Automatic hole digger for planting seedlings

A kind of digging machine, automatic technology, applied in the direction of planting method, application, digging/covering trenches, etc., can solve the problems of tree transplanting death, tree overturning, time-consuming, etc., to shorten planting time, improve efficiency, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0024] One of the preferred embodiments of the present invention is described and set forth in detail below:

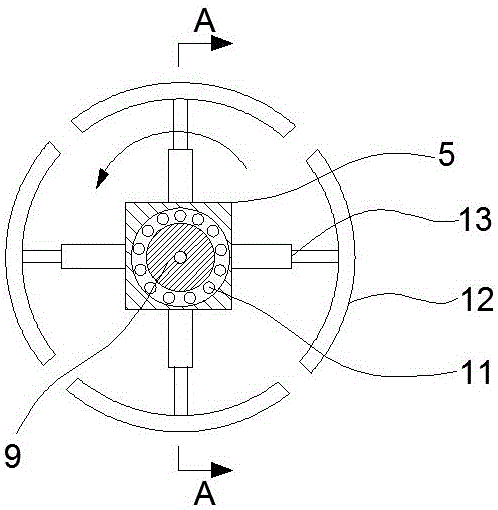

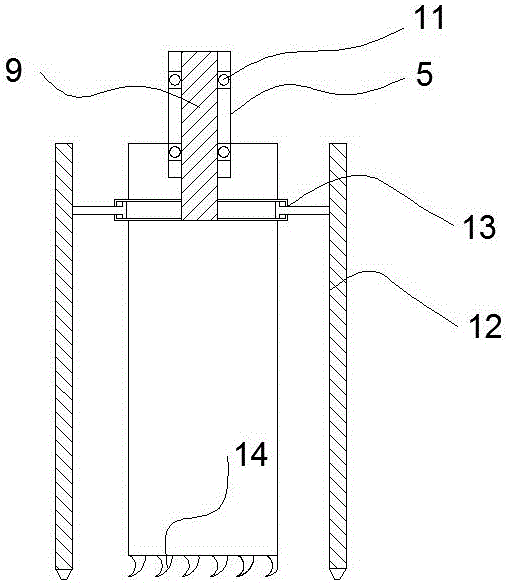

[0025] combined with Figure 1-4 Shown, a kind of automatic digging machine that is used for nursery stock planting, comprises car body, wheel, digging device, is used to control the hydraulic system of described digging device, and described digging device comprises first machine arm 1, and The second machine arm 4 hinged by the first machine arm 1 telescopically installs the telescopic arm 5 in the second machine arm 4; the hydraulic system includes a third hydraulic cylinder arranged between the telescopic arm 5 and the second machine arm 4 7. The second hydraulic cylinder 3 arranged between the first machine arm 1 and the end of the second machine arm 4 away from the telescopic arm 5 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com