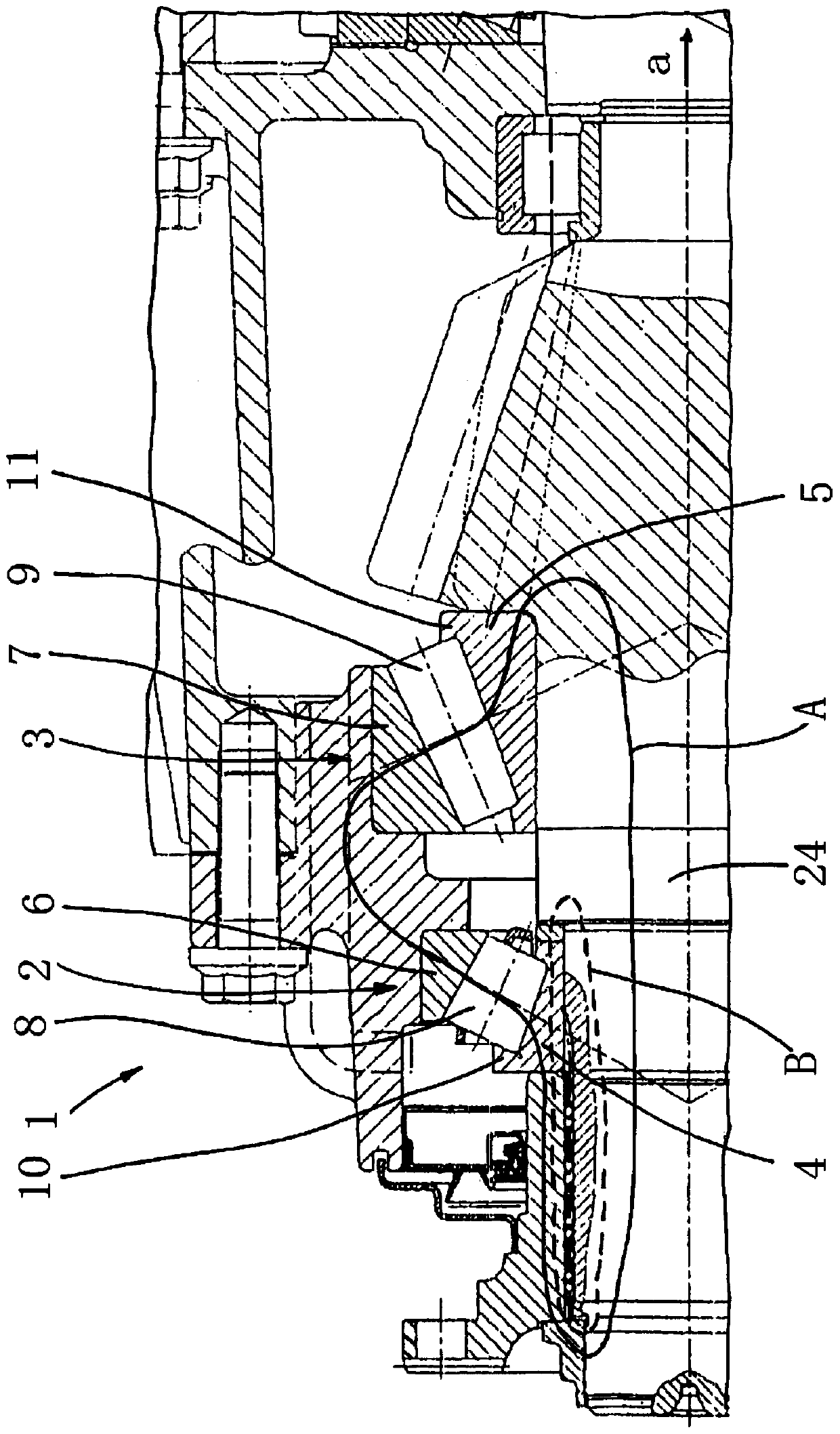

Bearing combination unit

A combination unit and bearing technology, applied in the direction of bearing assembly, bearing components, bearings, etc., can solve problems such as difficult adjustments and imperfect solutions, and achieve the effect of simple adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

