Embedded type thermal resistor for motor of nuclear power station

An embedded, nuclear power plant technology, applied in the direction of electromechanical devices, electrical devices, circuits, etc., can solve the problems of increasing the use cost of the motor, reducing the work efficiency of the operator, and being unable to replace it, so as to prolong the service life and improve the overall torsional strength. , fixed firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

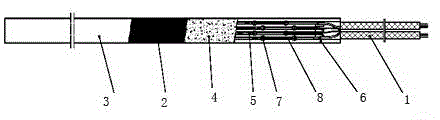

[0012] An embedded thermal resistor for a nuclear power plant motor, comprising a cable 1 and a copper foil 2, the cable 1 is located inside the copper foil 2, an adhesive tape 3 is provided outside the copper foil 2, and an adhesive tape 3 is provided between the copper foil 2 and the cable 1 There is a rubber 4, the inner side of the rubber 4 is provided with a temperature sensing element 5, the cable 1 is wrapped with a rubber plate 6, the temperature sensing element 5 is provided with a solder joint copper sheet 7, and the two sides of the solder joint copper sheet 7 are provided with bridge wires 8 , the middle of the bridge wire 8 is equipped with a solder joint copper sheet, the tape 3 is located on the outer surface of the copper foil, the tape 3 wraps the cable, the cable 1 is a double-core cable, and the cable 1 is provided with a protective layer to protect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com