A chip punching mechanism of a multi-chip smart card chip packaging device

A smart card chip and packaging device technology, which is applied to electrical components, stone processing tools, electric solid devices, etc., can solve the problems of affecting chip packaging accuracy, affecting packaging speed, and slow packaging speed, so as to save packaging time and improve packaging speed and efficiency, the effect of improving packaging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

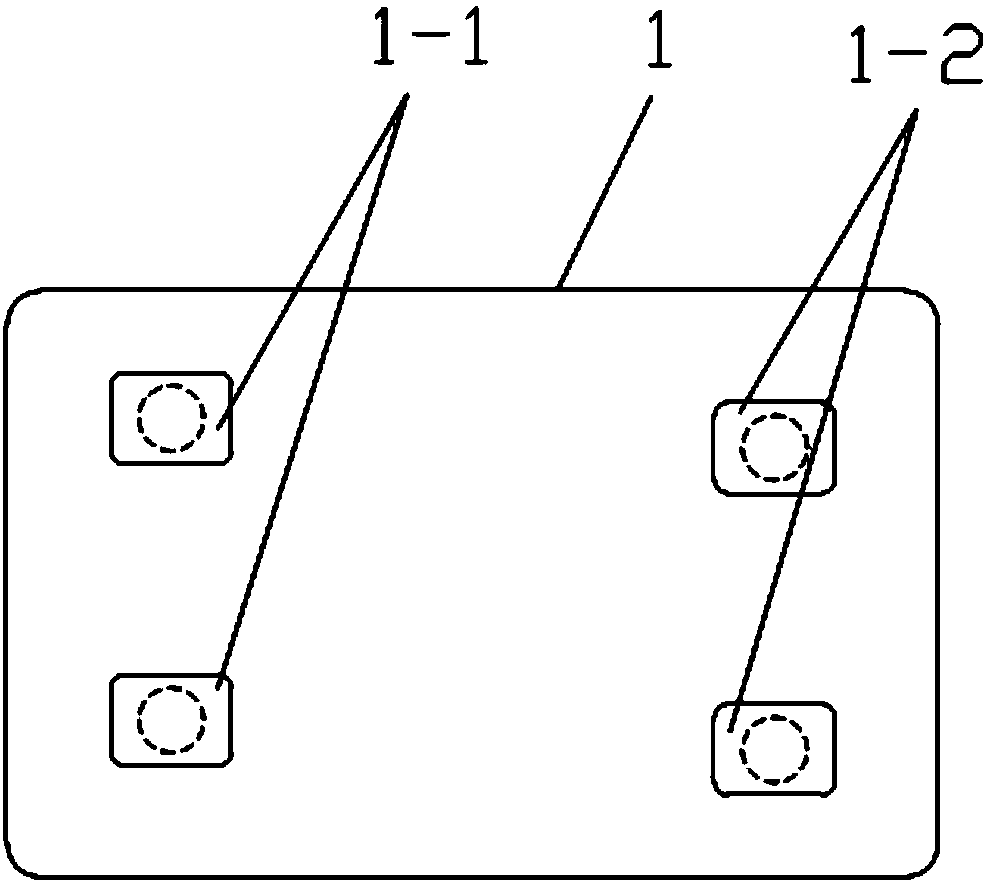

