Lens mechanism

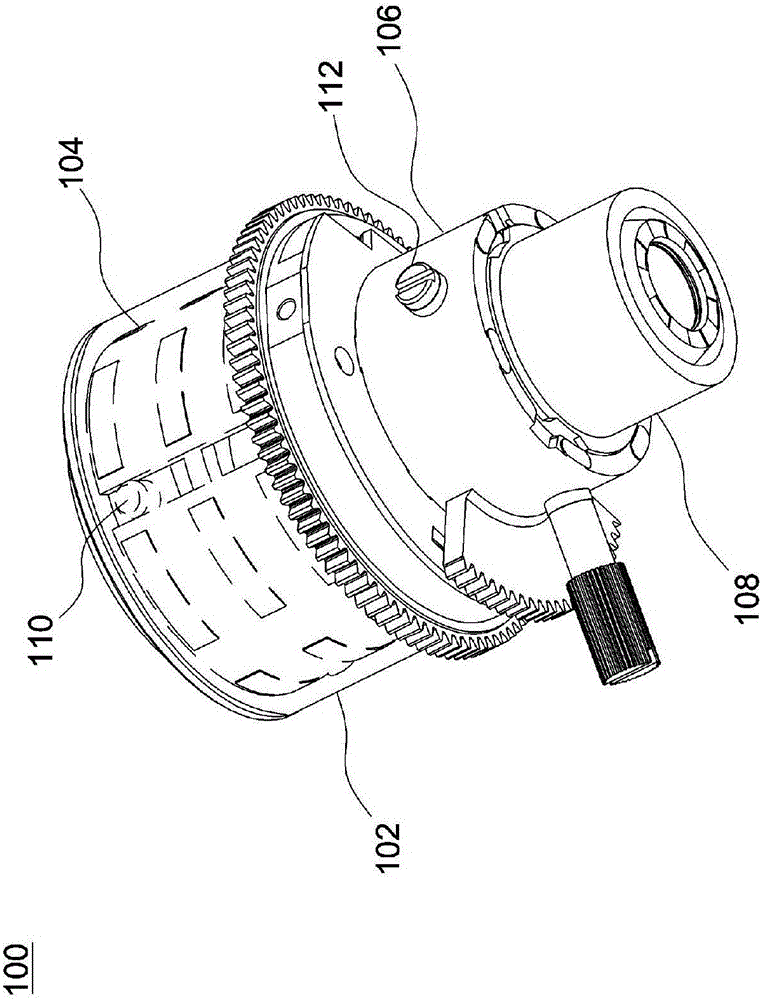

A lens and mechanism technology, applied in the field of lens mechanism, can solve the problems of reducing reliability and limit accuracy, increasing component cost, occupying more space, etc., and achieving the effect of improving reliability and limit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Other purposes and advantages of the present invention can be further understood from the technical features disclosed in the present invention. In order to make the above and other objects, features and advantages of the present invention more clearly understandable, the above and other technical content, features and effects of the present invention will be clear in the following detailed description of the embodiments with reference to the accompanying drawings presentation. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions in the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

