Special transportation flat car for subway steel rails and use method of car

A technology for rails and flat cars, applied in the field of rail transportation, can solve the problems of hidden safety hazards, low single-vehicle transportation volume, and rising basic costs, and achieve the effects of improving work efficiency, saving procurement costs, and high economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

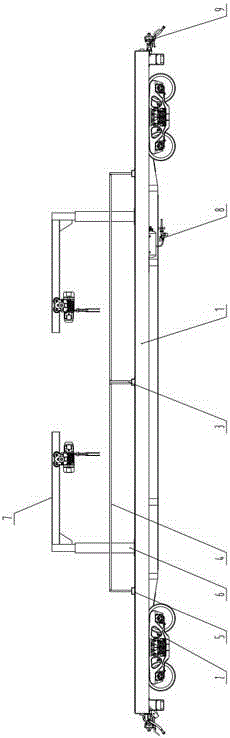

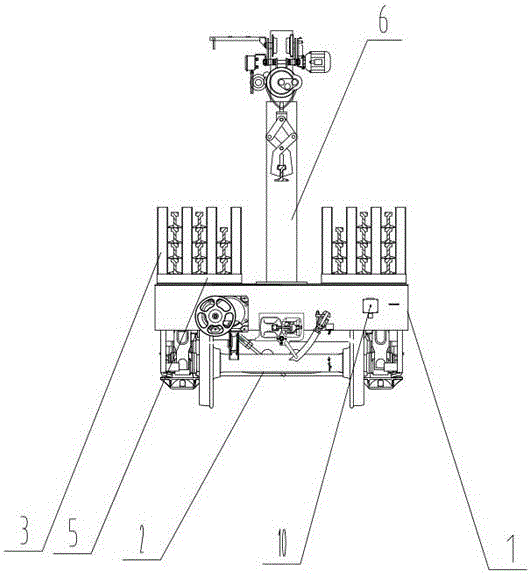

[0019] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: as figure 1 with figure 2 Shown is a special transport flat car for subway rails. The flat car includes an underframe 1, a bogie 2, a rail fixing mechanism, and a rail loading and unloading mechanism. The two bogies 2 are respectively arranged at both ends of the underframe 1. , The upper surface of the underframe 1 is provided with a steel floor, the rail fixing mechanism and the rail loading and unloading mechanism are both arranged on the steel floor, and the rail loading and unloading mechanism is motor-driven.

[0020] The rail fixing mechanism comprises a spacer post 3, a connecting rod 4 and a base 5, and three rows of spacer posts 3 are evenly spaced along the length direction of the undercarriage 1 on the underframe 1, and the quantity of each row of spacer post 3 is Four, three limit columns 3 in the same corresponding position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com