A high-efficiency hot blast stove device

A hot blast stove, high-efficiency technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low energy utilization rate, low fuel utilization rate, waste of resources, etc., and achieve convenient cleaning and fuel utilization. The effect of high efficiency and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

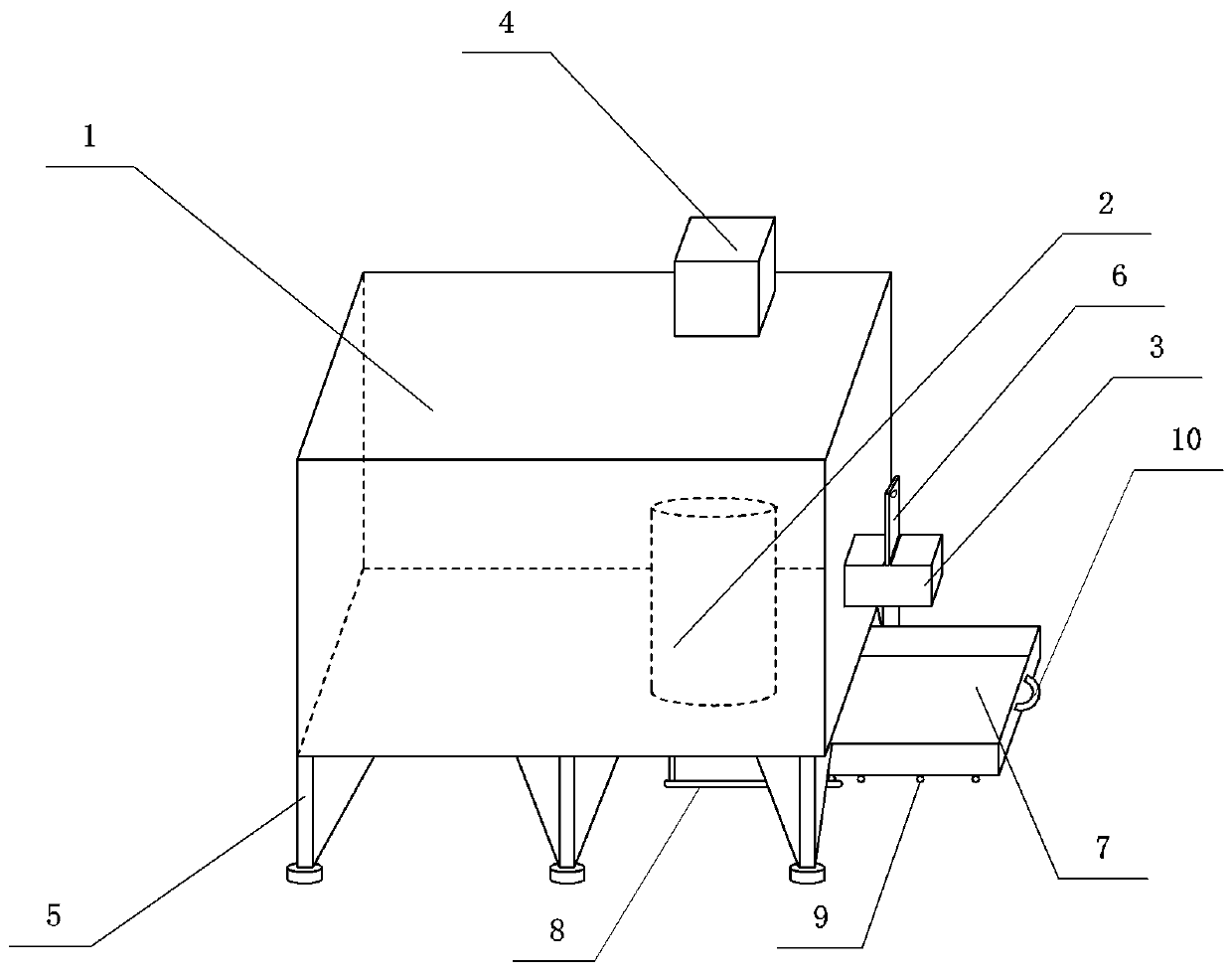

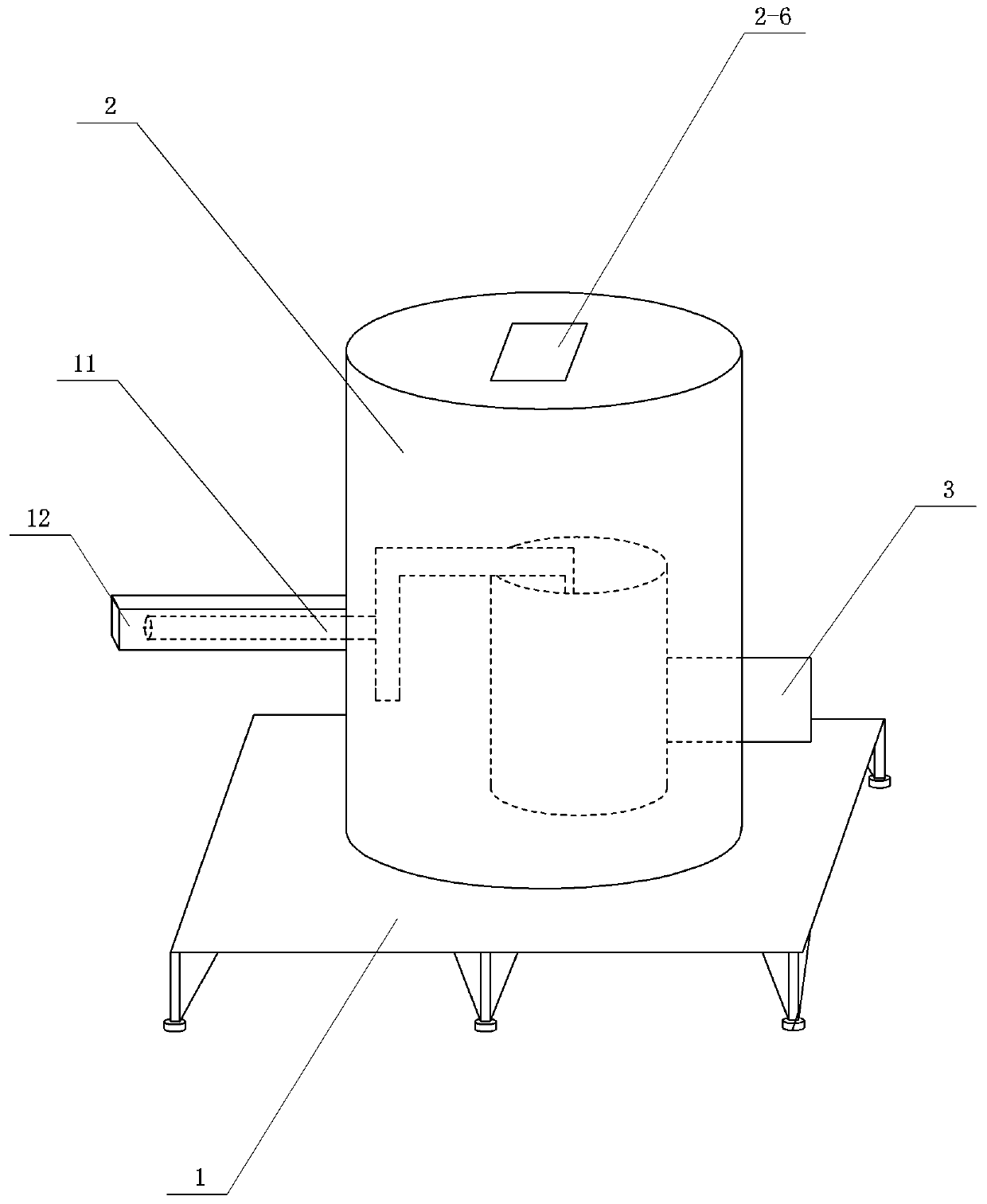

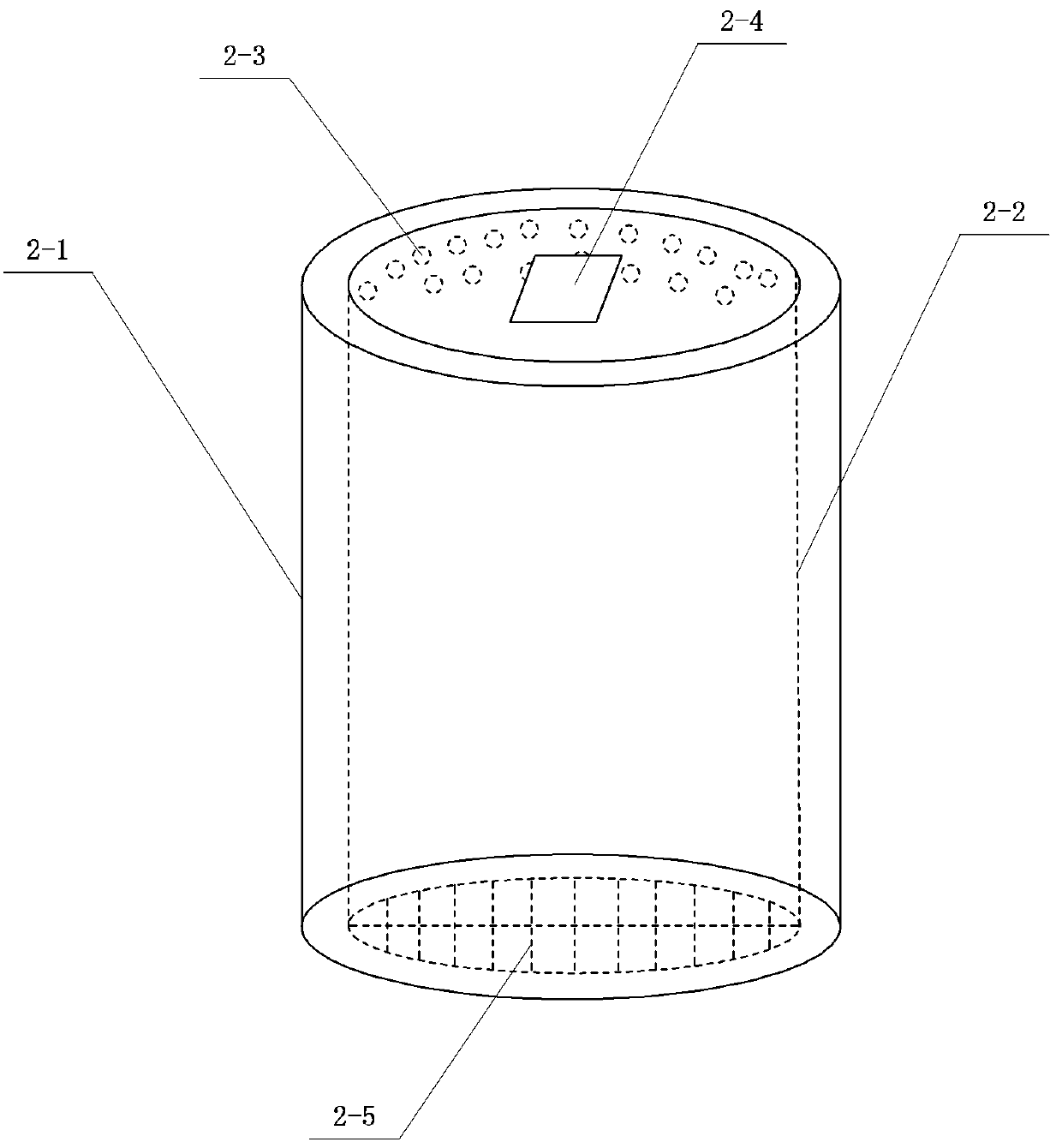

[0017] Embodiment 1: high-efficiency hot blast stove device, see figure 1 , figure 2 and image 3 , including a shell 1 and a furnace body 2, the bottom of the shell is provided with a support 5, in order to increase the support strength, the support is designed as a number of equidistantly arranged triangular support frames, and a disc type support is installed at the bottom of the triangular support frame seat. The furnace body 2 is installed in the shell, and a composite stainless steel liner is installed in the furnace body 2, such as image 3 As shown, the composite stainless steel liner has a double-layer structure, which is divided into an inner liner body 2-2 and an outer liner body 2-1. The inner liner body and the outer liner body are respectively made of high-temperature resistant stainless steel 310#, which replaces the traditional refractory brick material , The design of the composite double-layer liner improves the service life of the hot blast stove

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com