Thermal displacement compensation device for machine tool

A technology of thermal displacement correction and thermal displacement, which is applied in the direction of measuring devices, electrical devices, and heat measurement, can solve the problems of increased cost and failure rate, and the inability to estimate thermal displacement, etc., and achieve the effect of high-precision correction

- Summary

- Abstract

- Description

- Claims

- Application Information

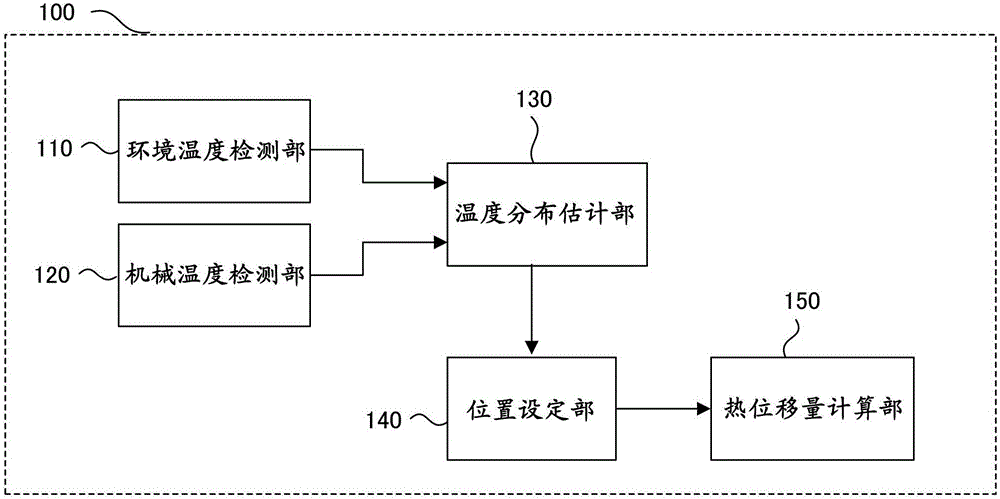

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

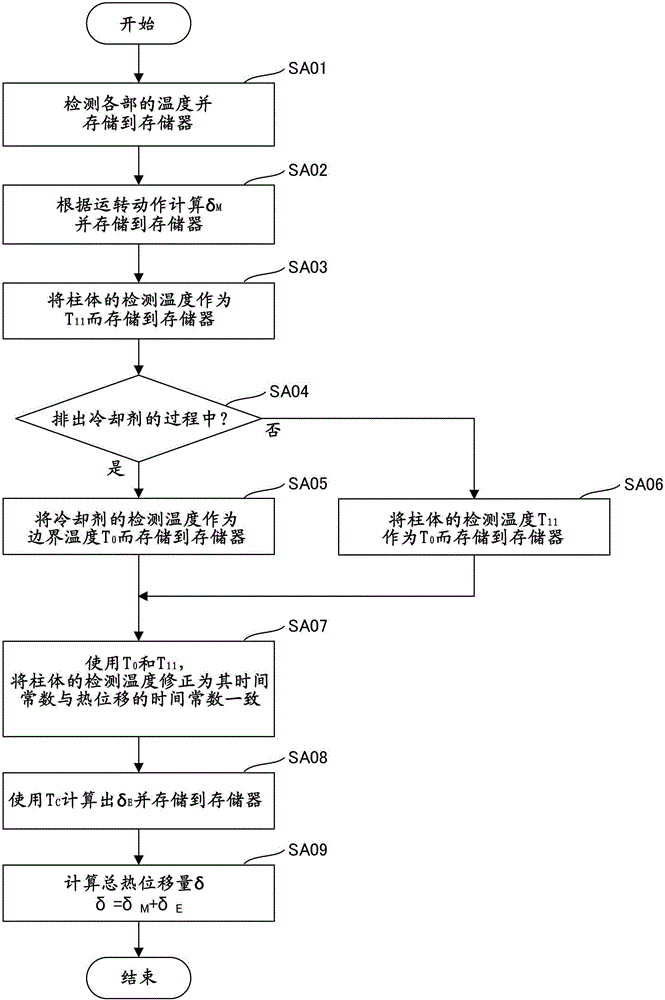

[0044] use image 3 is shown in the flowchart to illustrate the figure 1 performed by the thermal displacement correction device 100, by figure 2 The process of estimating the coolant-induced thermal displacement of machining center 1 is shown.

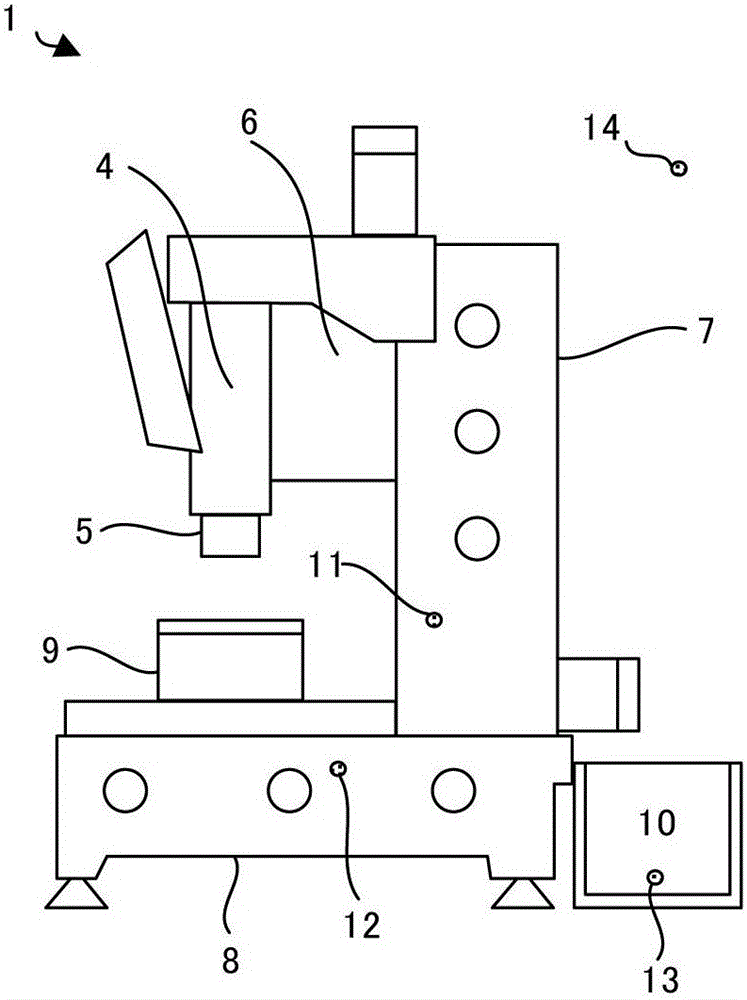

[0045] Repeatedly while the thermal displacement correction function is valid image 3 processing of the flow chart. In this flowchart, the thermal displacement amount δ caused by the change in ambient temperature and the coolant will be E The description will focus on the thermal displacement of the column body 7 , but the thermal displacement of mechanical structural parts such as the machine base 8 and the spindle mounting table 6 can also be estimated and combined by the same method.

[0046] [Step SA01] The temperature of each part is detected by a temperature sensor and stored in a memory. Expected to pass through the thermal displacement of the ball screw and the main shaft part δ M The calculation interval is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com