A reciprocating shaver with variable angle driving structure

A driving structure and reciprocating technology, which is applied in metal processing and other directions, can solve the problems of uncomfortable use, inability to change angles, and unsatisfactory products to consumers, and achieve the effect of clean shaving and comfortable grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. The embodiments of the present invention are only used to illustrate the technical solutions of the present invention but not to limit the protection scope of the present invention.

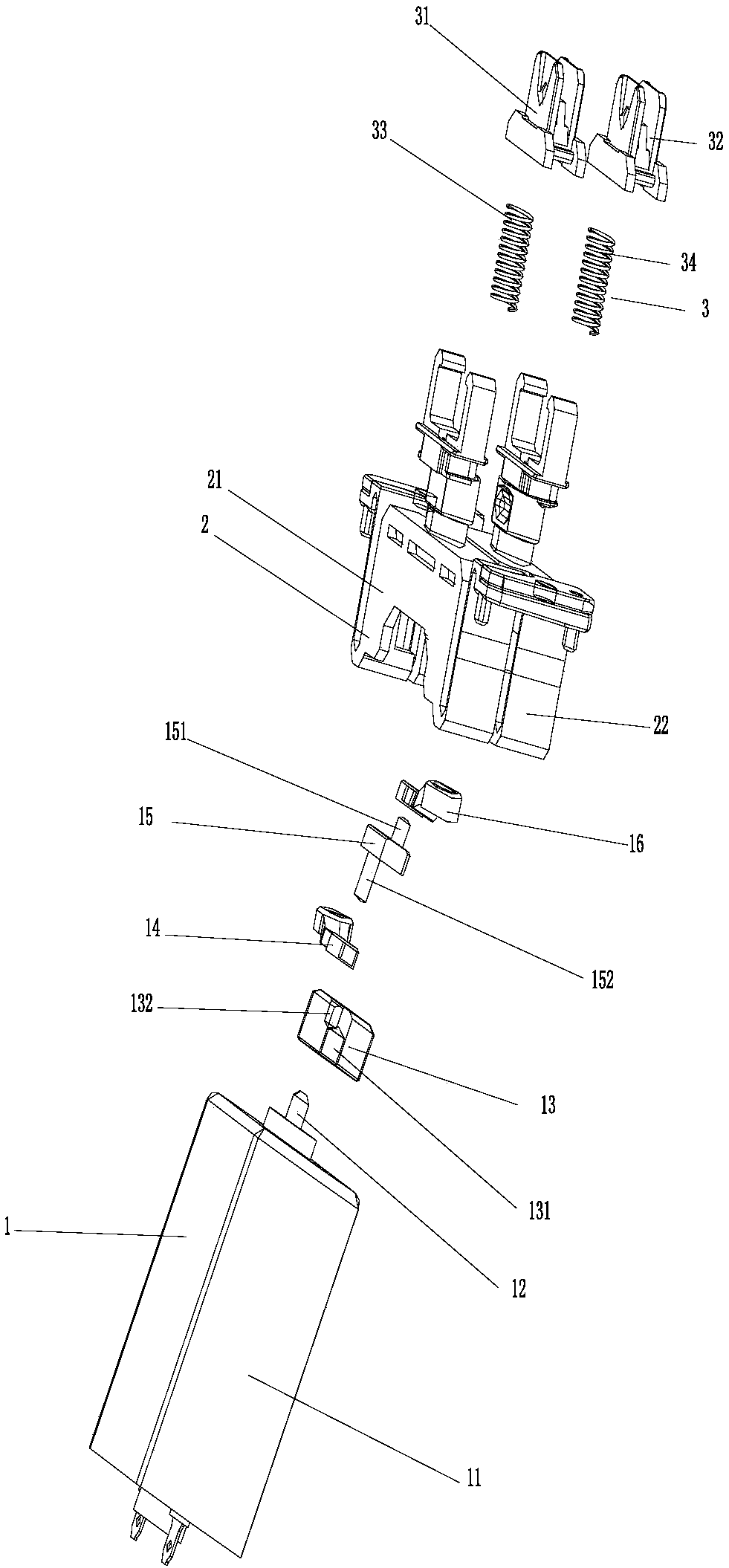

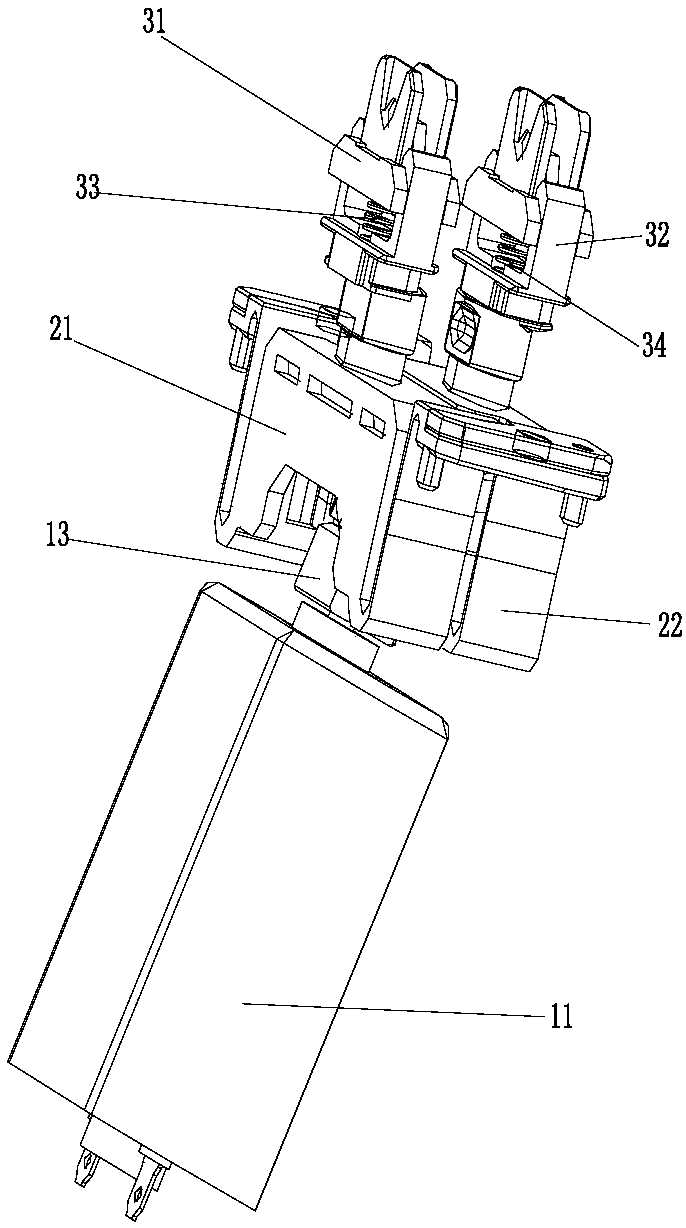

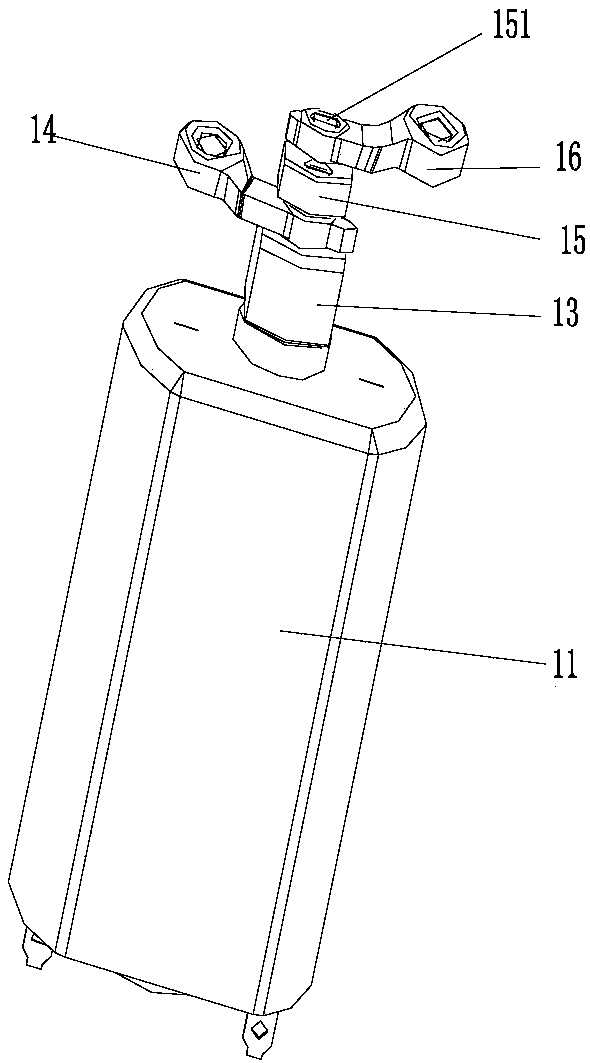

[0012] Such as figure 1 , figure 2 , image 3 As shown, the reciprocating shaver of a kind of variable-angle driving structure provided by the present invention comprises a driving group 1, a driver 2, and a cutter head holder 3, and the driving group 1 includes a micromotor 11 and is sequentially installed on a micromotor shaft 12 The main eccentric wheel 13, the first drive link 14, the upper eccentric wheel 15, the second drive link 16; the driver 2 includes the first driver 21, the second driver 22, the first driver 21 and the first driver The connecting rod 14 is connected, and the second driver 22 is connected with the second driving link 16; the cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com