Checking fixture for wedge-shaped box cover of generator set

A generator set and wedge box technology, applied in the direction of using mechanical devices, mechanical measuring devices, instruments, etc., can solve the problems of not meeting the production requirements, long detection time, coaxiality error, etc., and achieve convenient and fast detection, simple structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

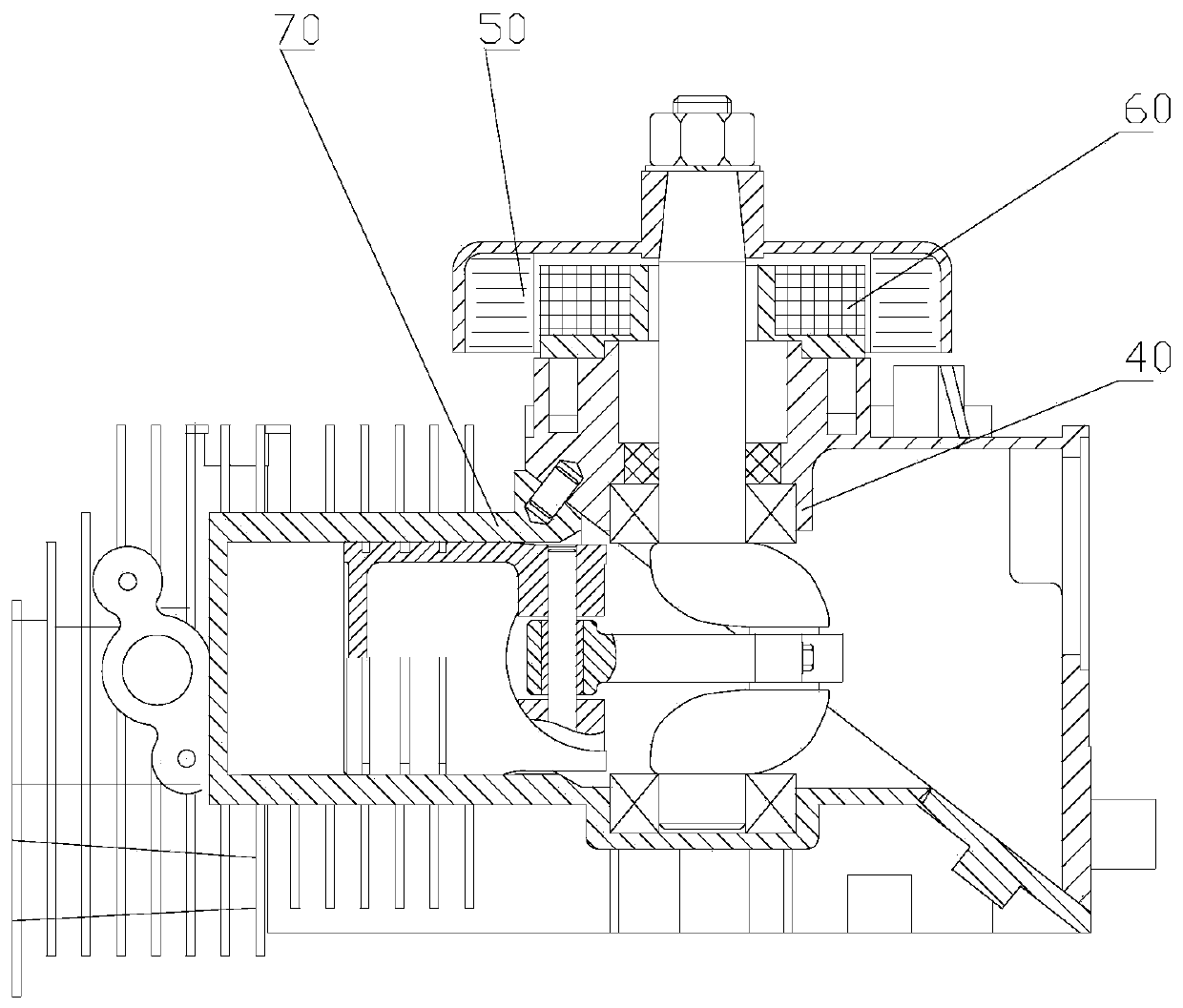

