Method for antistatic floor construction for machine room

A construction method and anti-static technology, applied in local raised floors, floors, covering/lining, etc., can solve the problems of prolonging the construction period, increasing the construction cost, deviation of the floor position of the machine room, etc., reducing the workload and increasing the stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

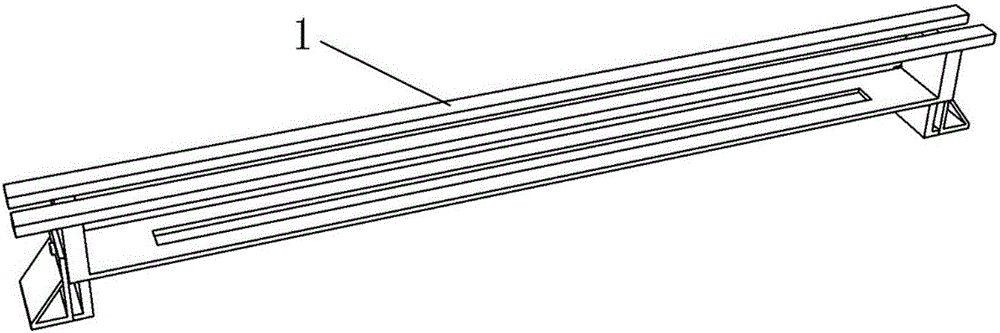

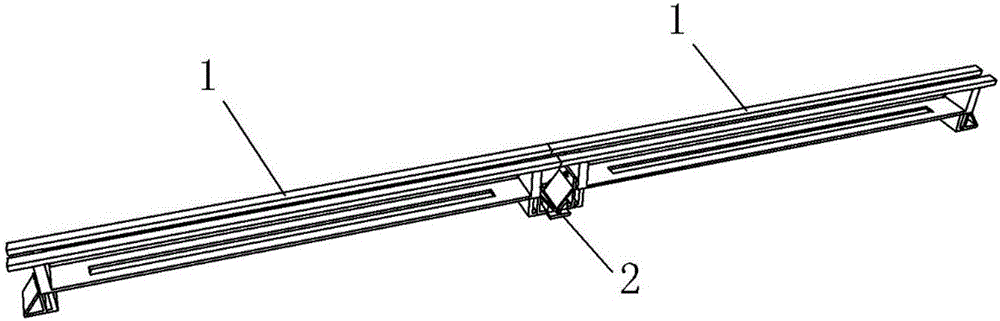

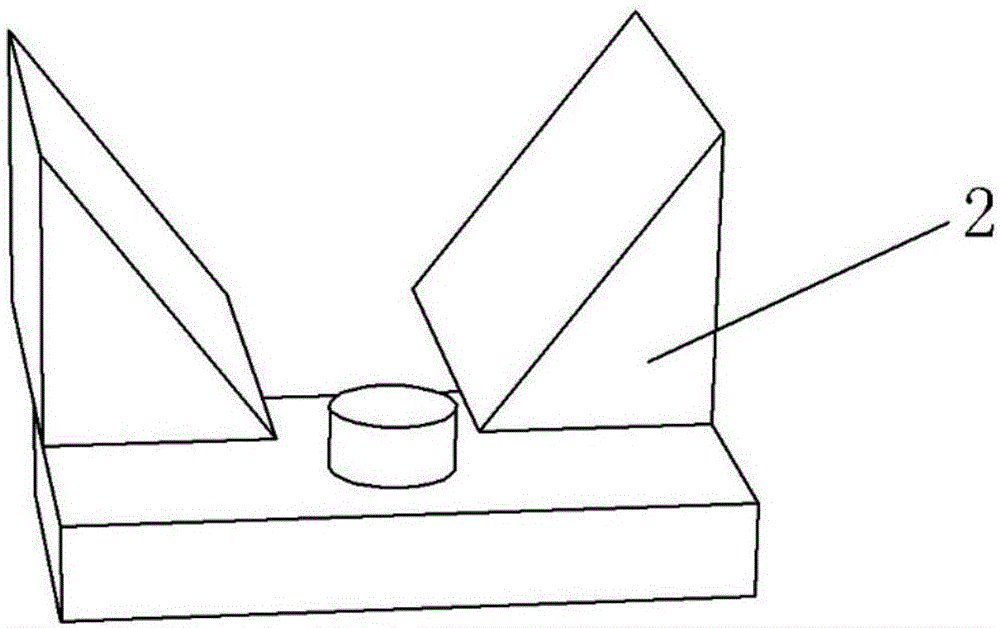

[0039] Such as Figure 1 to Figure 9 Shown, a kind of antistatic floor construction method that the present invention is used for machine room comprises the following steps:

[0040] (a) Construction preparation: technicians inspect the site and check the flatness of the ground base at the same time. Before laying the antistatic floor, the ground can be pretreated well. Then brush the special floor paint for the machine room twice. Draw the overall structure of the computer room, arrange the antistatic floor according to the overall structure of the computer room and the distribution position of the infrastructure, and draw the specific distribution location of the devices involved in the installation of the antistatic floor, and then transport the materials involved in the installation to the construction site , and concentrate on stacking.

[0041] (b) Positioning and setting out: According to the drawings, determine the installation position of the antistatic floor in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com