A method and device for in-situ volume reduction of dredged muddy water with high efficiency

A muddy water, in-situ technology, which is applied to the in-situ efficient volume reduction of dredged muddy water, realizes the field of in-situ efficient volume reduction of the dredged muddy water, and can solve the problem that the in-situ treatment of the dredging site cannot be realized, the equipment occupies a large area, and the dredging ships are implemented. Difficulty and other problems, to achieve the effect of rapid completion, small size and footprint, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

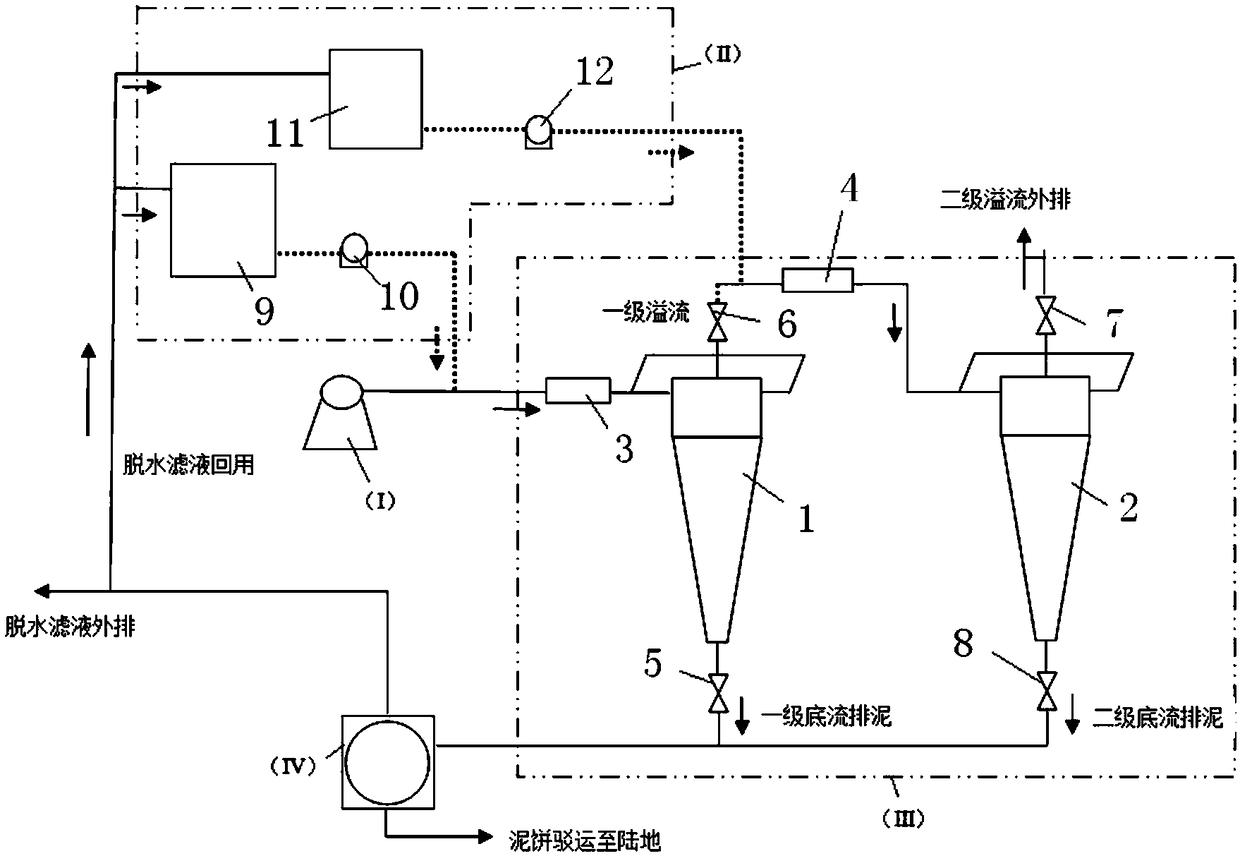

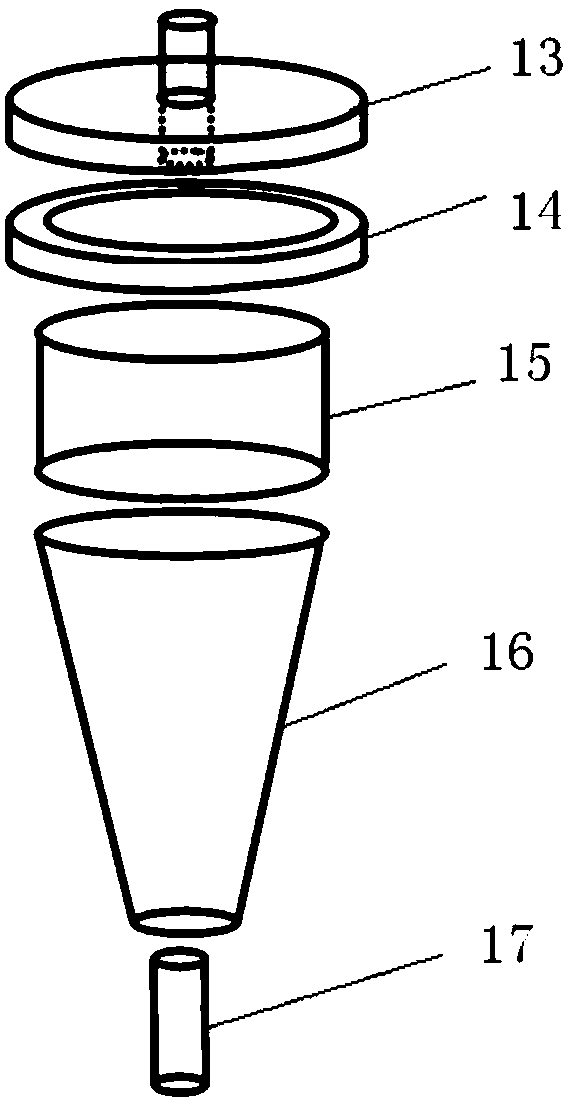

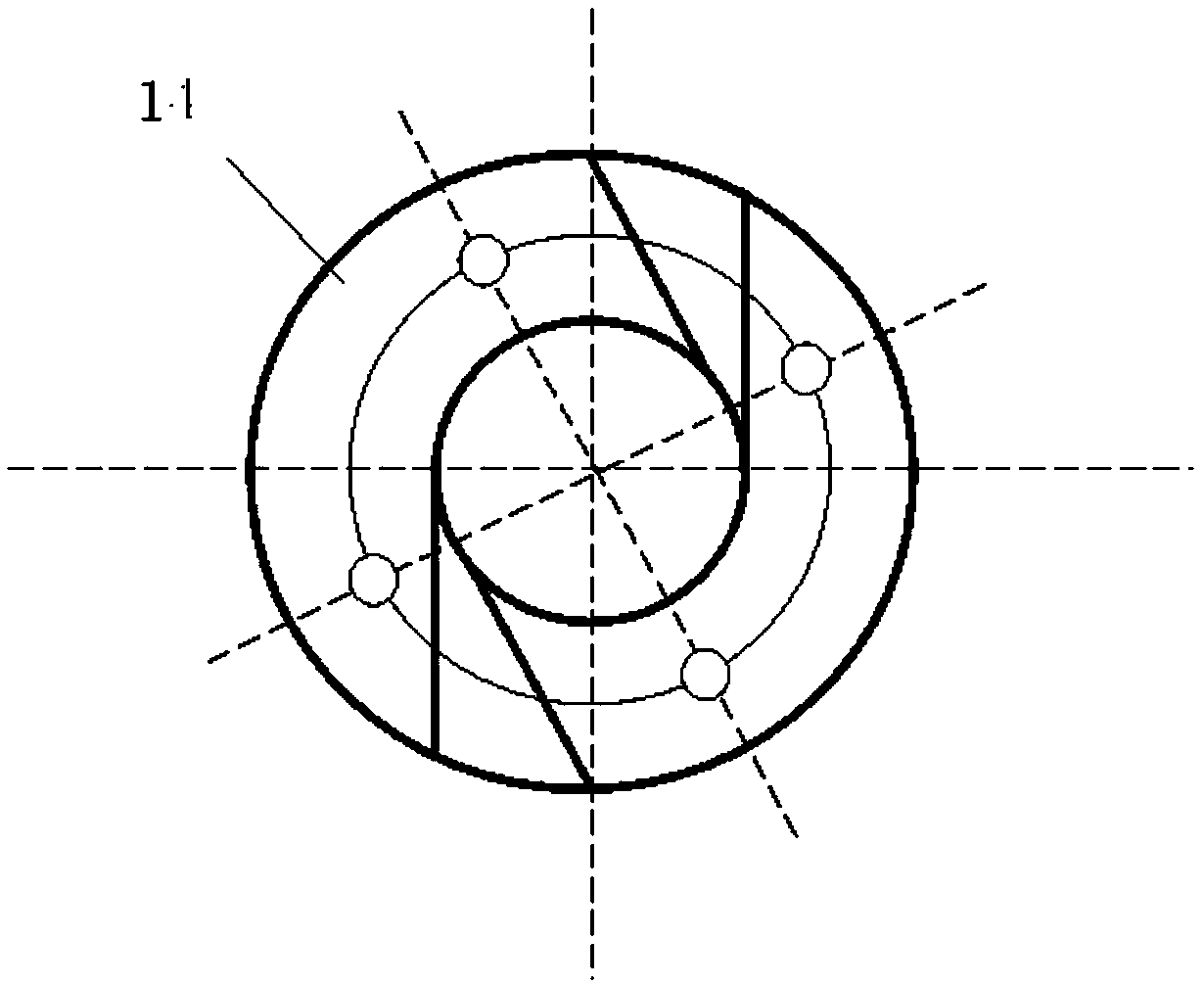

[0034] see figure 1 , figure 2 and image 3 , the method for in-situ efficient capacity reduction of dredged muddy water provided by the present invention, a two-stage series hydrocyclone system is set on the dredging ship, the centrifugal dehydrator is directly connected with the two-stage series hydrocyclone system, and the dredged muddy water sucked by the dredger ship and The coagulant from the coagulant mixing and dosing system is mixed and enters the two-stage hydrocyclone system for concentration and volume reduction treatment. The concentrated sludge after volume reduction is discharged into the centrifugal dehydrator for dehydration, and the overflow clear liquid is directly discharged into the water body.

[0035] Specifically, the dredged muddy water is pumped by the dredger pump I of the dredging ship. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com