Experimental device and experimental method for linear dynamic sealing characteristics of sealing rings

An experimental device and sealing ring technology, which is used in machine sealing ring testing, measuring devices, and mechanical devices, etc., can solve problems such as failure to meet requirements, large errors in the friction characteristics of sealing rings, and inability to measure the dynamic friction characteristics of sealing rings. Convenience, small error, convenient experimental research effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

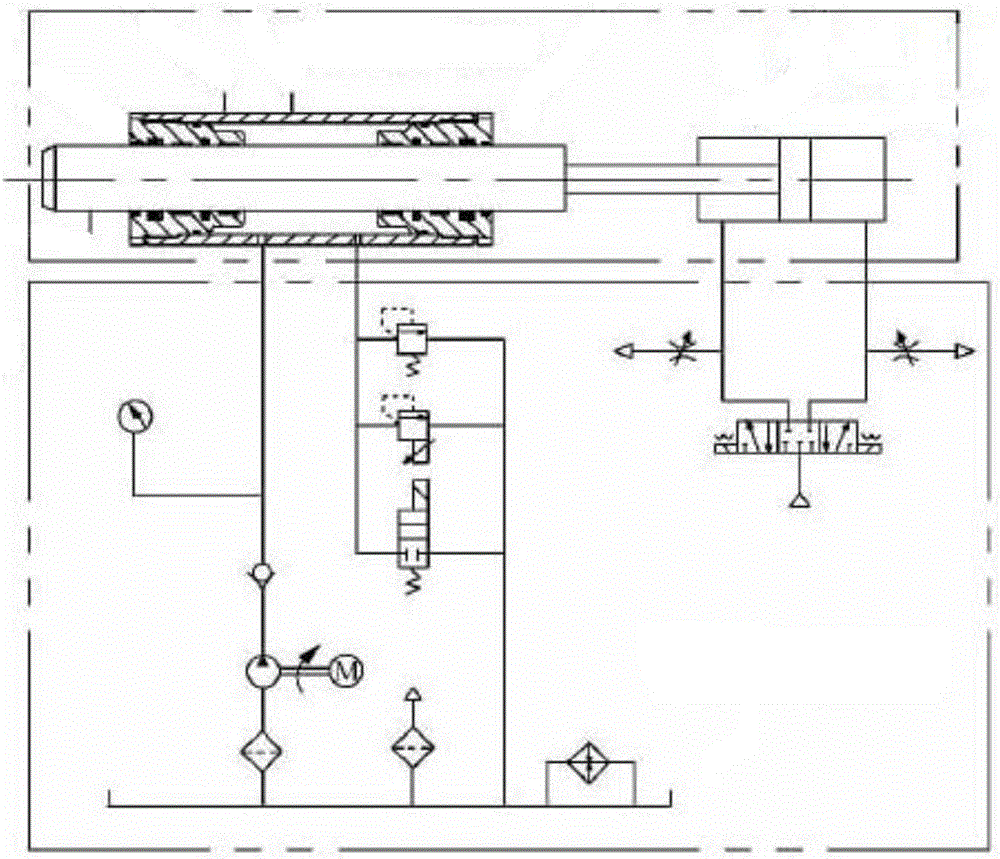

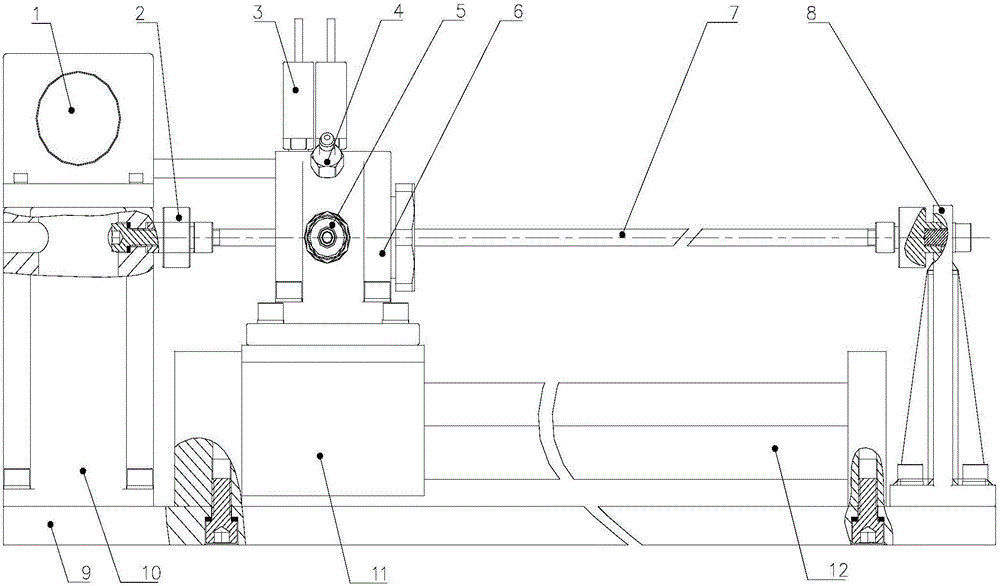

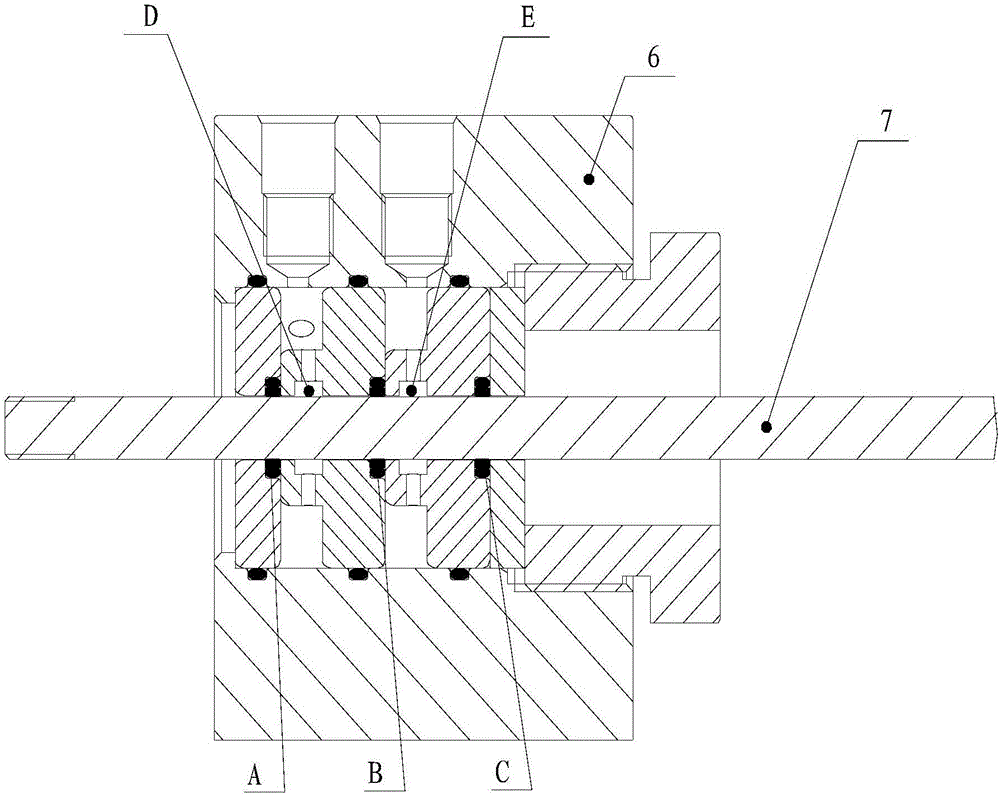

[0042] Example 1, such as figure 2 As shown, the present embodiment discloses an experimental device for linear dynamic sealing characteristics of a sealing ring. The experimental device includes a base 9 on which a rodless cylinder 12 is installed. There is a shaft 7 on the top of the rodless cylinder 12. The shaft 7 One end of one end is connected with the support 10 fixed on the base 9 through the tension pressure sensor 2, and the other end is connected with the bracket 8 fixed on the base 9, and a sleeve assembly 6 is set on the shaft 7, and the sleeve assembly 6 The bottom is fixedly connected with the slide block 11 on the rodless cylinder 12; as image 3 As shown, three sealing ring installation parts A, B, and C are arranged at intervals along the shaft 7 inside the sleeve assembly 6. After the sealing ring is installed in the sealing ring installation part, it can move back and forth along the shaft 7 with the sleeve assembly 6. The sleeve assembly 6. There is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com