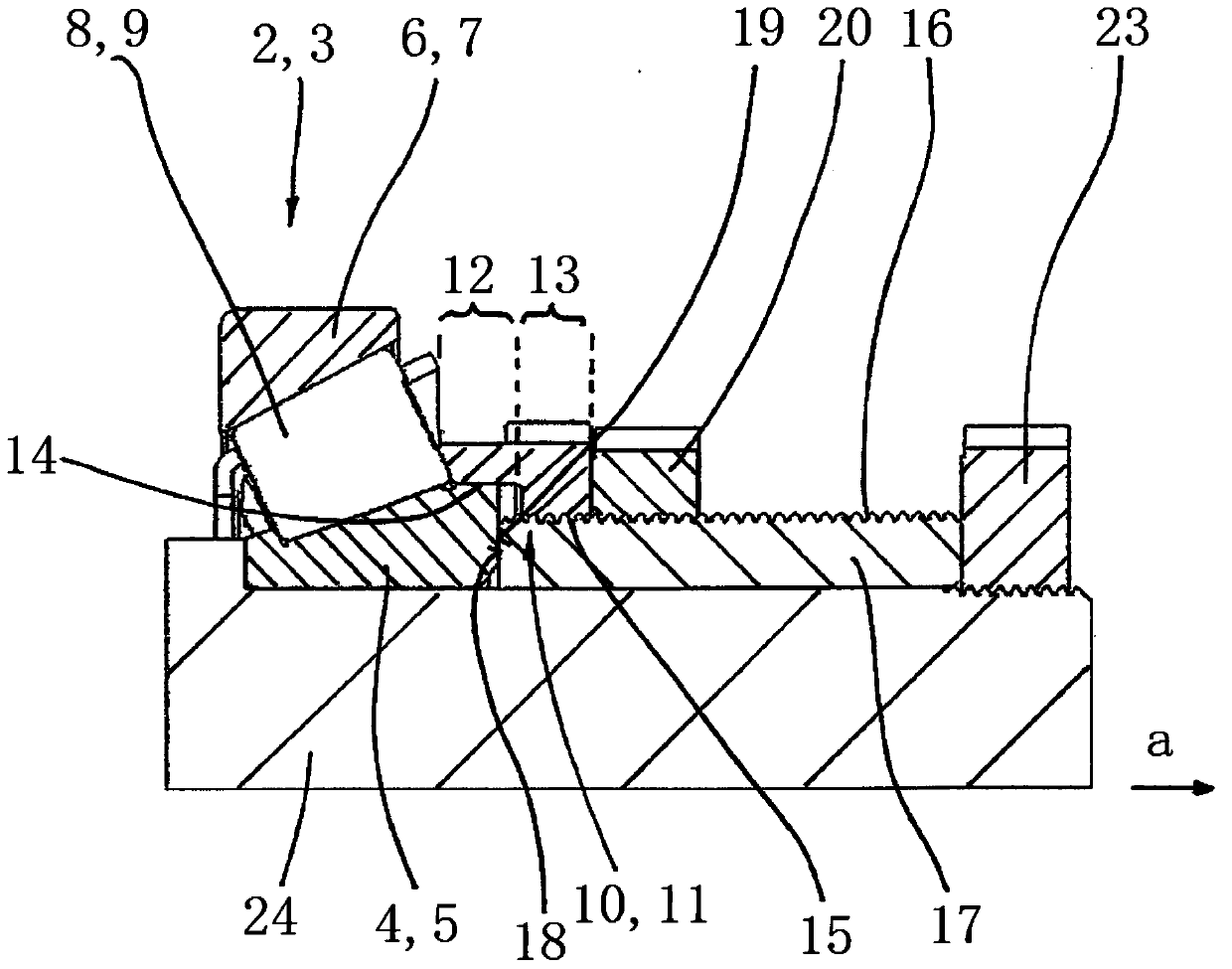

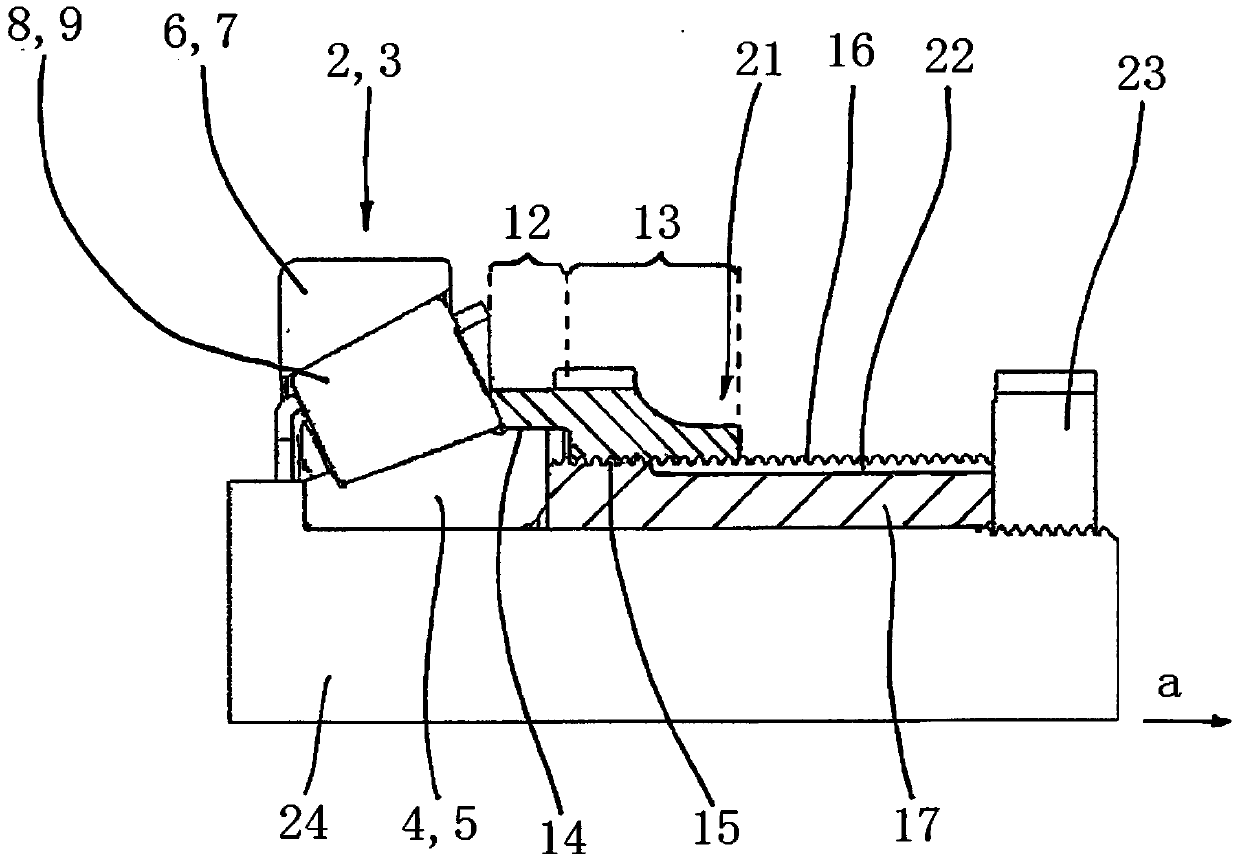

specific Embodiment approach

[0066] The force that needs to be introduced via the adjustable ribs 10 , 11 in order to obtain the desired pretensioning of the rolling elements is generally about an order of magnitude smaller than the force required for pretensioning the inner rings 4 , 5 . This allows the invention to adopt a specific embodiment: especially in large bearing units, for example, the ribs 10, 11 provided with the thread 15 can be axially adjusted according to the operating state by means of a servomotor (then of course without the aid of a device 20, 21), so that there is always an optimum preload in the bearing unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com