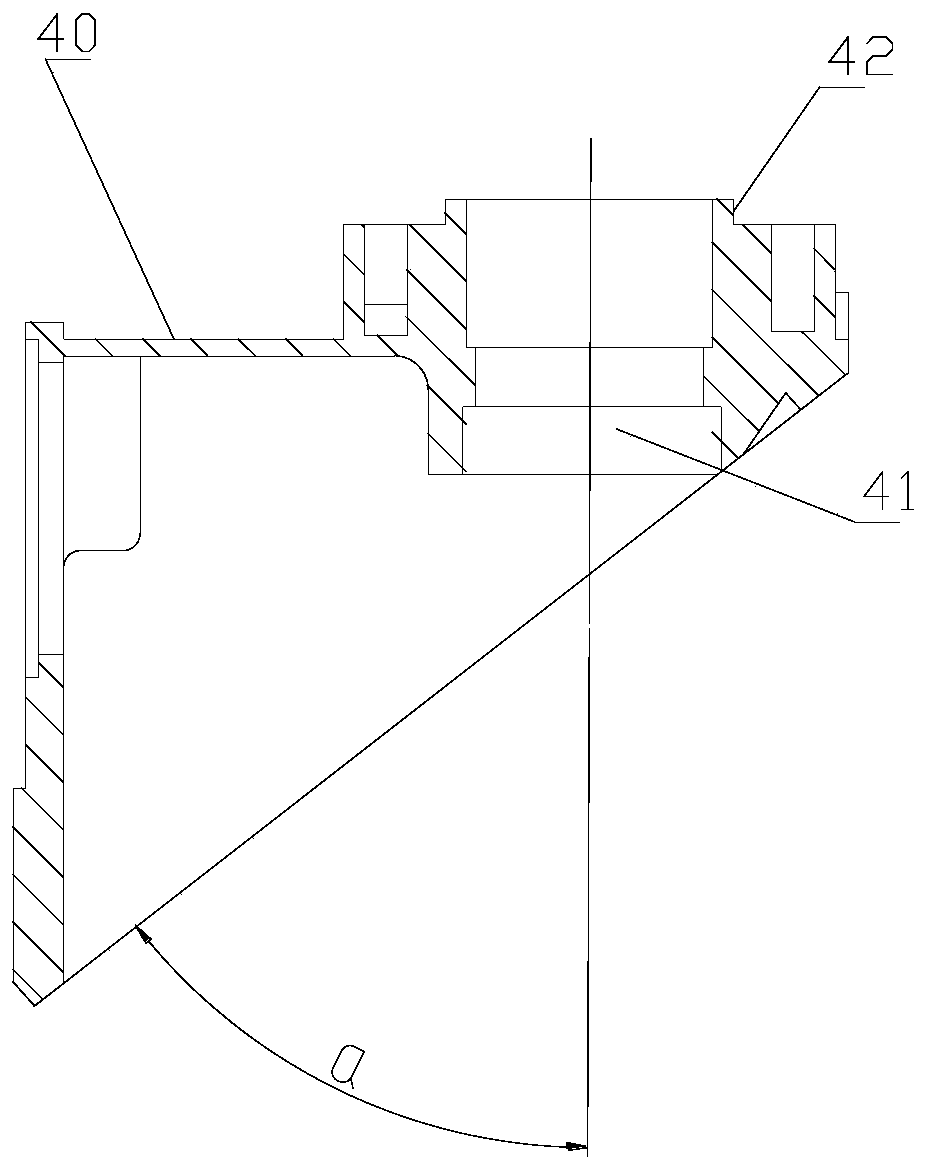

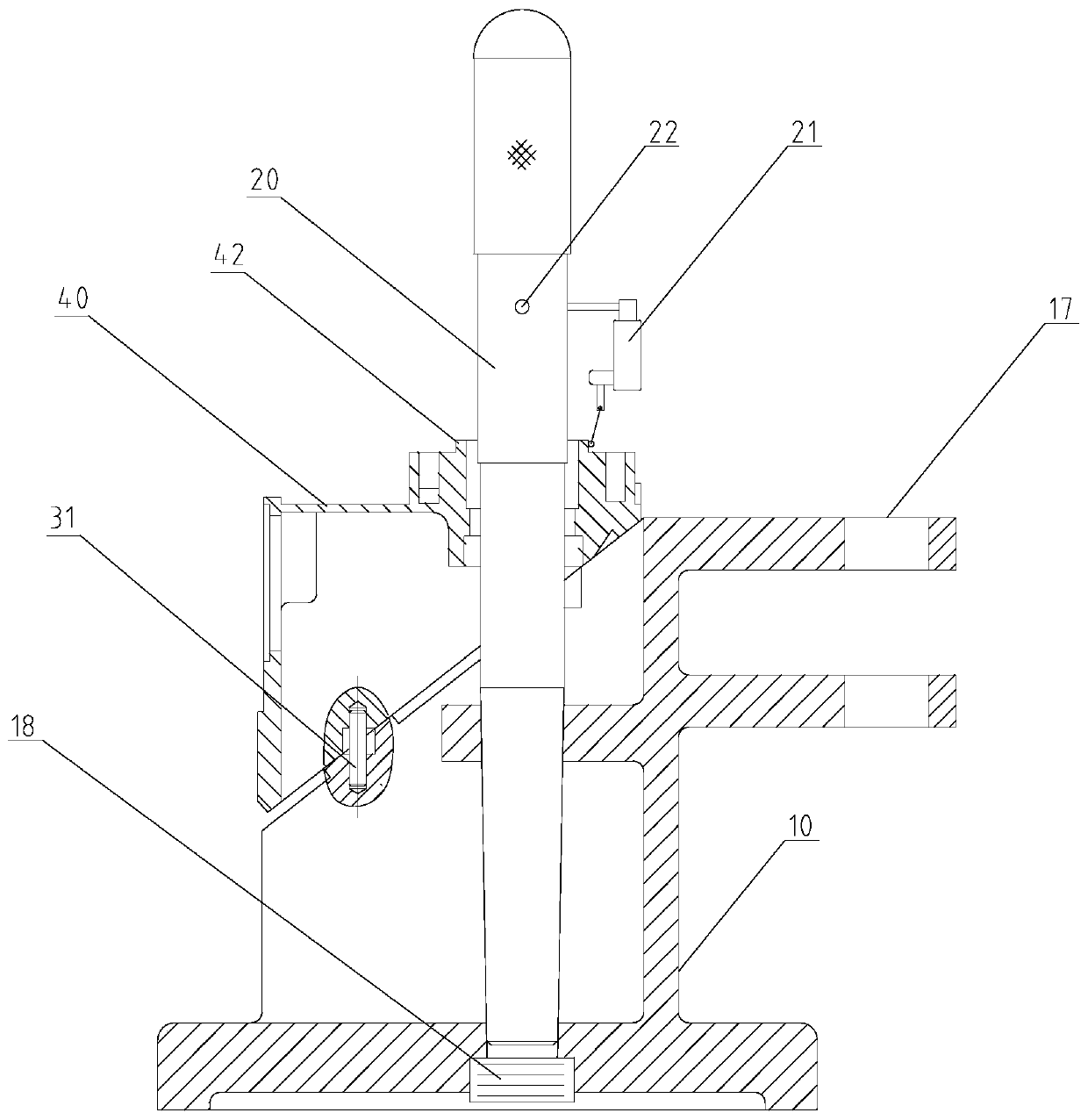

[0024] Such as Figure 3-5 As shown, the inspection tool for the wedge-shaped box cover of the generator set, the wedge-shaped box cover 40 of the generator set is provided with a bearing hole 41 and a stator positioning boss 42; the inspection tool includes a base 10 for coaxially passing through the The positioning shaft 20 and the fixing part 30 in the bearing hole 41 of the wedge-shaped case cover 40 of the generating set; the base 10 includes the mounting part 11; the fixing part 30 is used to fix the wedge-shaped case cover 40 of the generating set on the top of the mounting part 11 above; the positioning shaft 20 is used to be installed vertically on the mounting part 11 in a rotatable manner; the positioning shaft 20 is provided with a dial gauge 21, and the measuring head of the dial gauge 21 is used for aligning with the stator positioning pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com