A kind of perforation drilling device and method in vertical drilling

An in-hole and vertical technology, applied in directional drilling, supporting devices, drilling equipment, etc., can solve the problems of complex technology, drilling without devices, and poor operability, so as to avoid complexity, facilitate storage, and facilitate adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

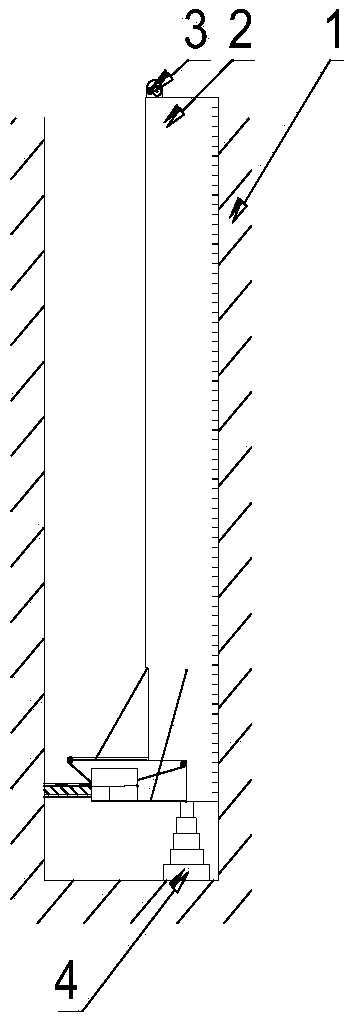

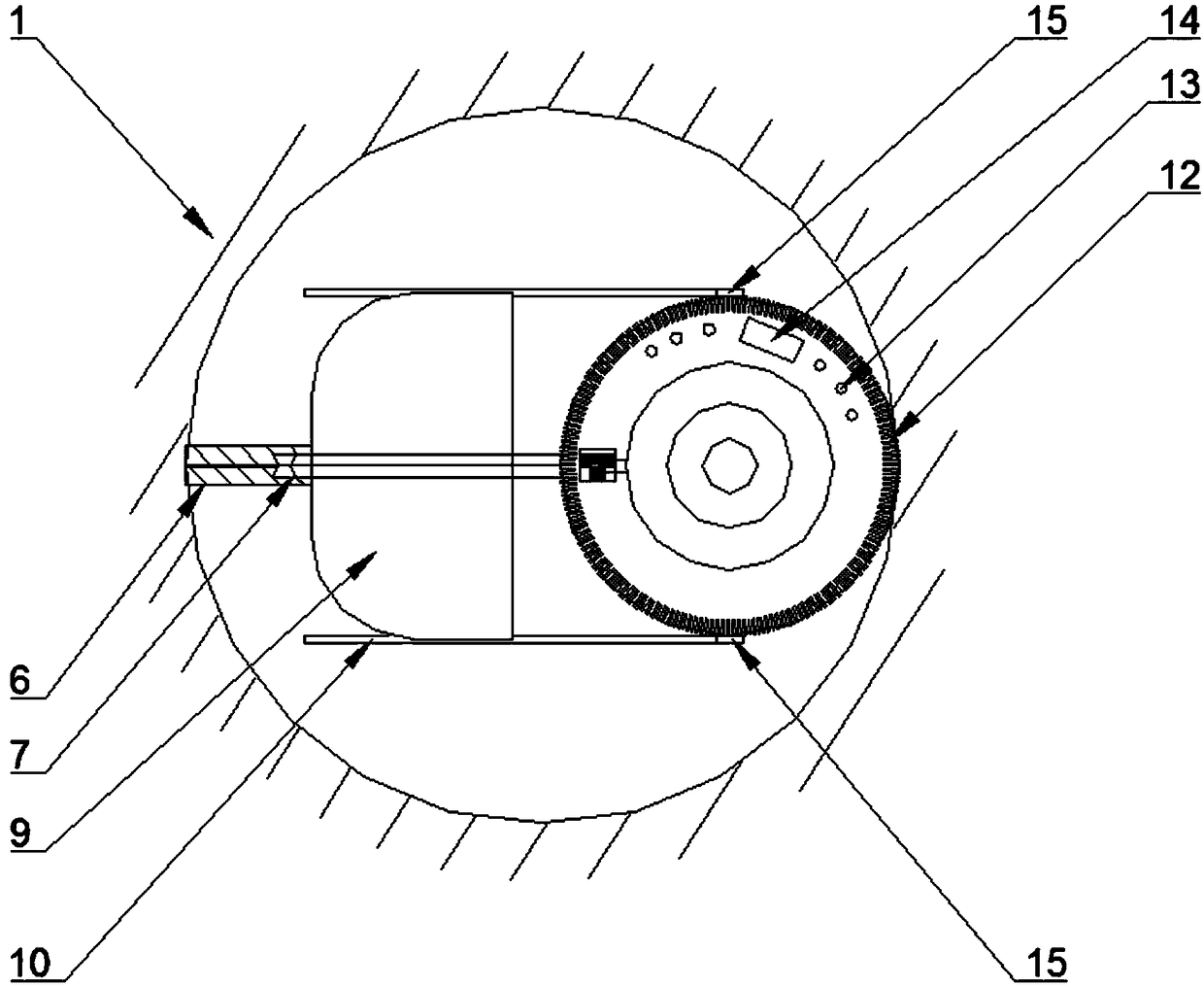

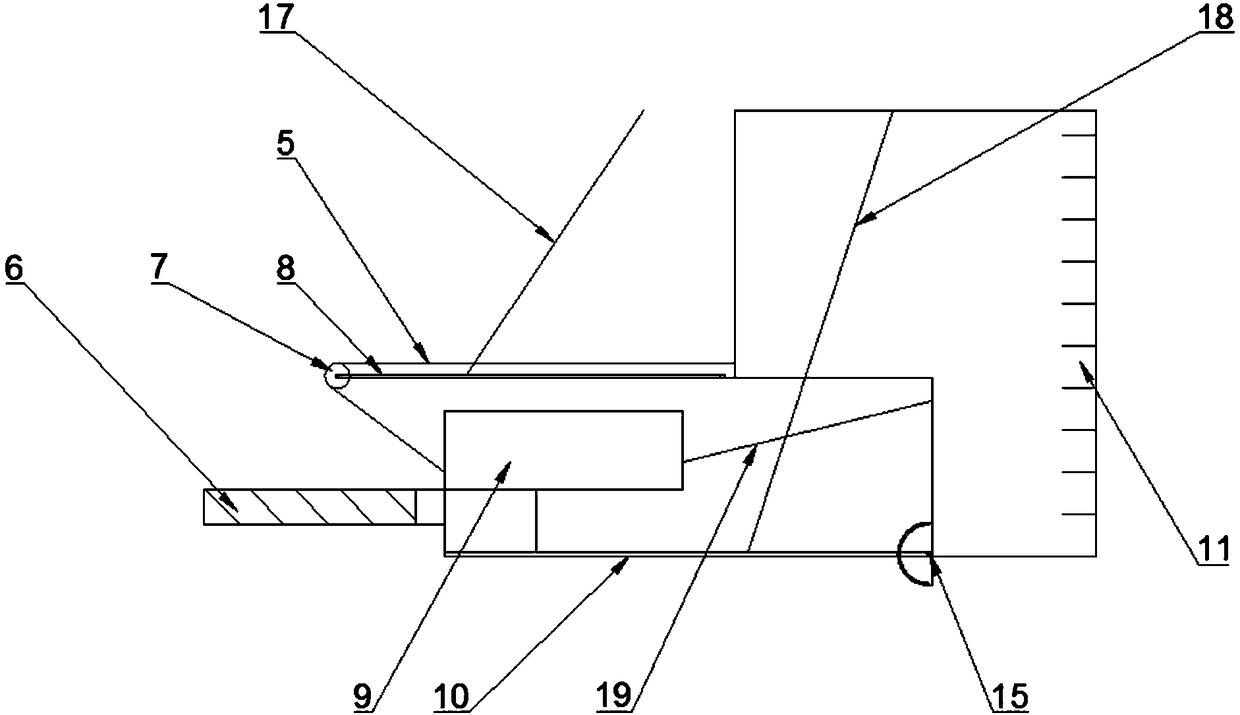

[0044]A perforation drilling device in a vertical borehole, comprising a metal hollow cylinder 2 that can be placed in a vertical borehole 1, a support member 4 is provided at the bottom of the hollow cylinder 2, an opening is opened on one side of the bottom of the hollow cylinder 2, and a A slideway 10 with one end hingedly connected to the bottom of the hollow tube 2 is provided inside, so that the slideway 10 can rotate up and down in the vertical plane of the opening. 10 sliding; one end of the drilling machine 9 drill bit is connected with the first wire rope 5 on the first hoist 3, and the first hoist rotates to drive the drilling machine 9 to advance on the slideway 10 through the first wire rope 5 to drill holes, and the other end of the drilling machine is connected to the second wire rope 5. The second wire rope on the hoist is connected, and the second hoist is rotated to drive the rig to retreat on the slideway through the second wire rope. A support cover can be ...

Embodiment 2

[0063] A perforation drilling device in a vertical borehole, comprising a hollow cylinder that can be placed in the vertical borehole, a support member is provided at the bottom of the hollow cylinder, an opening is opened on one side of the bottom of the hollow cylinder, and one end and a hollow cylinder are arranged in the opening. The slideway hingedly connected at the bottom of the cylinder, the drilling rig with the drill bit is set on the slideway and the drilling machine can slide along the slideway; one end of the drilling rig is connected or contacted with the propulsion mechanism at the bottom of the hollow cylinder, and the action of the propulsion mechanism drives the drilling rig to advance on the slideway Drilling is carried out, and the end of the drilling machine is connected with the second wire rope on the second hoist, and the second hoist is rotated to drive the drilling machine back on the slideway through the second wire rope.

[0064] The propulsion mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com