Novel rotary vertical wire clamp

A rotary, vertical line technology, applied in electrical components and other directions, can solve the problems of reducing the service life of the clip, insufficient strength, corrosion, etc., and achieve the effect of improving the external strength, ensuring the use effect, and expanding the use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

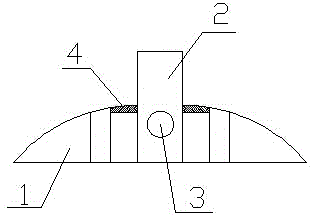

[0012] A new type of rotary vertical line clamp, which is provided with a hull 1 and a hanger 2, the hull 1 and the hanger 2 are connected to each other, the hanger 2 is connected to the hull 1 through a rotating shaft 3, the hull 1 is a mutual symmetrical structure, and the hull 1 is Left and right hollow structures, the middle of the hull 1 is provided with a cable slot, the cable slot is a semicircular structure, the rotary shaft 3 passes through the hanger and the hull, the hanger 2 is provided with a connecting hole, and the connecting hole is located at the top of the hanger 2, A cushion is arranged in the connecting hole, and the cushion is located on the inner side of the connecting hole. The cushion is a flexible cushion, and a rotary shaft 3 is correspondingly arranged under the connecting hole. , the hull 1 is provided with a bead 4, which is located between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com