Adjustment device for eliminating offset error of tiled grating

A technology for adjusting devices and gratings, which is applied in optics, optical components, instruments, etc., can solve the problems that there is no parallel monitoring of the grating surface, it is difficult to realize, and the cost is expensive, and achieves the effect of large error capture range, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

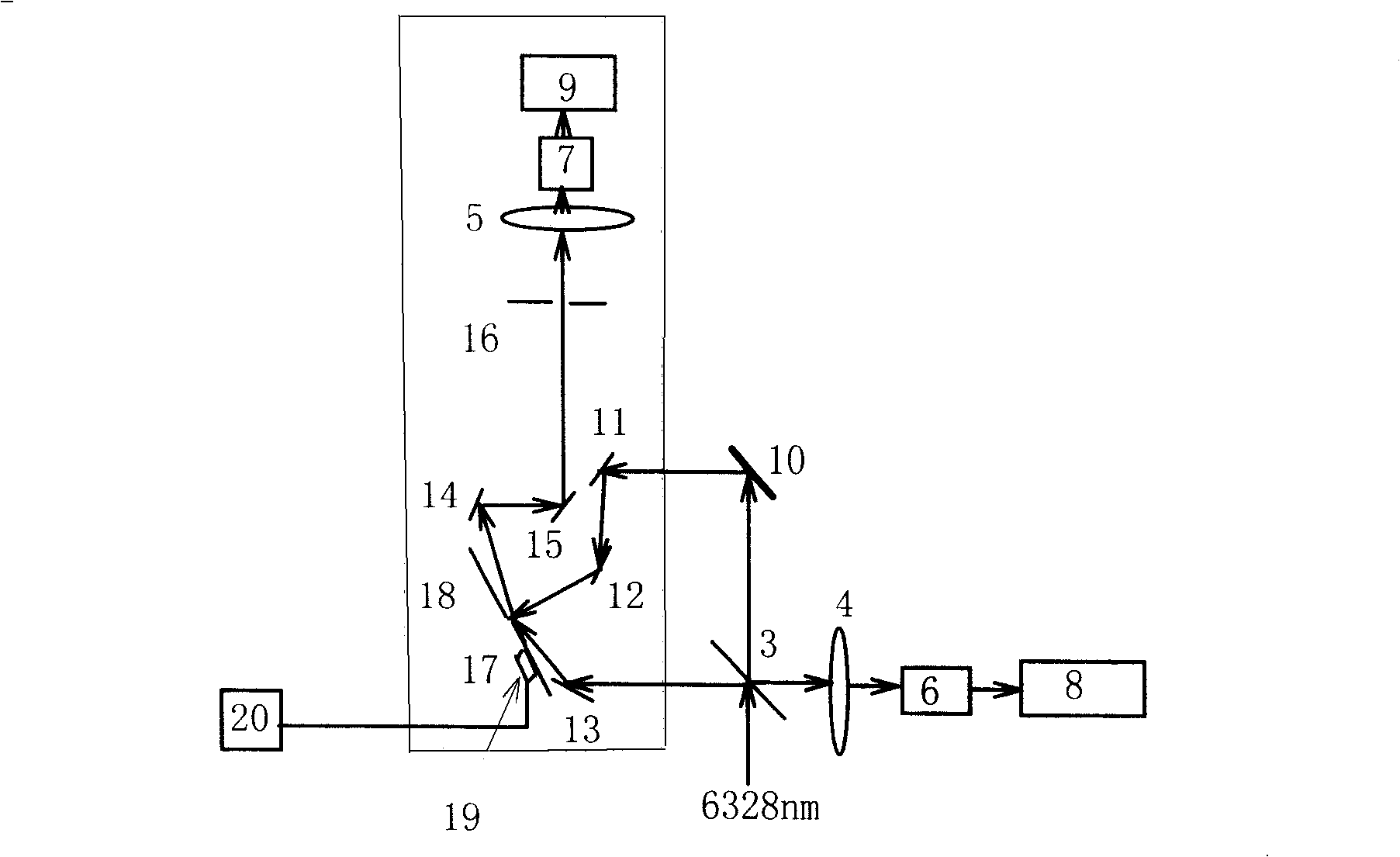

[0019] The adjustment device for eliminating dislocation errors of spliced gratings of the present invention includes a laser far-field monitoring part and a grating position adjustment part, and the dislocation error between spliced grating surfaces is eliminated by the grating position adjustment part by monitoring the change of the far-field shape of the laser pulse.

[0020] The implementation process of the invention is as follows: firstly, a laser far-field monitoring part is established, and then the grating is finely adjusted by the monitoring laser far-field and the grating position adjustment part. like figure 1 As shown, build the monitoring optical path. The transmitted part of the probe light incident on the beam splitter 3 is respectively reflected by the first plane mirror 10, the second plane mirror 11, and the third plane mirror 12, and then vertically incident on the first grating 17 and the second grating 18, and the reflection The light returns through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com