Multipurpose attaching machine for 3D glass curved screens

A laminating machine and glass technology, applied in packaging and other directions, can solve problems such as inability to bond curved glass and film, easy to cause air bubbles in lamination, and affect the appearance of mobile phones, etc., to achieve good cavity sealing effect, precise glass positioning, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

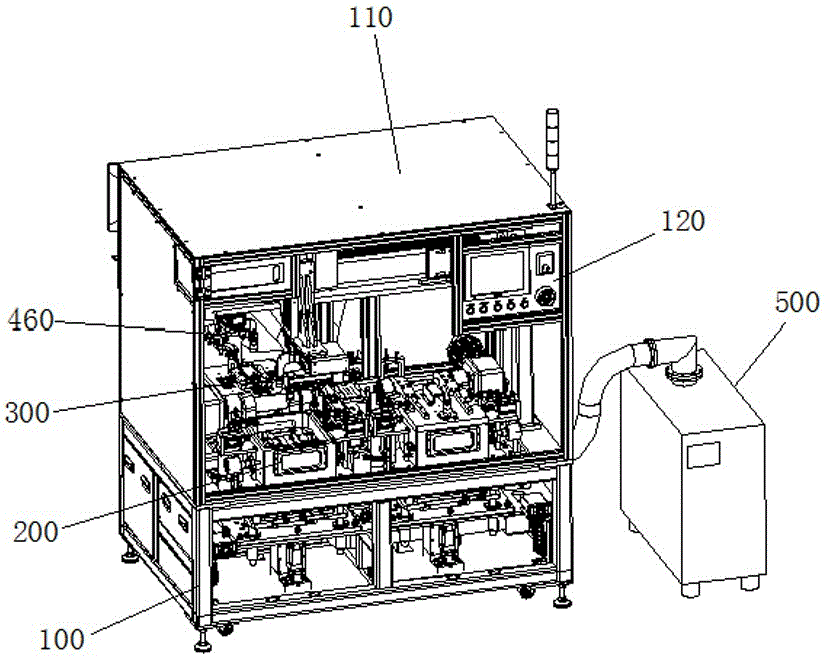

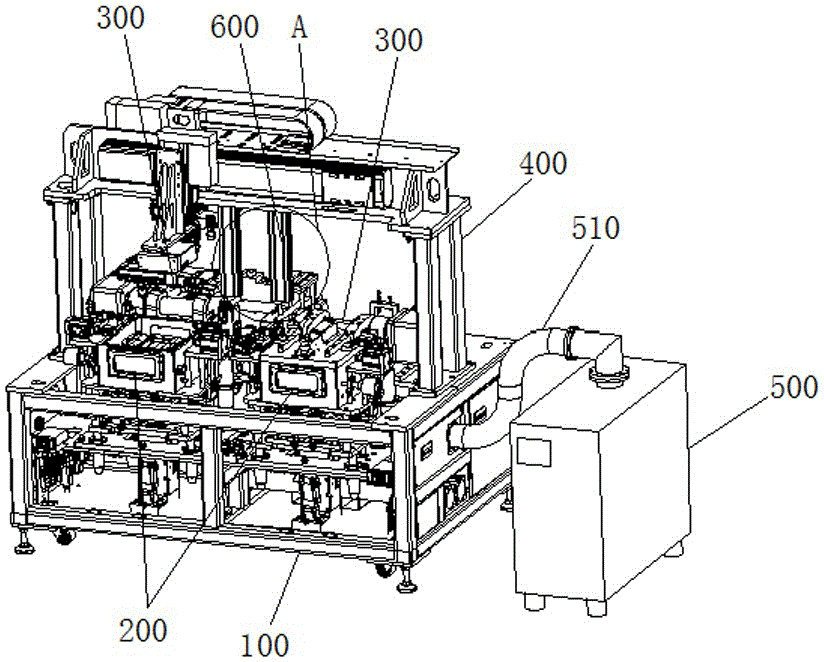

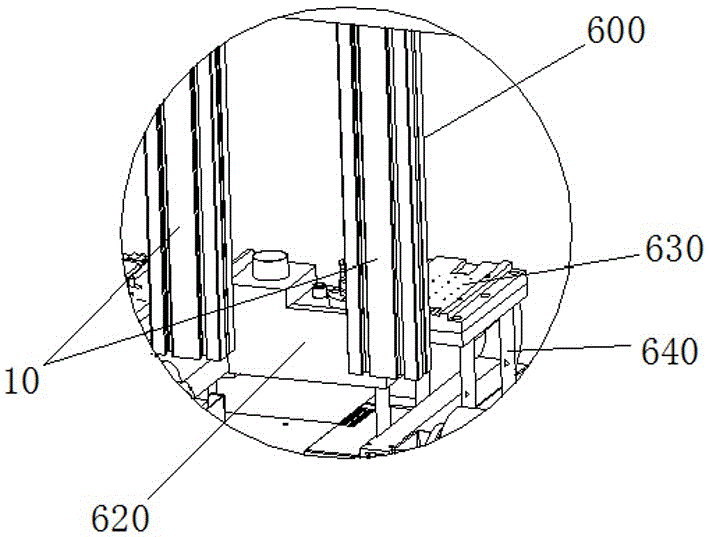

[0040] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 11 and Figure 12 As shown, a 3D glass curved screen multi-purpose laminating machine includes a frame 100, an upper shield 110 is arranged above the frame 100, an operation panel 120 is arranged on one side of the upper shield 110, and the machine The frame 100 is provided with: two sets of vacuum chambers 200, which are arranged side by side on the front side of the frame 100, and the vacuum chambers 200 are used for placing, positioning, fine-tuning and sealing of the film protective film. The vacuum chambers 200 are all sealed chambers 210, the sealed chambers 210 are installed on the chamber frame 280, the film protective film po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com