Sewage oxygen charging system and oxygen charging method

A water distribution system and sewage technology, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems of limited use, high construction cost, and high protection height of the surface aeration tank, so as to prevent short flow and energy consumption Low, easy access and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

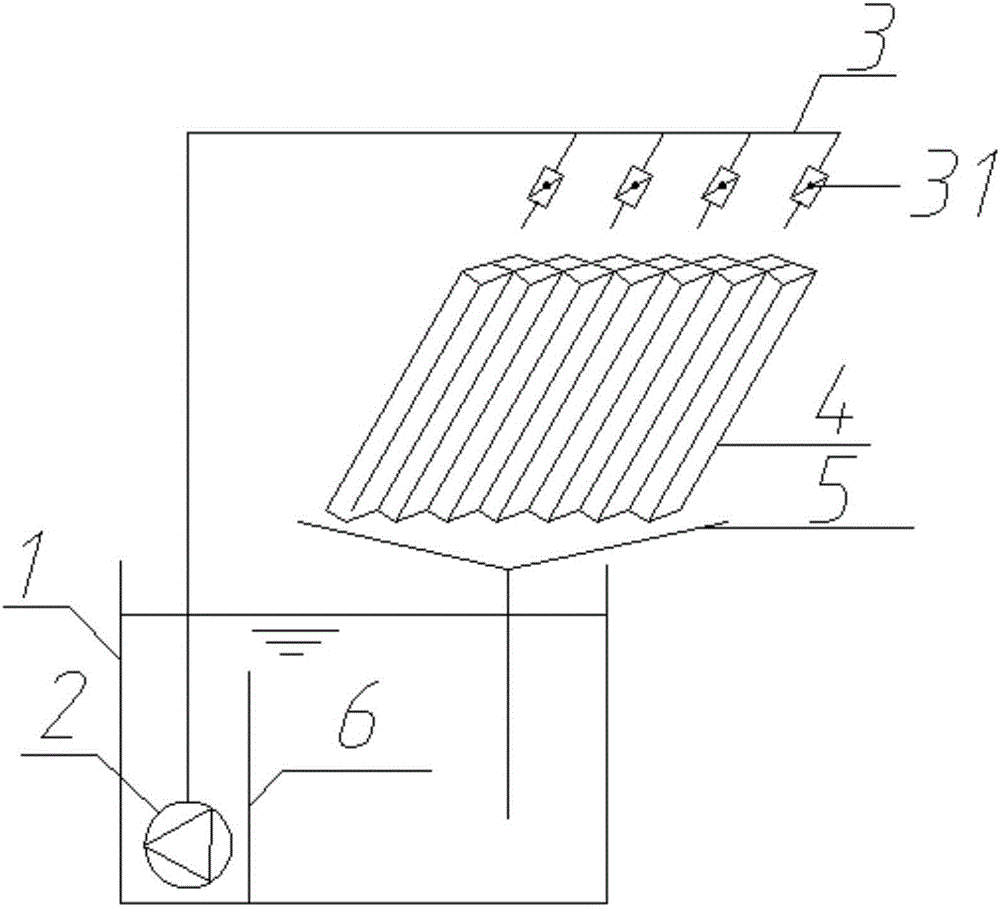

[0068] Such as figure 1 As shown, this embodiment provides a sewage oxygenation system, including: an aerobic pool 1, a sewage circulation device 2, a water distribution system 3, an oxygenation filler 4, a backflow device 5 and a partition 6;

[0069] The separator 6 divides the aerobic pool 1 into a circulation area and an oxygenation area. The sewage circulation device 2 is located in the circulation area, and the backflow device 5 extends into the oxygenation area; Oxygen filling 4; the oxygen filling 4 is located above the aerobic pool 1, and the backflow device 5 is located below the oxygen filling 4.

[0070] The water distribution system 3 in the present invention includes a water distribution pipeline and a valve 31, and the valve 31 is mainly used to control the flow of water distribution. The water distribution system 3 also includes a spraying device, which can be a spray head arranged at the end of the water distribution pipeline or a through hole uniformly arran...

Embodiment 2

[0083] Embodiment 2: comparative example

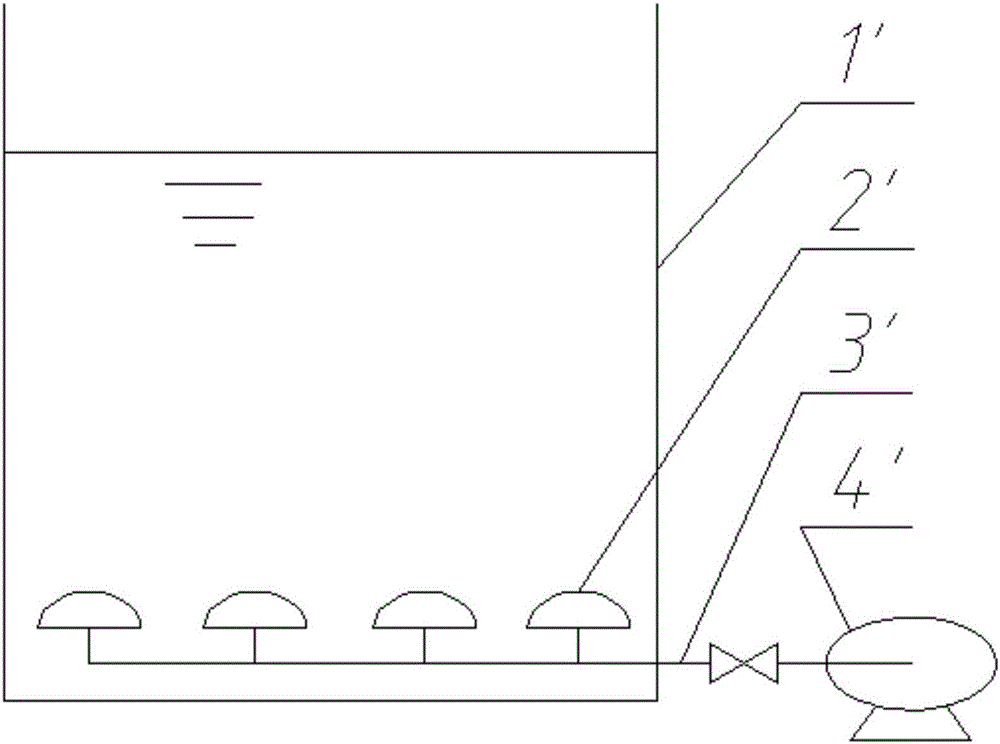

[0084] Such as figure 2 As shown, the present embodiment provides a traditional blast aeration and oxygenation system, comprising: an aerobic tank 1', an aeration head 2'; an aeration pipeline system 3'; and a blower 4'.

[0085] The traditional blower aeration and oxygenation system uses the blower 4' to pump air into the aeration pipeline system 3' located at the bottom of the aerobic tank 1', and then aerates the air to the aerobic tank 1 through the aeration head 2' 'In the sewage, realize the oxygenation of sewage.

[0086] In this embodiment, the head of the air blower 4' is relatively large, which is generally the water depth plus the resistance of the aeration pipeline system, while the depth of the traditional aerobic tank 1' is generally 4-5 meters, so the wind pressure required by the air blower 4' It is a head of 5-7 meters. After the air bubbles (air) enter the bottom of the pool, they rise rapidly, the residence time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com