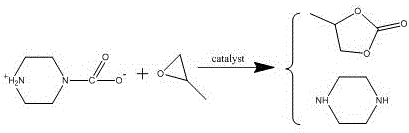

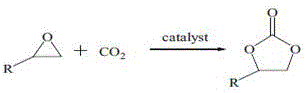

Preparation method of ethylene carbonate (propylene carbonate)

A technology of alkenyl ester and carbonic acid, applied in the direction of organic chemistry, can solve the problems of difficult wide application, environmental pollution, restrictions, etc., and achieve the effect of improving catalytic activity, high catalytic activity, and easy synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] (1) Preparation of carbamate: under normal temperature and pressure, configure the mixed solution of alkylpolyamine / organic solvent in a 250ml three-necked flask, CO 2 The gas mass flow controller was used to control the flow into the three-necked flask, and reacted for 2 h; the obtained liquid-solid mixture was separated under reduced pressure to obtain a solid, which was placed in a vacuum drying oven at 40 ° C for 1 h, and stored for later use; the absorbent alkyl The polyamine is one of ethylenediamine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine, and piperazine, and the organic solvent is ethanol, diethylene glycol dimethyl ether, N-methylpyrrolidone, and propylene carbonate One of the esters.

[0024] (2) Preparation of ethylene (propylene) carbonate without a catalyst: add a certain amount of the above five carbamates, EO, and PO into a 50ml hydrothermal reaction crystallization kettle, and use collector type constant temperature heating and ...

Embodiment 1

[0027] It is 6:1 to mix and join in the 50ml hydrothermal reaction crystallization kettle by the mol ratio of EO and ethylenediamine-carbamate, add catalyst ZnO 0.1%mol (promptly account for the mol percentage of total system), adopt heat-collecting type The treatment temperature was controlled by a constant temperature heating magnetic stirrer at 100 °C, the reaction time was 0.5 h, and naturally cooled to room temperature after the reaction; the yield of EC was 92.6%, and the yield of ethylenediamine was 95.2%.

Embodiment 2

[0029] According to the molar ratio of PO and ethylenediamine-carbamate is 6:1 mixed into the 50ml hydrothermal reaction crystallization kettle, add catalyst KF 0.5% mol (that is, account for the mole percentage of the total system), adopt the heat collection method The treatment temperature was controlled by a constant temperature heating magnetic stirrer at 100 °C, the reaction time was 0.5 h, and naturally cooled to room temperature after the reaction; the yield of PC was 90.2%, and the yield of ethylenediamine was 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com