A bucket mechanism of telescopic arm type grid decontamination machine

A technology of telescopic arm and decontamination machine, which is applied in the direction of earth mover/shovel, water conservancy project, artificial waterway, etc. effect, good unloading effect, and the effect of reducing the load of the rake bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The following examples are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

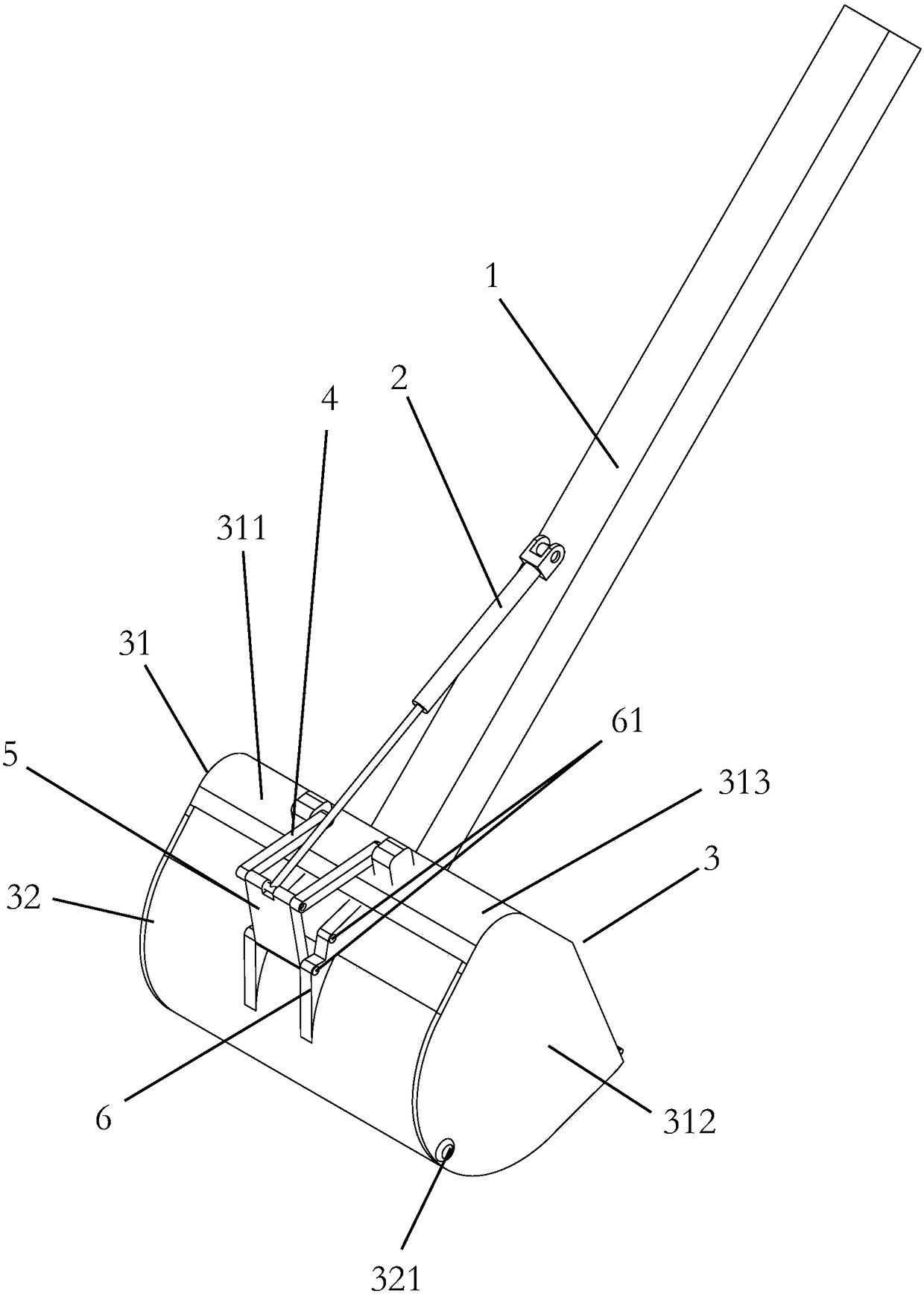

