Instrument board cross beam mounting component

A technology for installing components and instrument panels, applied in vehicle components, transportation and packaging, superstructure and other directions, which can solve the problems of difficult matching, insufficient rigidity of instrument panel beams, affecting users' use and perception, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

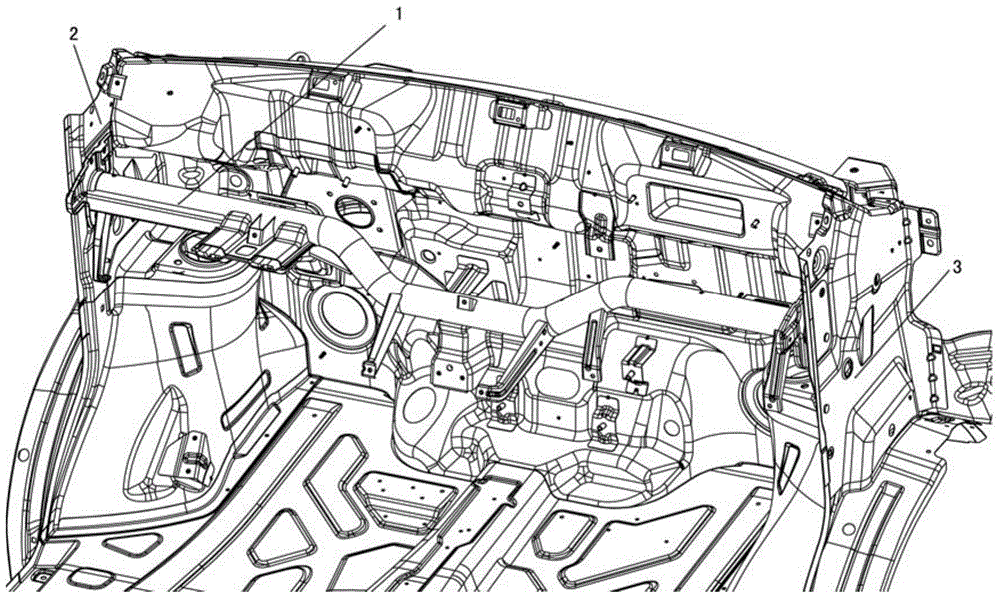

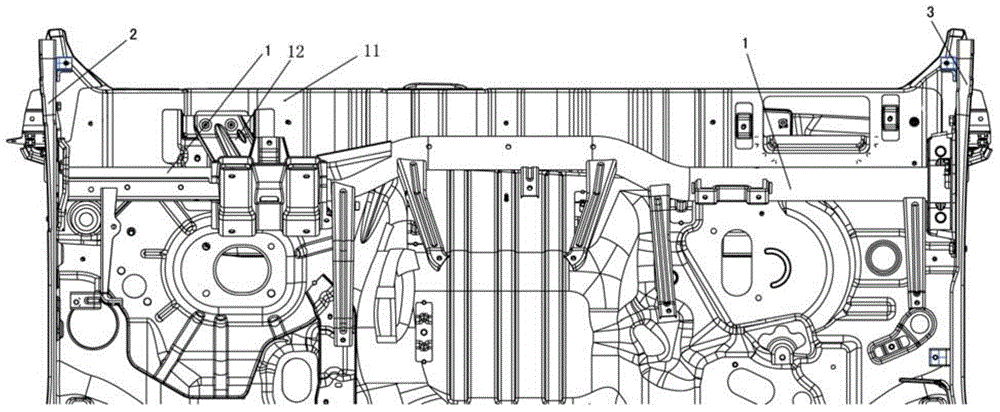

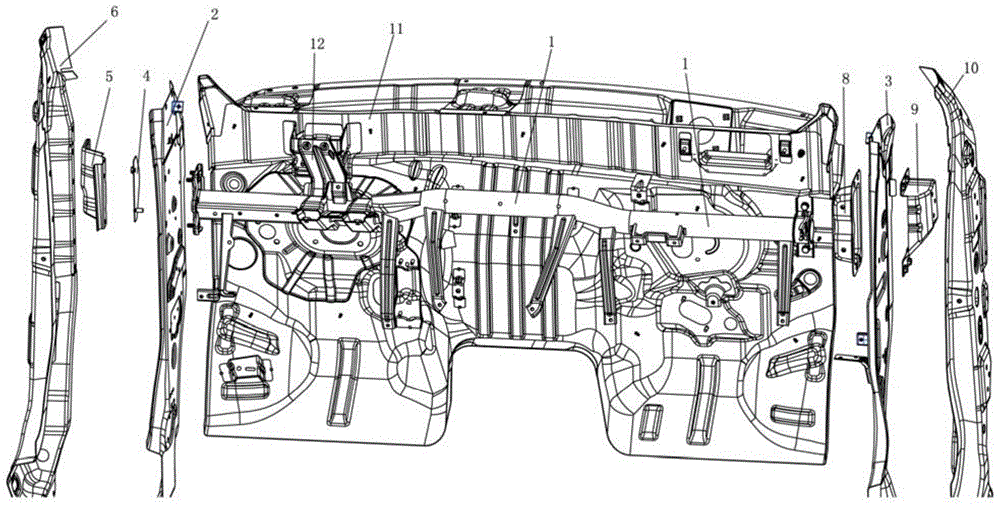

[0030] The following with attached Figure 2 to Figure 7 An instrument panel beam mounting assembly of the present invention is further described in detail.

[0031] An instrument panel beam installation assembly of the present invention, please refer to Figure 2 to Figure 7 , including a left mounting assembly for installing the instrument panel beam 1 on the left front side panel welding assembly 2 and a right mounting assembly for installing the instrument panel beam 1 on the right front side panel welding assembly 3, the left mounting assembly includes The reinforcement plate 4 and the Z-shaped reinforcement plate 5 are installed on the left side of the crossbeam, the reinforcement plate 4 is installed on the left side of the crossbeam, the welding assembly 2 of the left front side plate and the instrument panel beam 1 are fixed, and one side of the Z-type reinforcement plate 5 is connected to the The left front side panel welding assembly 2 and the instrument panel beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com