A drum brake automatic cooling system

A drum brake, automatic cooling technology, applied in the direction of brake type, brake components, slack adjuster, etc., can solve the problems of poor heat dissipation, closed brake structure, brake temperature rise, etc., to improve driving safety, reduce manual participation, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

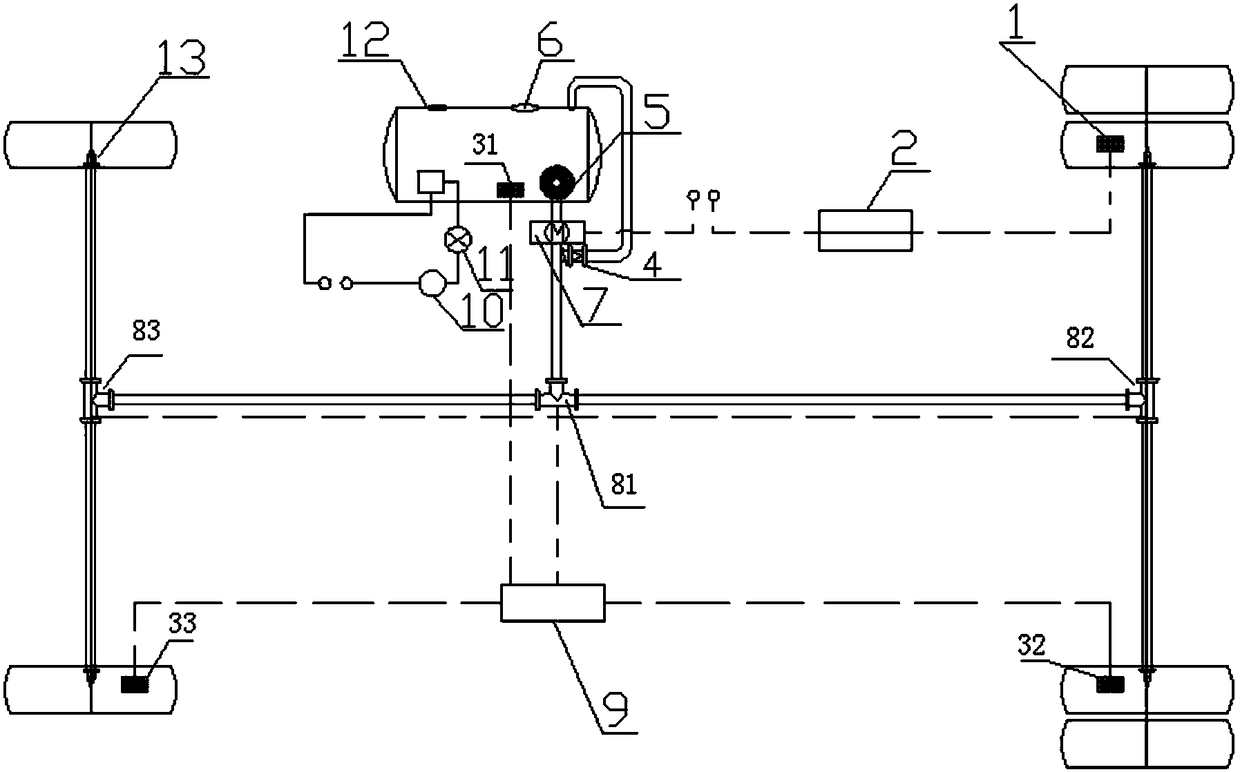

[0031] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0032] Such as figure 1 , figure 2 As shown, a drum brake automatic cooling system, including:

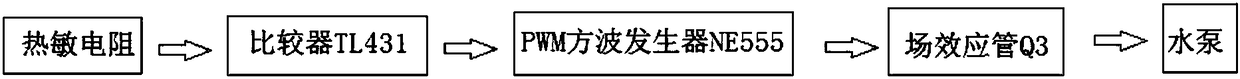

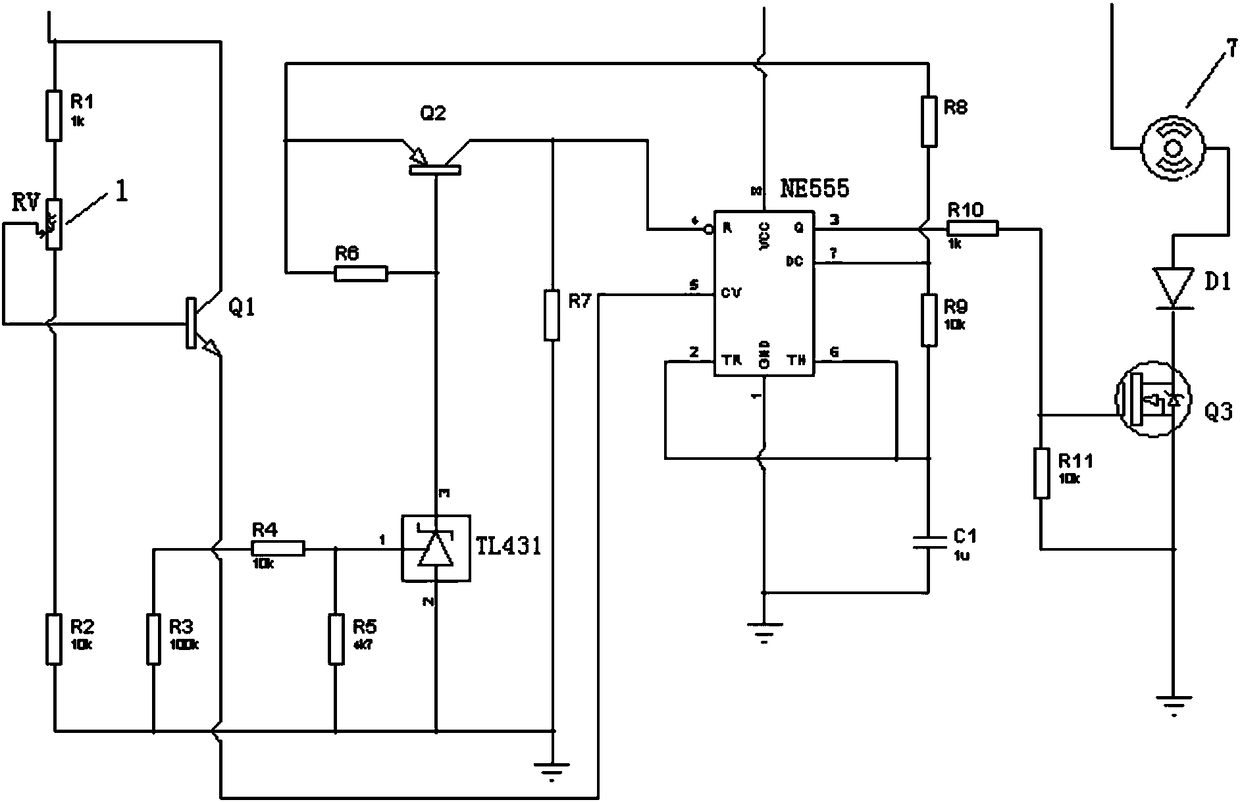

[0033] Thermistor 1 is used to detect the temperature of the brake pads in the brake and is installed on the brake pads of the brake;

[0034] Comparator TL431, when the temperature of the thermistor RV is higher than the preset value, the comparator TL431 is turned on; when the temperature of the thermistor RV is lower than the preset value, the comparator TL431 is turned off;

[0035] PWM square wave generator NE555: The conduction signal output by the comparator TL431 triggers the PWM square wave generator NE555 to work, and outputs a square wave signal;

[0036] Field effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com