High-power sewage pump impeller structure

A sewage pump, high-power technology, applied in the field of high-power sewage pump impeller structure, can solve problems such as fracture and impeller deformation, and achieve the effects of high strength, avoiding deformation or fracture, and high sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

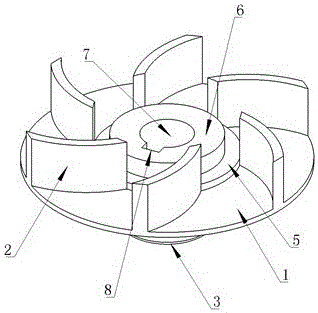

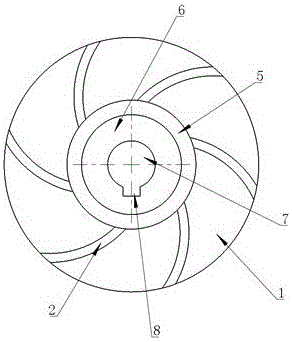

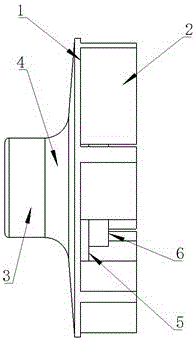

[0017] like Figure 1 to Figure 3 As shown, a high-power sewage pump impeller structure is suitable for high-power sewage pumps and can provide higher working efficiency for the sewage pumps. It includes a cylindrical main structure 1, an impeller blade 2 integrally formed with the cylindrical main structure 1, and an assembly shaft 3. The cylindrical main structure 1 and the assembly shaft 3 are connected together through a main body reinforcement structure 4. The present invention The impeller structure of the high-power sewage pump is integrally formed, and the processing is convenient, the production efficiency of parts is high, and the overall cost can be controlled within a reasonable range. The outermost edge of the impeller blade 2 is the same as the upper edge of the cylindrical main structure 1, and the maximum amount of sewage can be realized during the sewage discharge process. The number of the impeller blades 2 is 6 and they are evenly divided into the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com