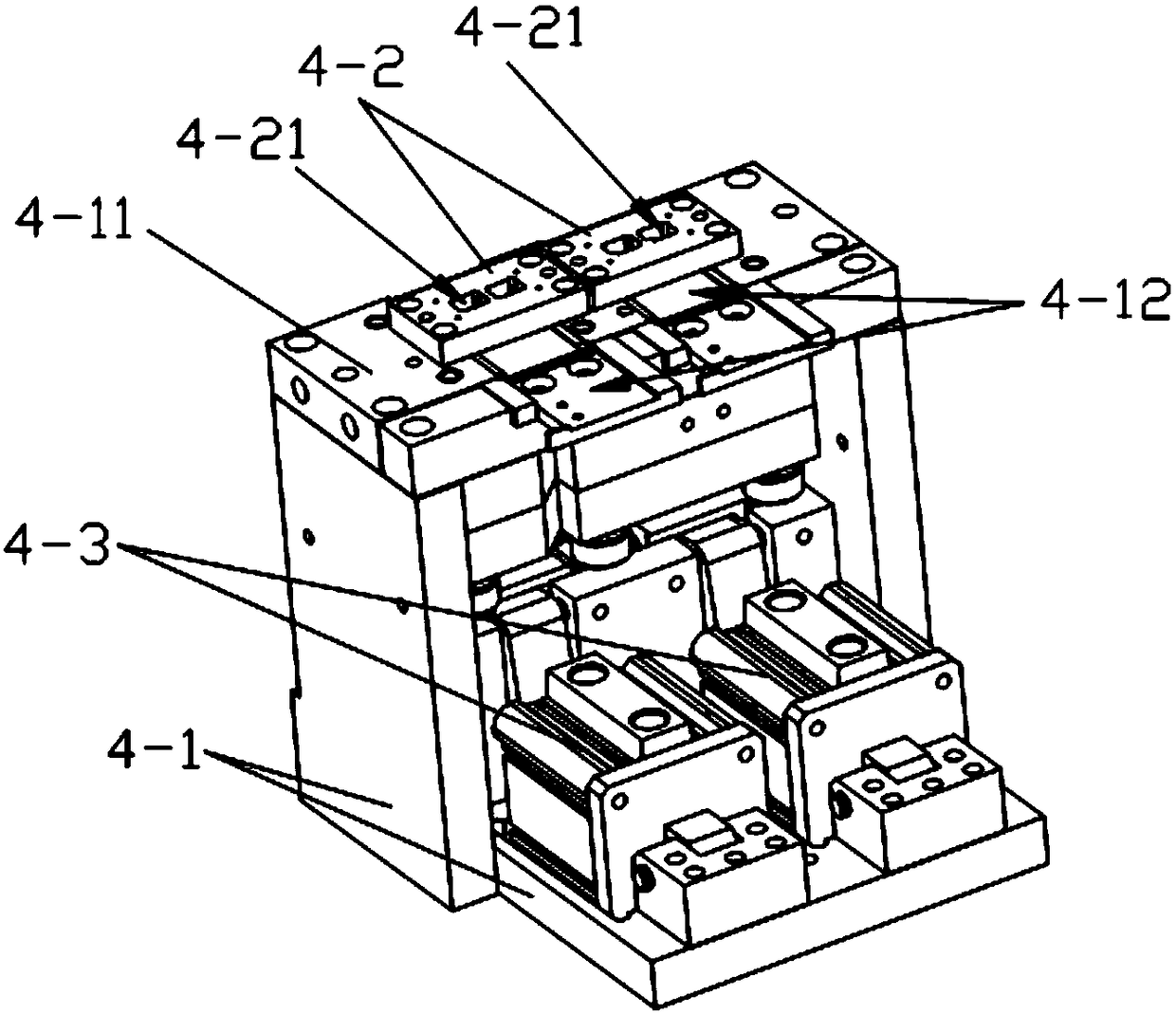

[0027] see figure 2 The chip punching mechanism 4 of the multi-chip smart card chip packaging device of the present invention is two arranged side by side, and each chip punching mechanism 4 includes a punching die 4-2 and a punching die set below the punching die 4-2. As for the actuator, two punching holes 4-21 are arranged in each punching die 4-2; two chip strips (not shown) respectively pass under the two punching dies 4-2, and the chips in the two chip straps The orientations differ by 180°.

