A bionic underground digging robot

A robot and habitat technology, applied in the field of bionic robots, can solve the problems of low excavation and walking efficiency, and achieve the effects of high excavation efficiency, flexible movement and good work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

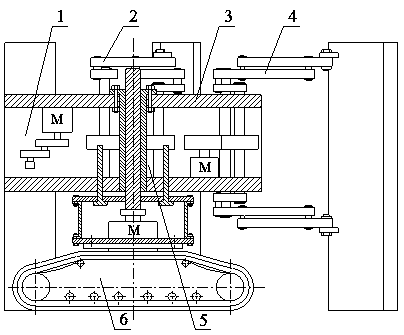

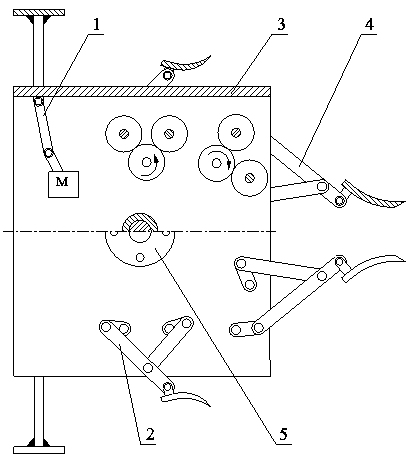

[0041] A bionic underground digging robot. Such as figure 1 and figure 2 As shown, the bionic underground excavation robot is composed of a crawler walking device 6 , a lifting mechanism 5 , a body 3 , two bucket mechanisms 4 , two bucket mechanisms 2 and two extrusion mechanisms 1 . For the sake of description respectively, it is assumed that the forward direction of the bionic underground excavating robot is the front, and the left side facing the forward direction is the left. Such as figure 1 and figure 2 As shown, the lifting mechanism 5 is fixed at the center position of the upper part of the crawler belt traveling device 6 , and the upper part of the lifting mechanism 5 is fixedly connected with the center position of the upper part of the body 3 . Bucket mechanism 4 is installed symmetrically on both sides of the body 3 front portion, bucket mechanism 2 is installed symmetrically on both sides of the body 3 middle portion, and extrusion mechanism 1 is symmetrical...

Embodiment 2

[0059] A bionic underground digging robot. Except following technical parameter, all the other are with embodiment 1:

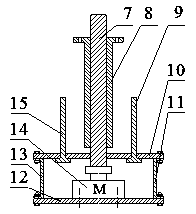

[0060] 3 or 5 small holes are evenly arranged near the threaded flange mounting hole 22, and the 3 or 5 small holes are located on the same circumferential line;

[0061] The flange is evenly provided with 3 or 5 small holes, and the 3 or 5 small holes are located on the same circumferential line. The 3 or 5 small holes of the threaded flange 8 are correspondingly connected with the 3 or 5 small holes provided on the body top plate 17 by bolts.

[0062] Compared with the prior art, this specific embodiment has the following positive effects:

[0063] The lifting mechanism of this specific embodiment is fixed at the center position of the upper part of the crawler belt traveling device, and the upper part of the lifting mechanism is fixedly connected with the center position of the upper part of the body; the bucket mechanism is symmetrically installed on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com