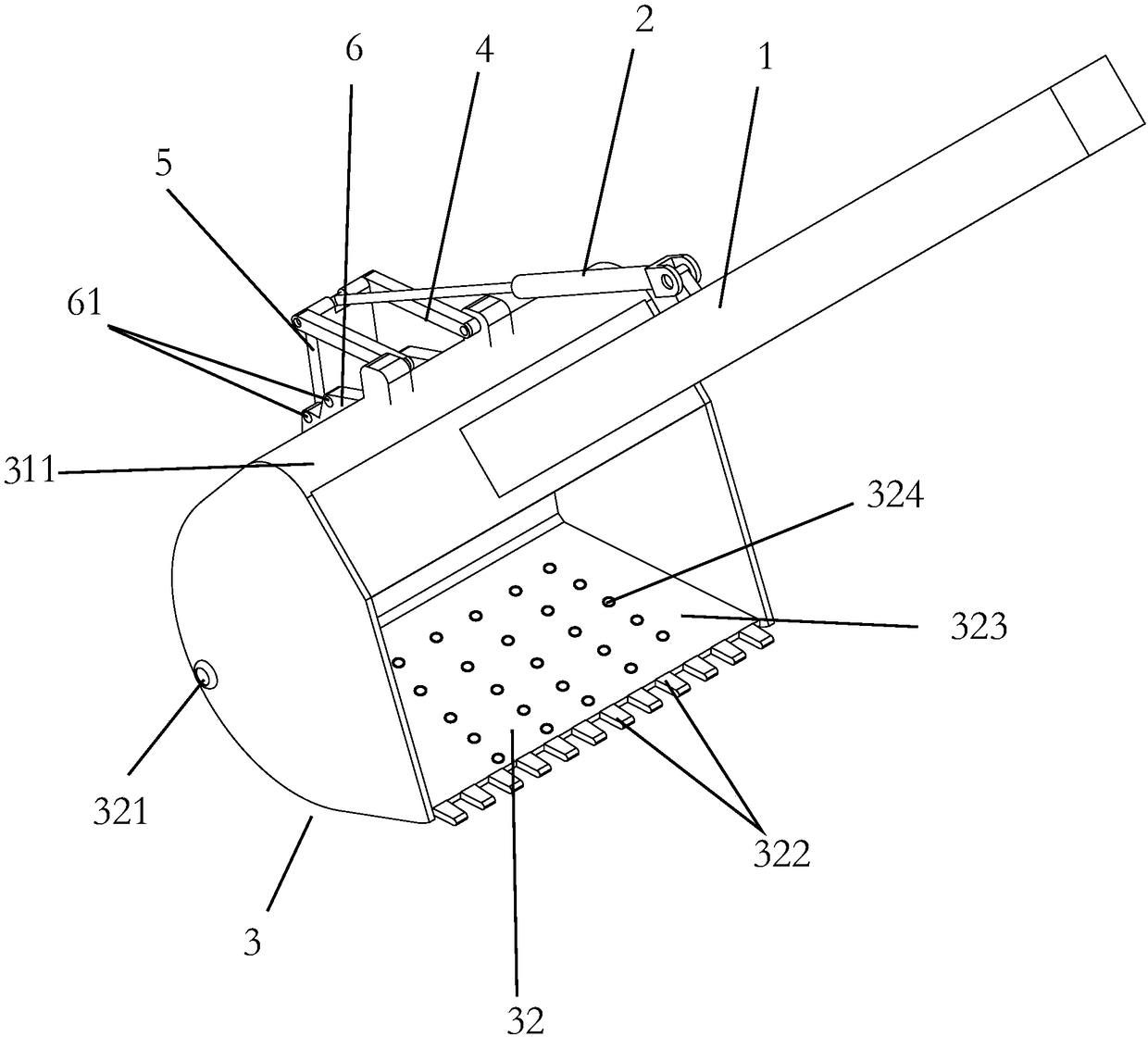

[0024] A bucket mechanism of a telescopic arm type grid decontamination machine, including a hydraulic telescopic arm 1, a hydraulic cylinder 2, and a bucket 3. The bucket 3 includes a bucket body 31, a bucket flap 32, and the bucket flips The plate 32 is composed of an inwardly bent upper flap 313 connected to a flat shovel-shaped lower flap 323 at the bottom. The bucket body 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com