A gas spring relief valve

A gas spring, relief valve technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of energy waste, affecting the service life of hydraulic system, etc., and achieve the effect of eliminating pressure regulation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

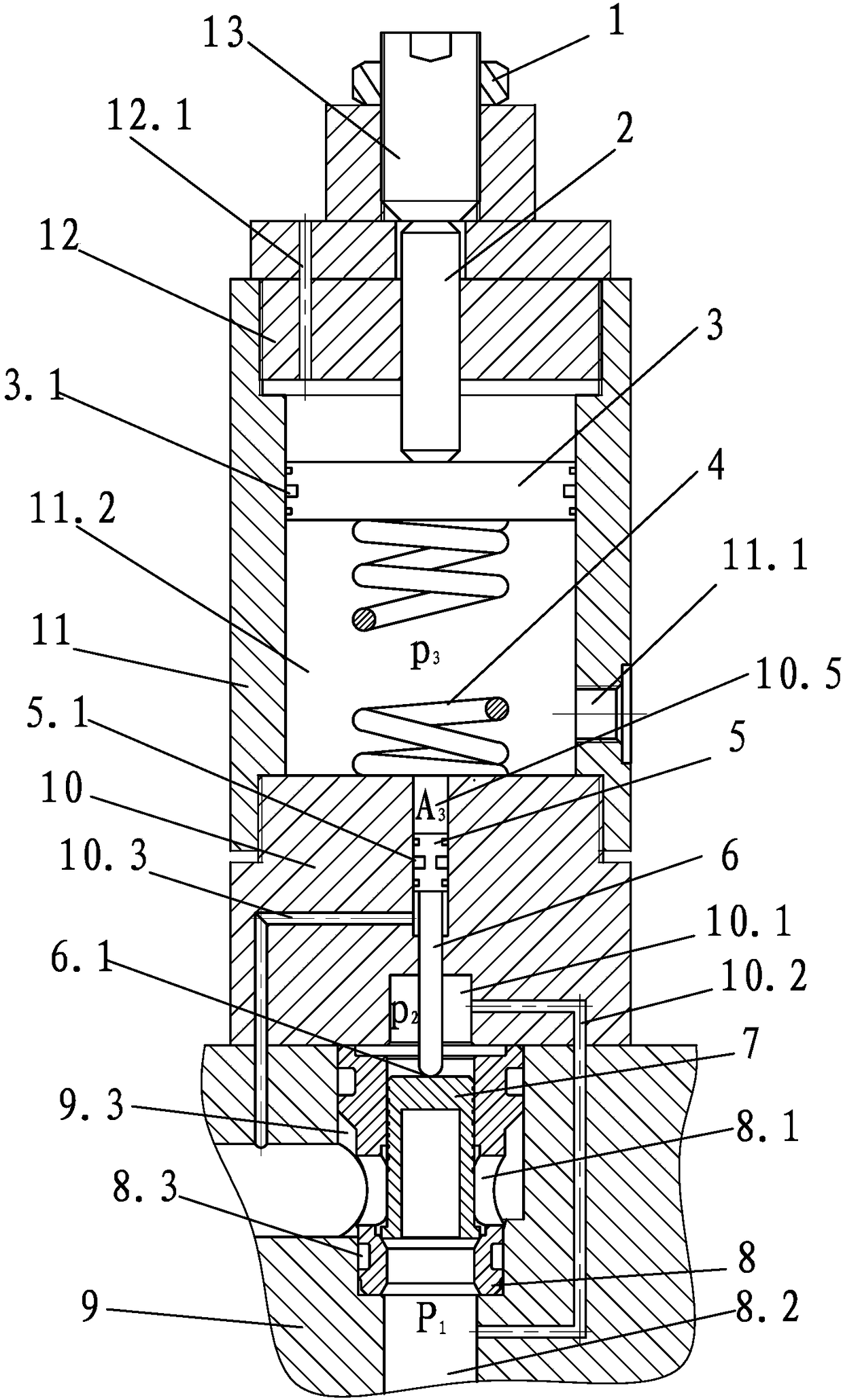

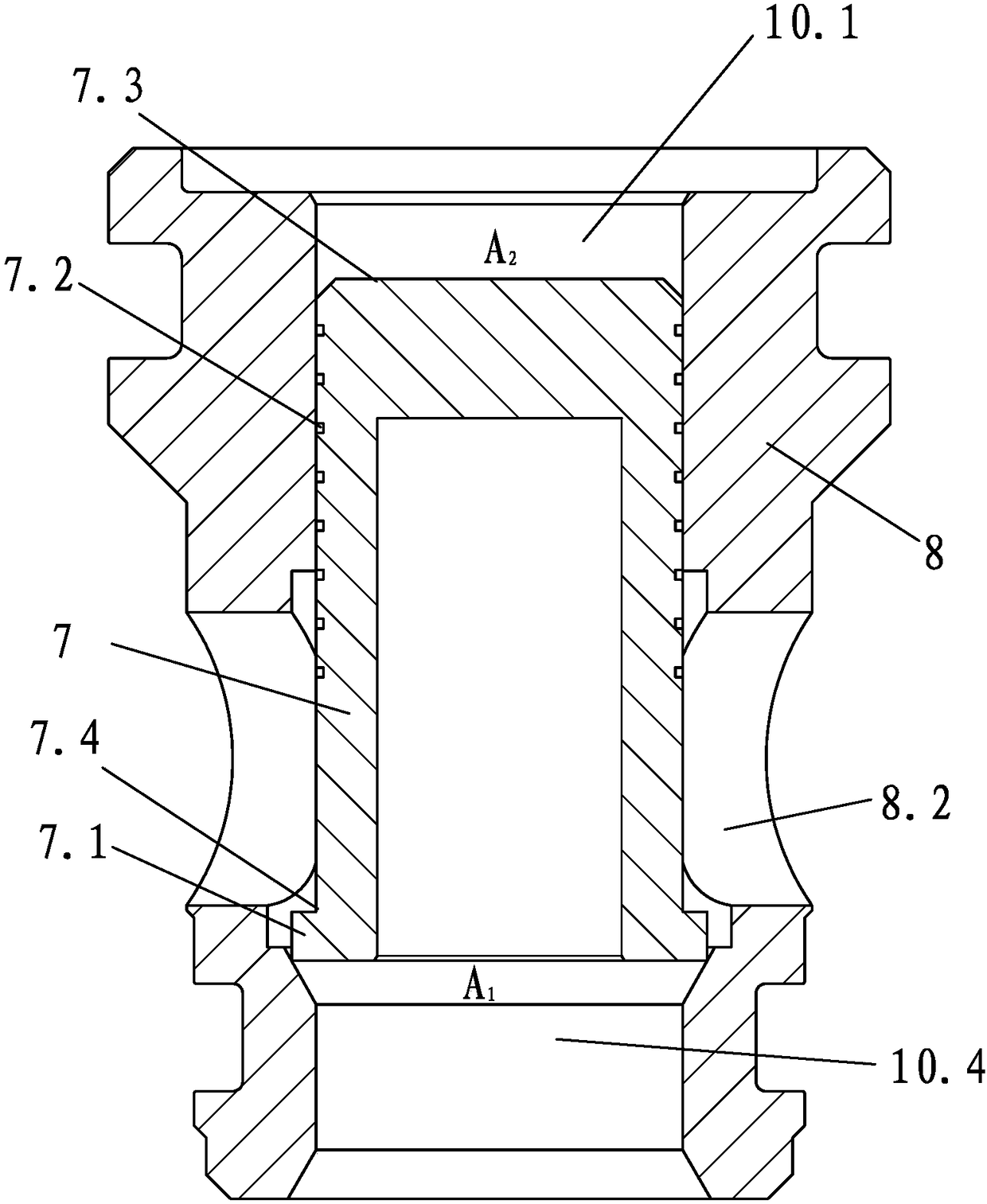

[0039] refer to figure 1 and figure 2 , a gas spring relief valve, including a valve seat 9, a valve chamber 9.3 disposed in the valve seat 9, a valve sleeve 8 disposed in the valve chamber 9.3, a valve core 7 slidably arranged in the valve sleeve 8 and The elastic pressing mechanism against the valve core 7 is provided with an oil inlet 8.2 and an oil outlet 8.1 connected with the valve cavity 9.3 on the valve seat 9. When the oil inlet 8.2 exceeds the set value, the oil will flow The spool 7 lifts up, and the oil flows out from the oil outlet 8.1.

[0040] In the present invention, the elastic pressing mechanism includes a cylinder body 11, a first valve body 12, a second valve body 10, a first piston 3 arranged in the cylinder body 11, and a valve body arranged between the first piston 3 and the second v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com