Die for welding steel tube and sleeve and use method thereof

A technology for welding steel pipes and sleeves, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of prolonging the construction period, difficult operation, and weak welding, so as to reduce the difficulty of construction and the scope of application Extensive, easy-to-control effects on welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

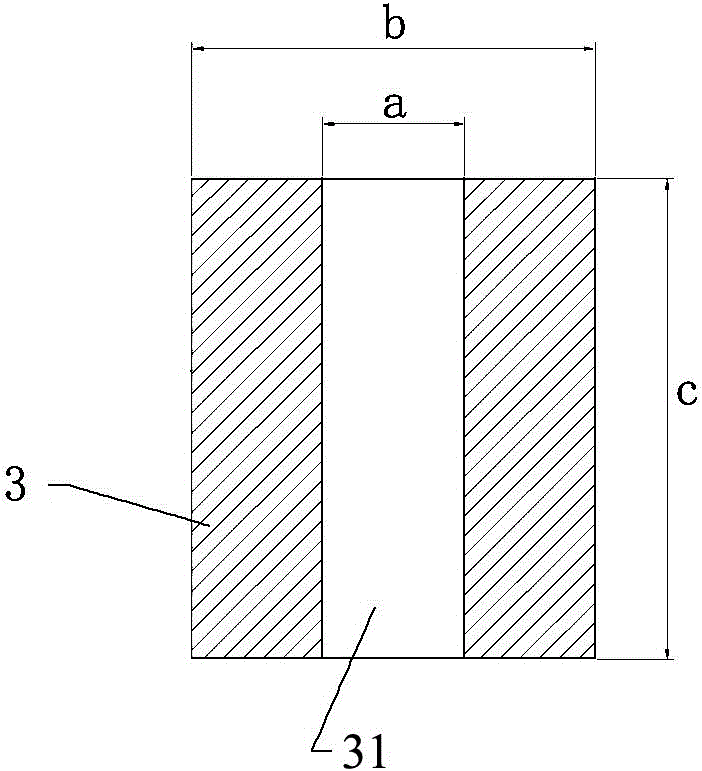

[0027] Such as figure 2 As shown, the dimensions of the socket head 3 in the mold for welding steel pipes and casing pipes of the present invention are shown in Table 1.

[0028] Table 1 Dimensions of sleeve

[0029] mmabc SC1510.0021.2533.50 SC2010.0026.7542.25 SC25 10.0023.37536.85

[0030] As shown in Table 1, a is the diameter of the hole 31 of the socket 3, b is the diameter of the socket 3, and c is the height of the socket 3.

[0031] The specific use method of the mold for welding steel pipes and casing pipes of the present invention is as follows:

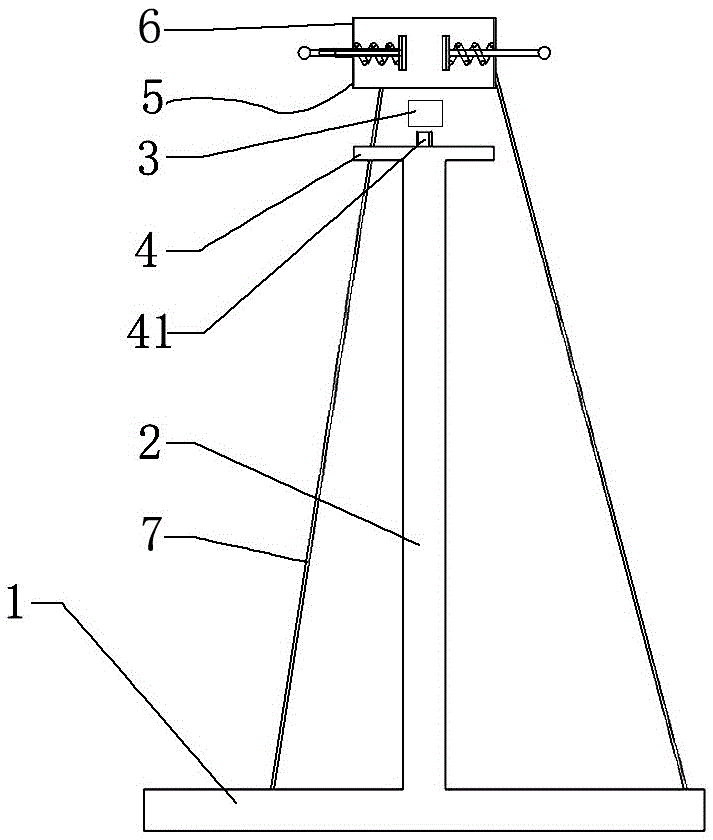

[0032] According to the specifications of the welded steel pipe, select a suitable socket 3, tighten the socket 3 and the support column 2, insert the casing to be welded into the outer bottom of the socket 3. The inner diameter of the casing matches the outer diameter of the socket 3, and then The welded steel pipe is inserted into the casing and abuts against the top surface of the sleeve head 3. At this time, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com