Prefabricated component composite wall and its installation method

A technology of prefabricated components and walls, applied in the direction of fences, building types, buildings, etc., can solve the problems of poor wind resistance, non-reusable, slow assembly speed, etc., to save costs, reduce project costs, and beautify the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

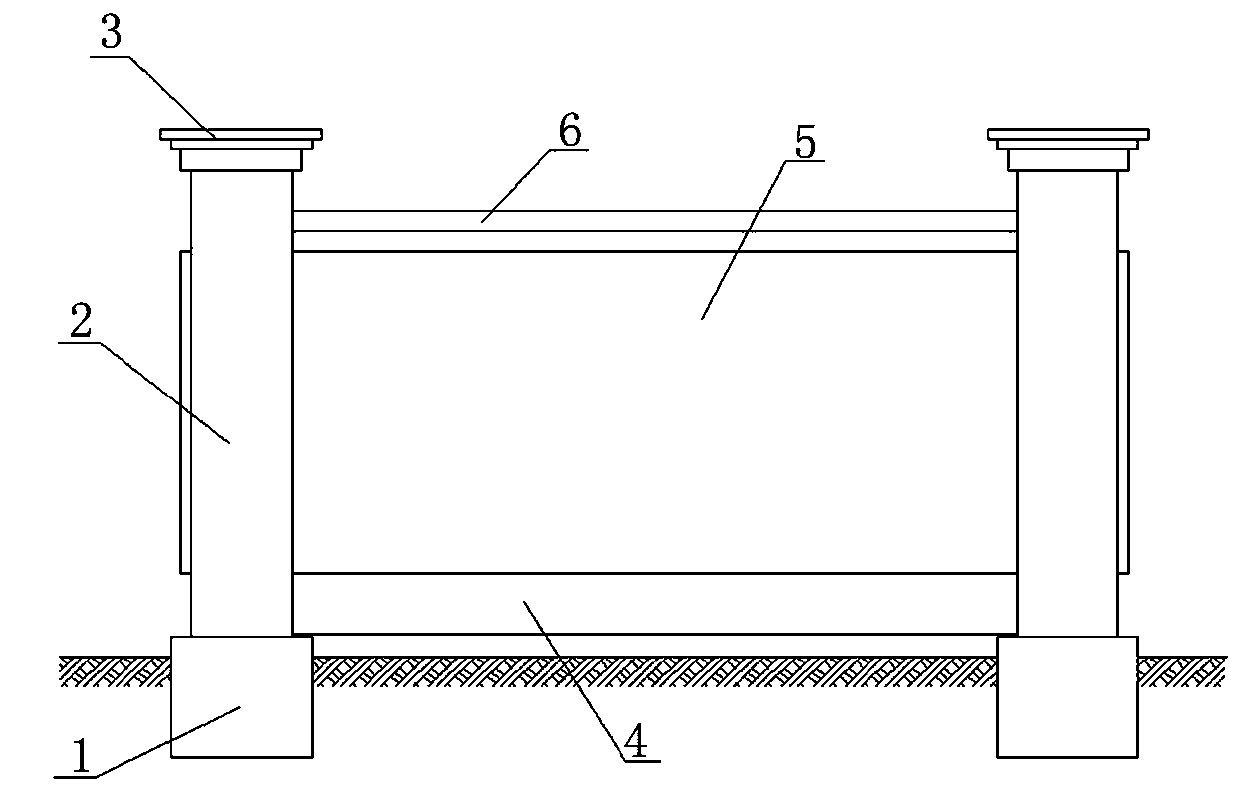

[0037] Examples see figure 1 As shown, this prefabricated component composite wall includes a foundation 1, a column 2, a column cap 3, a bottom beam 4, a wall panel 5 and a wall cap 6. The foundation 1, column 2, column cap 3, bottom beam 4, wall panel 5 and wall cap 6 are all prefabricated parts, and new wall materials such as magnesium chloride, perlite, sand, cement, etc. can be used in accordance with scientific proportions and special production processes It can effectively improve the manufacturing accuracy of prefabricated components, enhance the interchangeability of prefabricated components, and meet the requirements of convenient assembly.

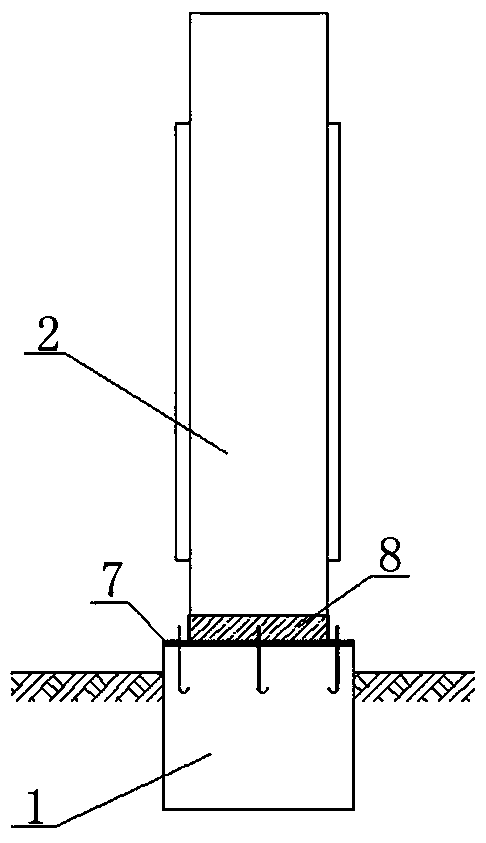

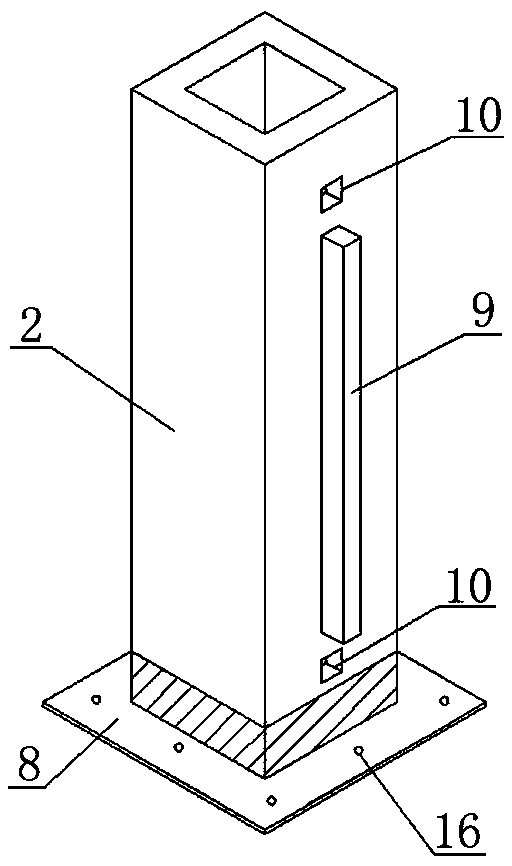

[0038] see figure 2 As shown, the foundation 1 is buried underground, and a foundation embedded part 7 is placed on the foundation 1, and a vertically upward prefabricated bolt 17 is welded on the foundation embedded part 7. The foundation is poured with concrete, and the foundation embedded parts 7 are placed. If it is winte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com