Special fixture for boring hole groups in bearing blocks of drum-shaped box bodies

A special fixture and bearing seat hole technology, applied in the field of machining fixtures, can solve the problems of box positioning, clamping, adjustment, processing difficulties, low processing efficiency of seat hole groups, etc., to achieve convenient operation, compact clamping, high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be construed as a limitation on the technical solution, and improvements on this basis all belong to the protection category of the present invention.

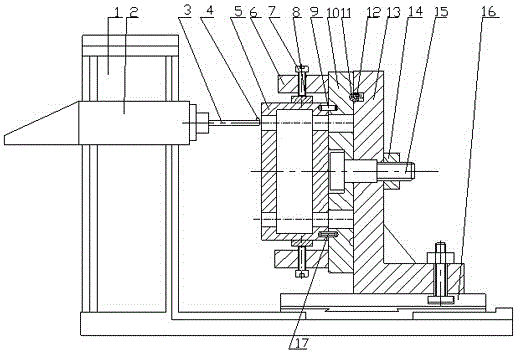

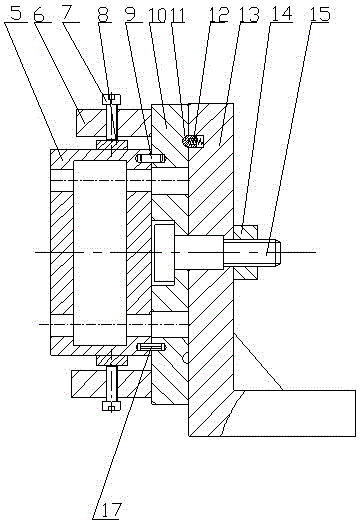

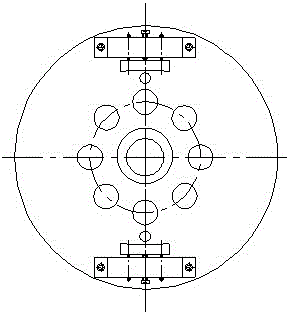

[0020] Such as Figure 1-5 As shown, the boring special fixture includes a fixture seat 13, a fixture body 10 and a clamping body; a positioning hole is set on the left end surface of the fixture seat 13, and a No. 2 cylindrical pin 11 and a No. 1 spring 12 are installed in the positioning hole; 10 is disc-shaped, and there are several hemispherical positioning holes evenly distributed on the circumference on its right end surface and several through holes with a slightly larger hole size corresponding to the bearing seat hole of the drum-shaped box body. The No. 1 cylindrical pin 9 and rhombic pin 17 are distributed on the left end surface; the clamping body is composed of a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com