Coloring system for ceramic raw material

A coloring system and ceramic raw material technology, applied in the field of ceramic machinery and equipment, can solve the problems of waste of basic raw materials and electrical resources, long equipment, labor and water consumption, etc., to achieve precise ingredients and solve the effect of heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

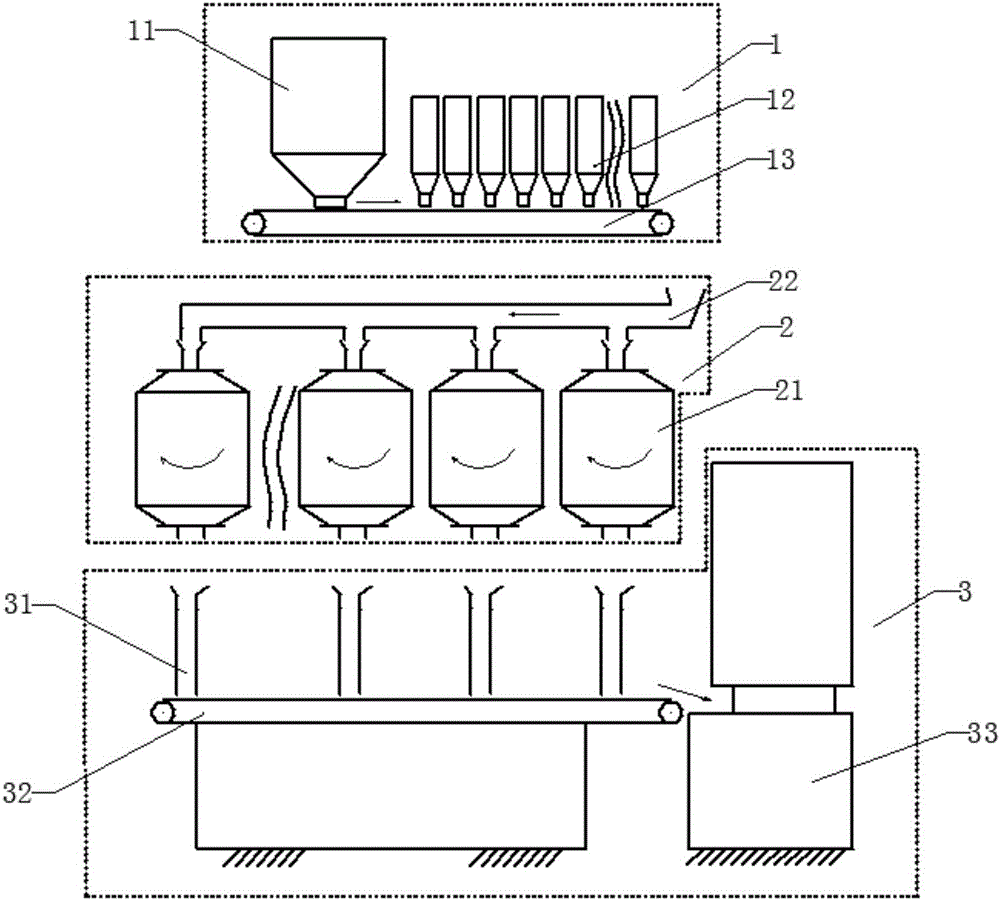

[0012] The present invention as figure 1 As shown, a ceramic raw material coloring system includes a batching module 1, a mixing module 2 and a molding module 3, wherein the batching module 1, the mixing module 2 and the molding module 3 are arranged vertically with each other, Wherein: the batching module 1 includes a basic material tank 11 and several groups of color material feeding devices 12, and an upper conveying device 13 is provided below the basic material tank 11 and several groups of color material feeding devices 12; the mixing module 2 includes several groups of stirring The device 21 is provided with a split conveying device 22 above several groups of stirring devices 21; the forming module 3 includes several storage hoppers 31, a lower conveying device 32 and a press 33, and each storage hopper 31 is arranged on a lower conveying device 32 above.

[0013] The number of the above-mentioned mixing modules (2) is 1-4; the number of the above-mentioned forming mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com