Alcohol-solvent-resistant, wear-resistant and yellowing-resistant surface polyurethane resin and preparation method thereof

A polyurethane resin, anti-yellowing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of alcohol wipe resistance and poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

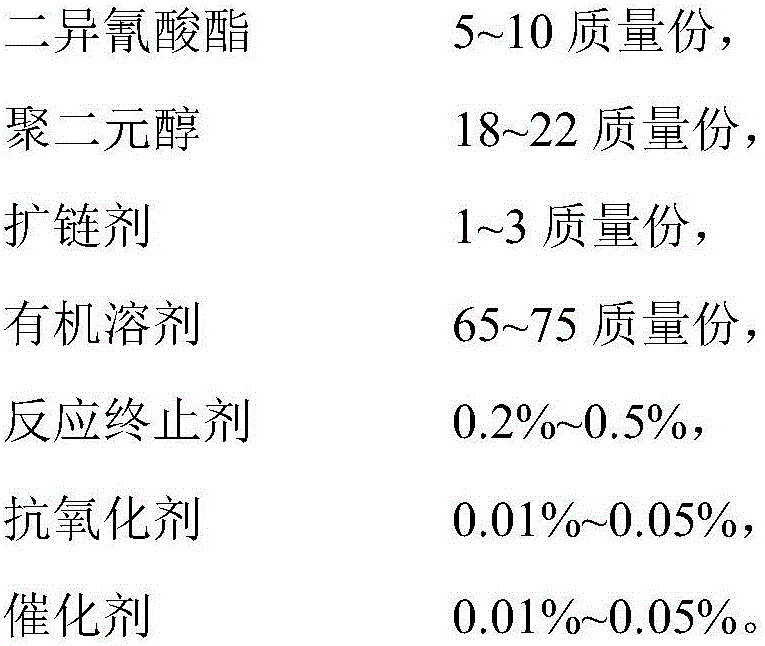

Method used

Image

Examples

Embodiment 1

[0042] 1. Raw material and ratio:

[0043]

[0044] 2. Preparation

[0045] (1) earlier the PC-2 of 110kg, the PTMG-2 of 25kg, the EG of 1kg, 0.3kg antioxidant I-1010 and 0.1kg organic bismuth catalyst are joined in 60kg DMF, after stirring, add 45kg HMDI, be warming up to React at 95°C for 2 hours;

[0046] (2) Add an organic solvent with 75% of the total mass of the organic solvent to the reaction solution of step (1), drop the temperature of the reactor to 40-45° C., add the diamine HMDA dropwise, and continuously add the remaining amount of solvent in the process, Add 2kg of reaction terminator MEA until the viscosity reaches 60-80Pa·s / 25℃;

[0047] (3) The temperature of the reaction solution in step (2) was raised to 80° C. and stirred for 1.5 hours to obtain a polyurethane resin.

Embodiment 2

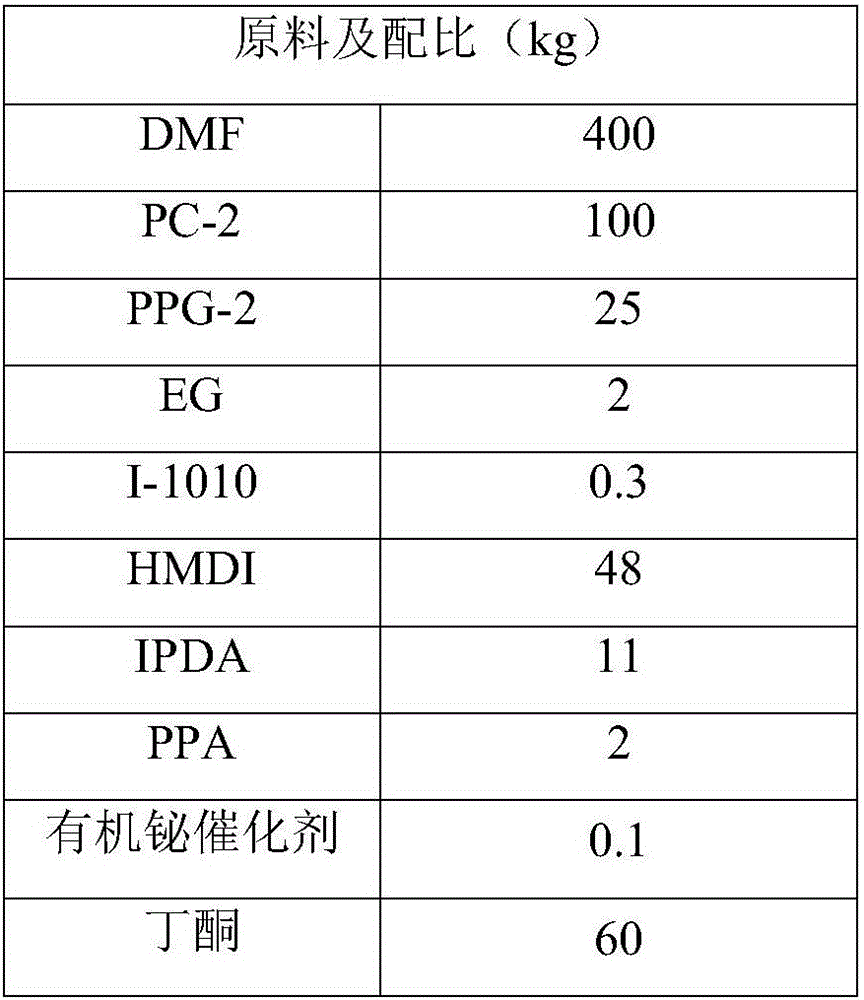

[0049] 1. Raw material and ratio:

[0050]

[0051] 2. Preparation

[0052] (1) earlier the PC-2 of 100kg, the PPG-2 of 25kg, the EG of 2kg, 0.3kg antioxidant I-1010 and 0.1kg organic bismuth catalyst are joined in 48kg DMF, after stirring, add 48kg HMDI, be warming up to React at 95°C for 2 hours;

[0053] (2) Add an organic solvent with 70% of the total mass of the organic solvent to the reaction solution in step (1), drop the temperature of the reactor to 35-40° C., add diamine IPDA dropwise, and continuously add a surplus of solvent in the process, Add 2kg of reaction terminator PPA until the viscosity reaches 80-120Pa·s / 25℃;

[0054] (3) The temperature of the reaction solution in step (2) was raised to 75° C. and stirred for 1 hour to obtain a polyurethane resin.

Embodiment 3

[0056] 1. Raw material and ratio:

[0057]

[0058]

[0059] 2. Preparation

[0060] (1) earlier the PC-1 of 80kg, the BG of the PTMG-2 of 55kg, 3kg, 0.3kg antioxidant I-1010 and 0.2kg organic bismuth catalyst are joined in 108kg DMF, after stirring, add 100kg HMDI, be warming up to React at 45-50°C for 1 hour;

[0061] (2) Add an organic solvent with a total mass of 75% of the organic solvent to the reaction solution in step (1), lower the temperature of the reactor to 40-45° C., add diamine HMDA dropwise, and continuously add the remaining solvent in the process until the viscosity is reached. After reaching 60~80Pa·s / 25℃, add 3kg of reaction terminator MEA;

[0062] (3) The temperature of the reaction solution in step (2) was raised to 85° C., and stirred for 1 hour to obtain a polyurethane resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com