Control method for macular corrosion of cold rolling pickling machine set

A technology of pickling unit and control method, which is applied in the direction of drying solid materials, spraying devices, and drying solid materials without heating, can solve the problems of strip steel macular corrosion, loss, etc., and achieve the purpose of improving the yield rate, reducing the conversion rate, and reducing The effect of mass objection on macular rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

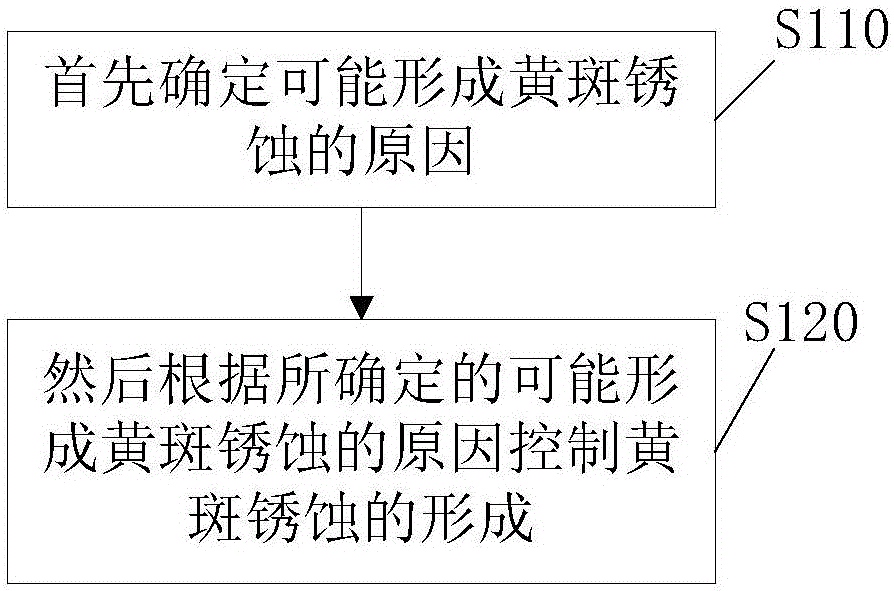

[0025] In order to illustrate the control method of the macular corrosion of the cold-rolled pickling unit provided by the invention, figure 1 The flow chart of the method for controlling macular corrosion of a cold rolling pickling line according to an embodiment of the present invention is shown.

[0026] like figure 1 As shown, the control method of the macular corrosion of the cold-rolled pickling unit provided by the invention comprises:

[0027] S110: Determine possible causes of macular erosion; S120: Control the formation of macular erosion according to the determined possible cause of macular erosion.

[0028] In step S110, the reasons that may form macular corrosion include the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com