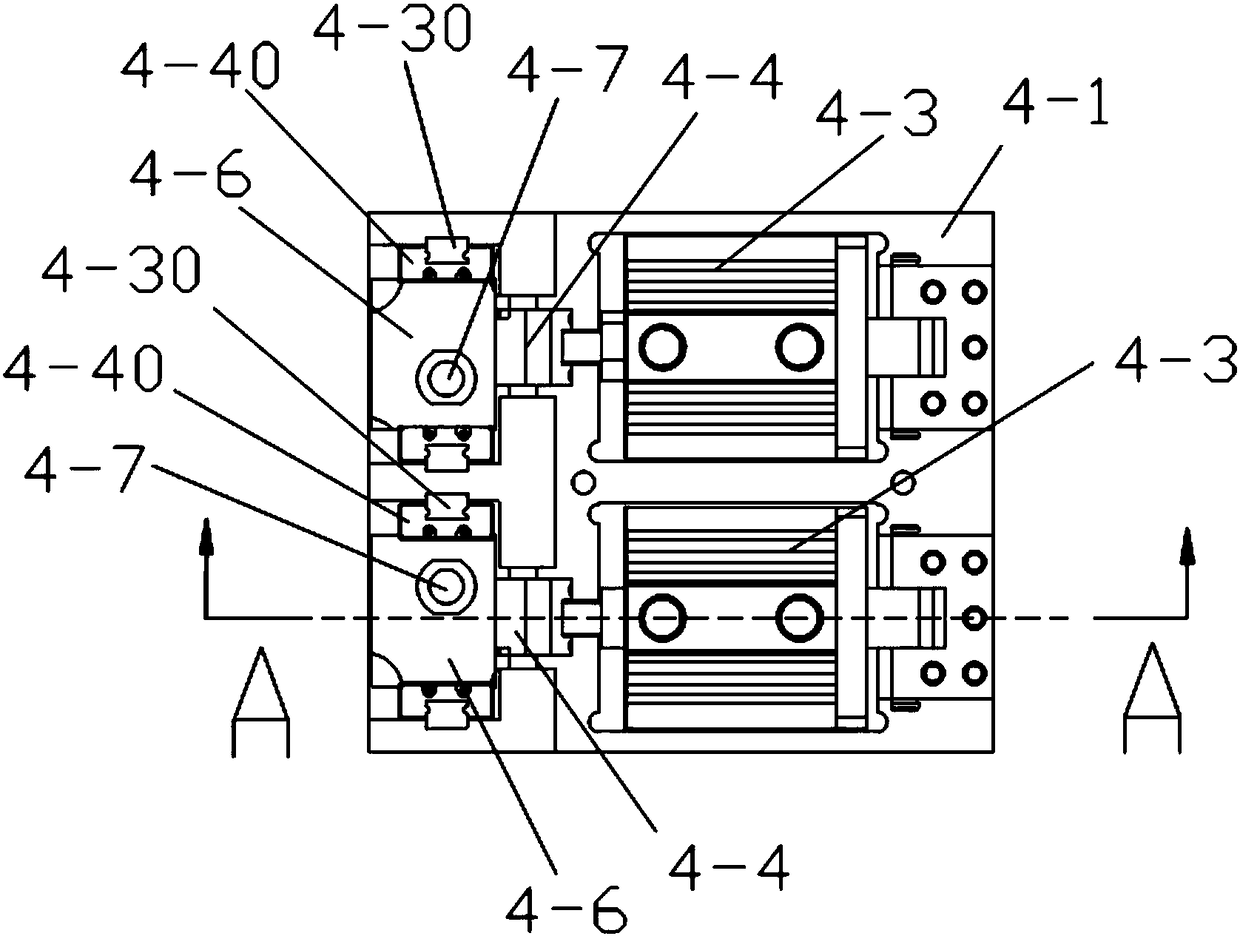

[0028] see Figure 2-Figure 8 , in each chip punching mechanism 4, the punching executive mechanism includes a punching bracket 4-1, a punching rod 4-10 for punching the chip out of the chip belt, and a fixed punching rod 4 -10 punching rod holder 4-8 and the punching dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com