An automatic off-line device for automobile body welding assembly

A technology for automatic off-line and automobile body, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of weak data processing ability, closed architecture, poor compatibility, etc., to promote the development of information technology and improve the control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

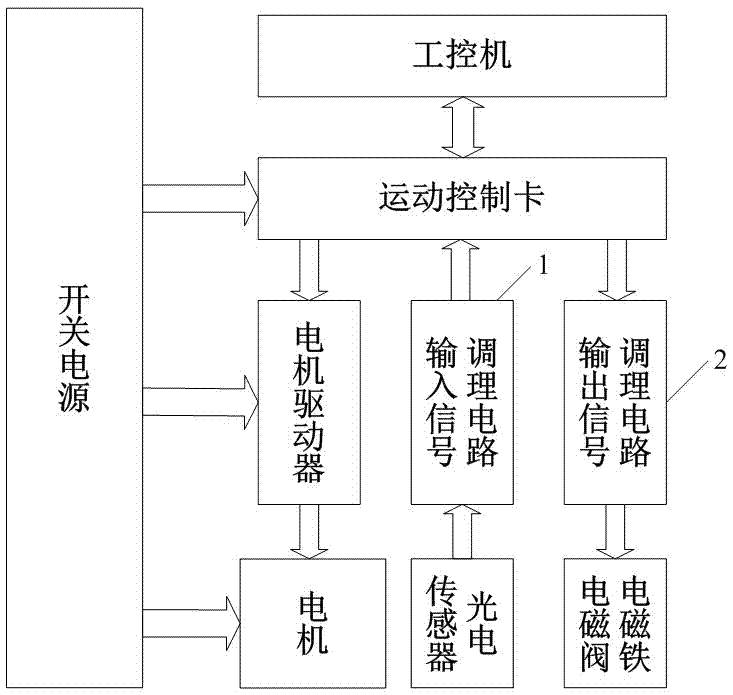

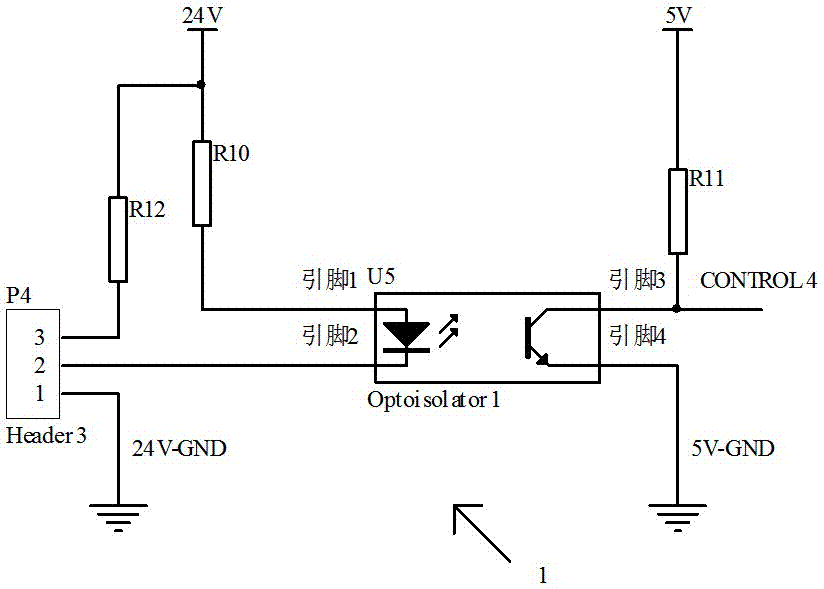

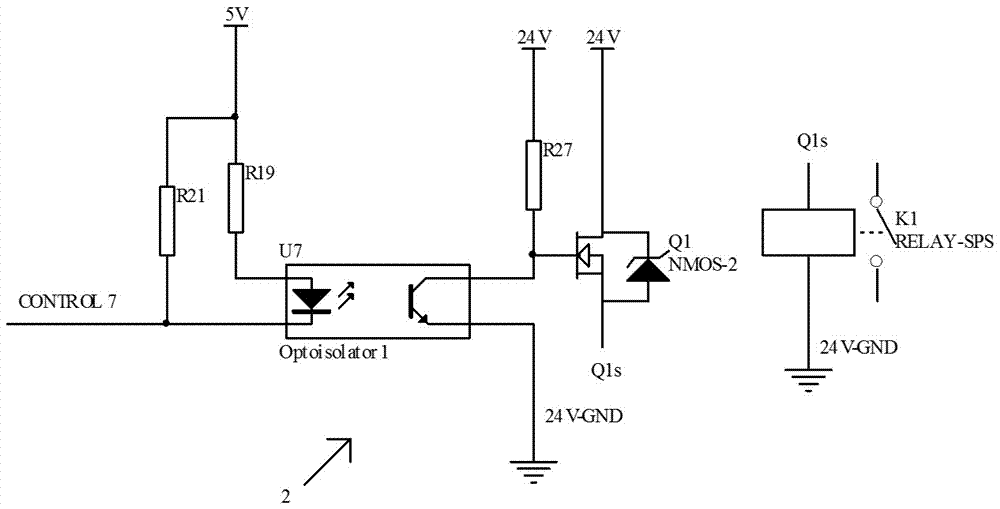

[0016] Such as figure 1 As shown, an automatic off-line device for automobile body welding assembly includes an industrial computer, and the industrial computer communicates with the motion control card in two directions. The output ends of the motion control card are respectively connected to the input ends of the motor driver and the output signal conditioning circuit 2 The output terminal of the motor driver is connected with the input terminal of the motor, the output terminal of the output signal conditioning circuit 2 is connected with the electromagnet or solenoid valve, the input terminal of the motion control card is connected with the output terminal of the input signal conditioning circuit 1, and the input signal conditioning circuit The input terminal of the circuit 1 is connected with the output terminal of the photoelectric sensor, and the switching power supply supplies power to the motion control card, the motor driver, the motor, the input signal conditioning c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com