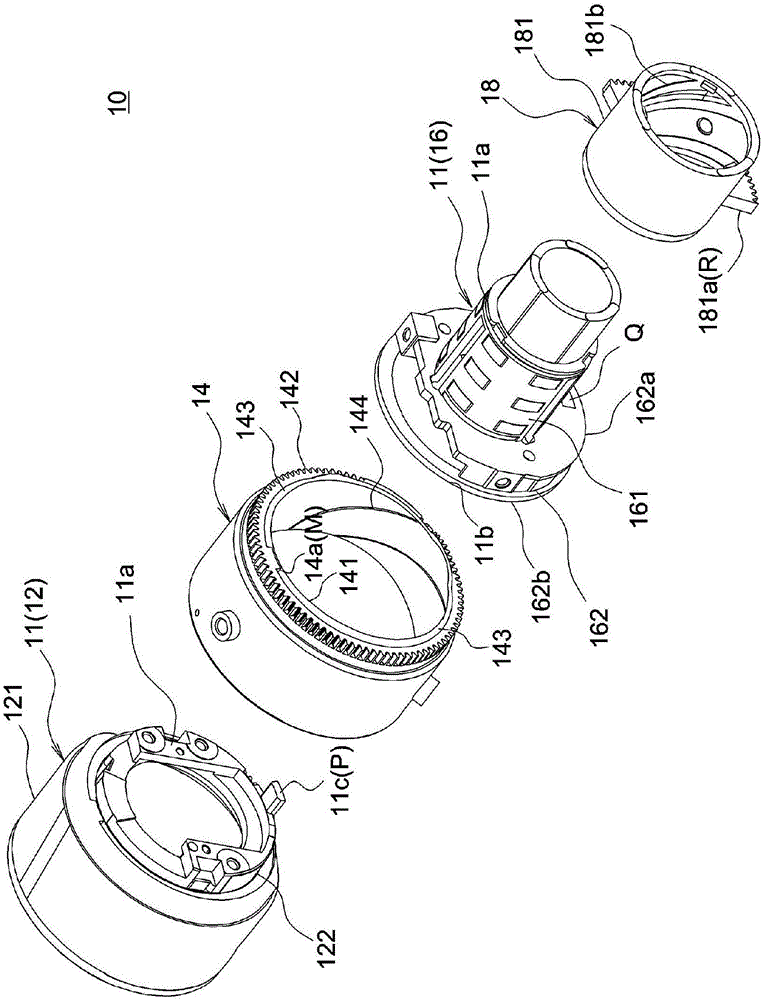

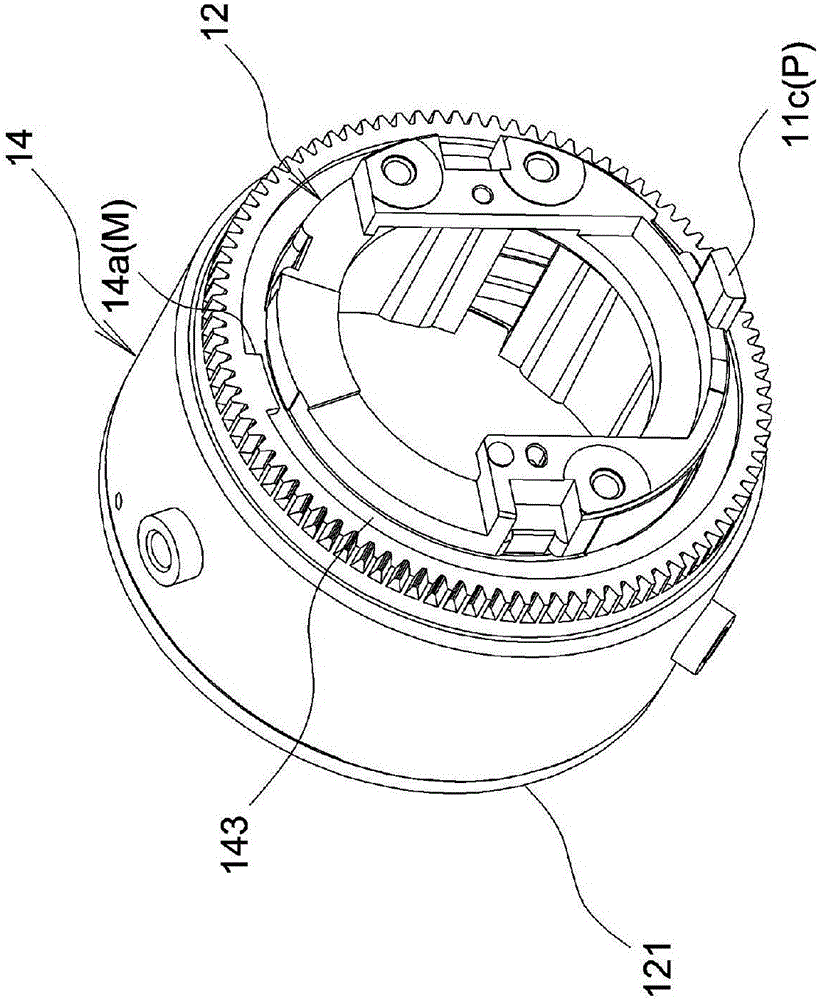

[0078] figure 2 It is an exploded view of the lens mechanism according to an embodiment of the present invention. like figure 2 As shown, a lens mechanism 10 includes a sleeve assembly 11 , a first swivel 14 and a second swivel 18 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com