Flexible oled substrate structure and design method

A flexible substrate and substrate technology, which is applied in the directions of organic semiconductor devices, electric solid-state devices, semiconductor devices, etc., can solve the problem of difficult to meet the bending design of flexible OLED substrates, and achieves improved rollability, reduced bending radius, and increased rollability. effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

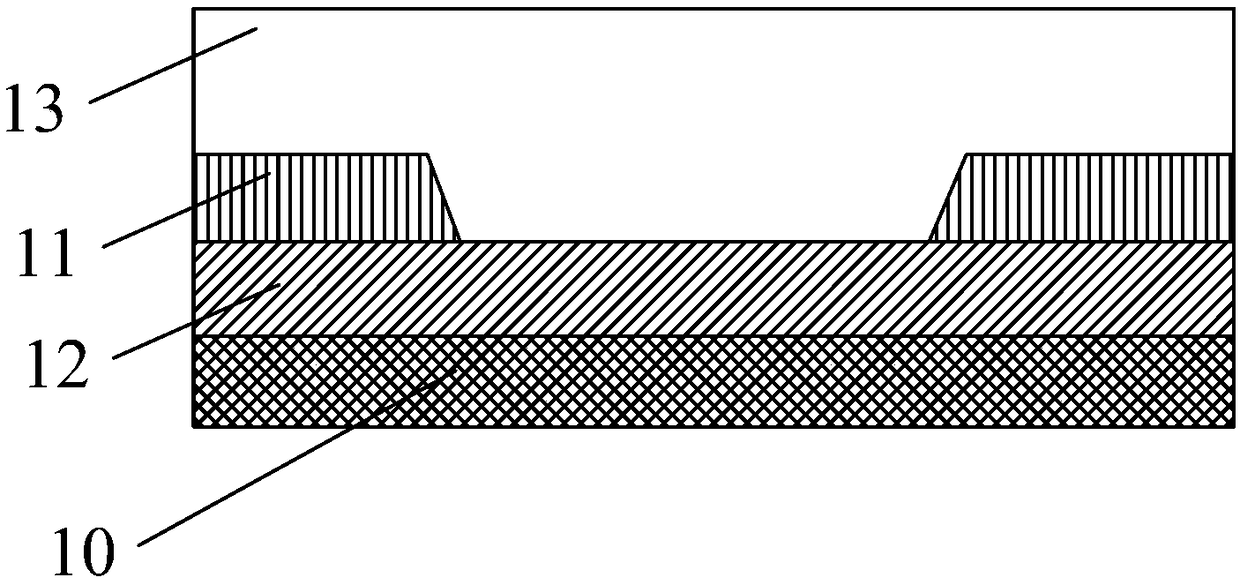

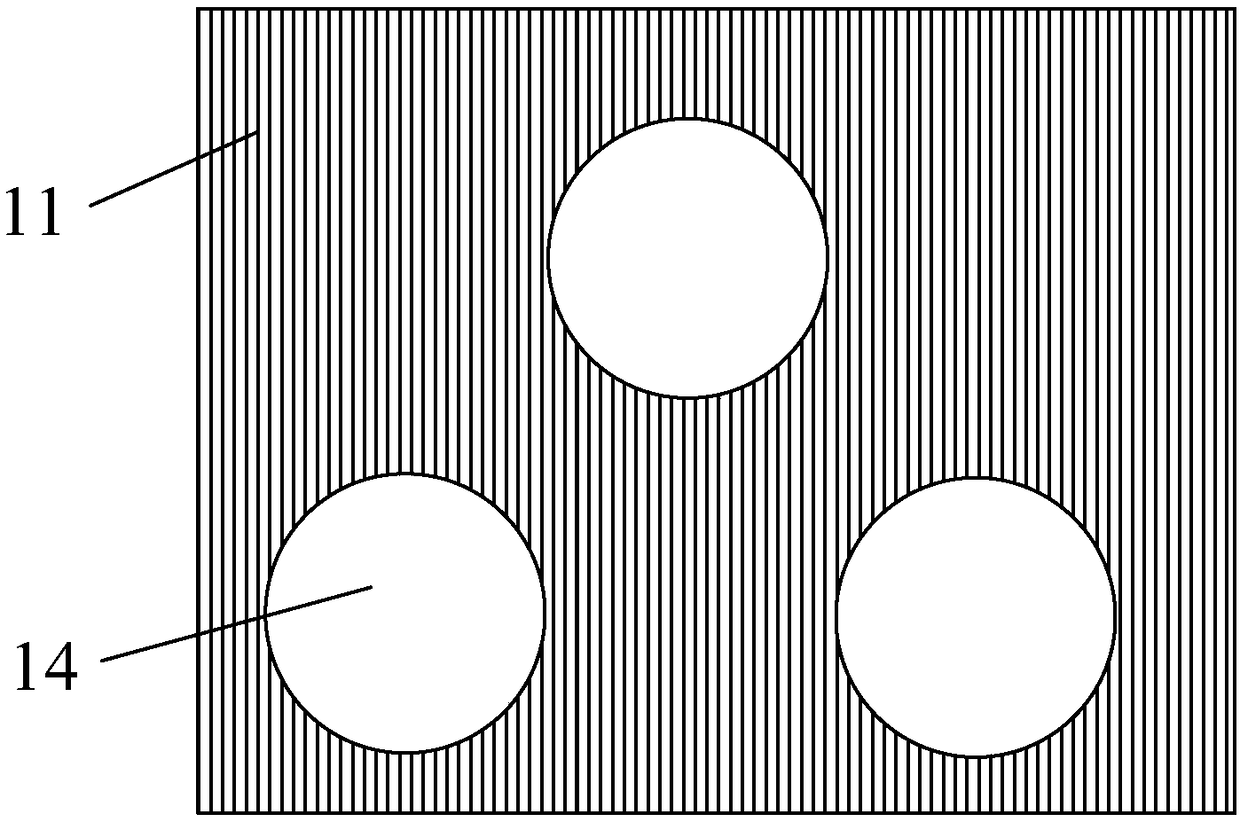

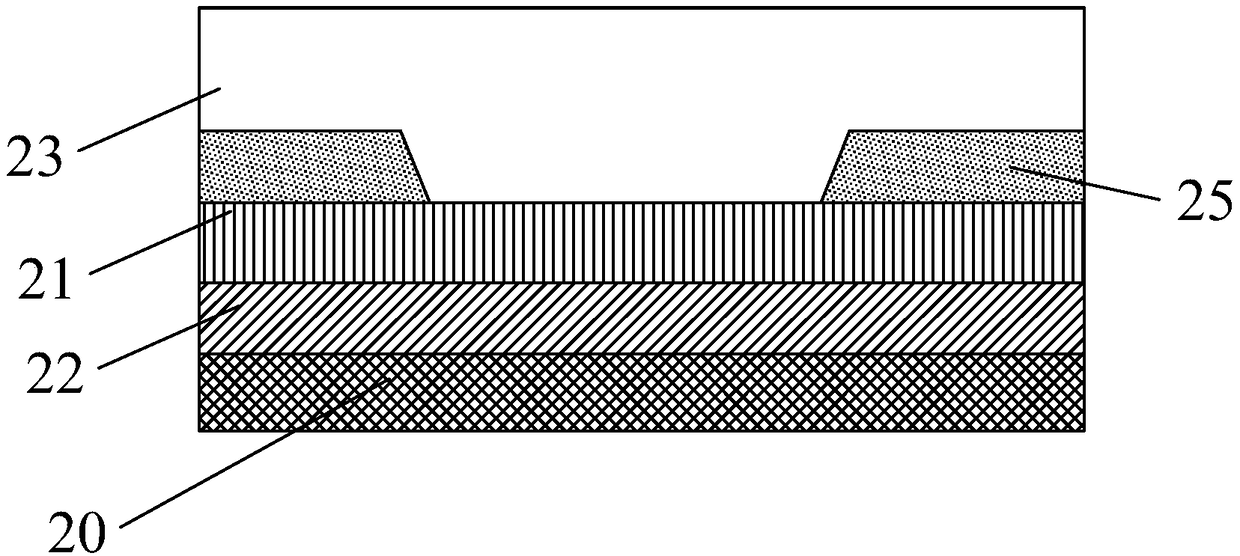

[0029] see figure 1 and figure 2 , figure 1 It is a schematic cross-sectional view of the first preferred embodiment of the flexible OLED substrate structure of the present invention, figure 2 for figure 1 A schematic top view of the first inorganic layer in . The flexible OLED substrate structure mainly includes a flexible substrate 10, a first inorganic layer 11, a second inorganic layer 12, and an organic layer 13. The second inorganic layer 12 is disposed on the flexible substrate 10, and the first inorganic layer 11 is disposed on the flexible substrate. On the second inorganic layer 12 , the organic layer 13 is disposed on the first inorganic layer 11 . The flexible substrate 10 may be a polyimide (PI) substrate. A plurality of via holes 14 are provided on the first inorganic layer 11 where conduction is required to conduct conduction and adjust the pattern density of the inorganic layer. In this embodiment, the via holes 14 are circular, and the ratio of the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com