulose in combination with alkali treatment and high-intensity ultrasound

A technology of microcrystalline cellulose and nano-whiskers, which is applied in the field of nano-material preparation, can solve the problems of high acid consumption of cellulose nano-whiskers, secondary pollution, sulfonic acid groups reduce the thermal stability of cellulose nano-whiskers, etc. , to achieve the effect of low cost, easy operation and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Soaking: add microcrystalline cellulose to water and soak for 12-24 hours to obtain water-soaked microcrystalline cellulose.

[0040] 2) Alkali treatment:

[0041] According to the mass ratio of 1:10~30, add the soaked microcrystalline cellulose into the aqueous sodium hydroxide solution, keep the temperature at 70°C, and react for 1~2h at the stirring speed of 200~2000rpm (rev / min) to obtain alkali-treated microcrystalline cellulose. Crystalline cellulose, the concentration of sodium hydroxide aqueous solution is 3% to 5%.

[0042] 3) Acid treatment:

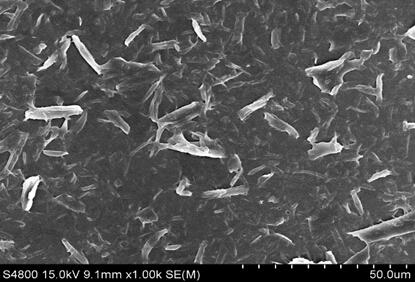

[0043] According to the mass ratio of 1:10-30, add the alkali-treated microcrystalline cellulose to the hydrochloric acid aqueous solution, keep the temperature at 90°C, and react for 1-4 hours under the condition of stirring speed of 200-2000rpm to obtain the acid-treated microcrystalline cellulose, the concentration of the hydrochloric acid aqueous solution 1% to 2%. The SEM photo of microcrystalline cellulose af...

Embodiment 2

[0049] The difference between this embodiment and the first embodiment is:

[0050] In step 2), the reaction temperature is 80°C, and the concentration of the aqueous sodium hydroxide solution is 5% to 7%;

[0051] In step 3), the reaction temperature is 85°C, and the concentration of the aqueous hydrochloric acid solution is 2% to 4%;

[0052] In step 4), the output power of the ultrasound is 1000-1200W, and the ultrasound time is 25-35 minutes.

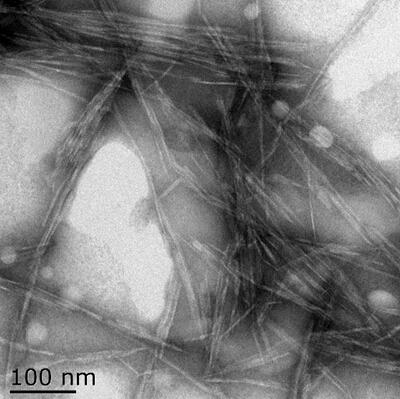

[0053] The TEM picture of gained cellulose nano whiskers is shown in Figure II .

Embodiment 3

[0055] The difference between this embodiment and the specific embodiment one and two is:

[0056] In step 2), the reaction temperature is 90°C, and the concentration of the aqueous sodium hydroxide solution is 7% to 9%;

[0057] In step 3), the reaction temperature is 80°C, and the concentration of the aqueous hydrochloric acid solution is 4% to 6%;

[0058] In step 4), the output power of the ultrasound is 1200-1500W, and the ultrasound time is 20-30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com