Plastic bottle conveying clamping finger mechanism and operating method thereof

A working method and technology for plastic bottles, which are applied in bottle filling, liquid bottling, packaging and other directions, can solve the problems of high manufacturing cost, difficult hardening treatment, and high cost, and achieve the effects of low cost, convenient manufacturing and processing, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

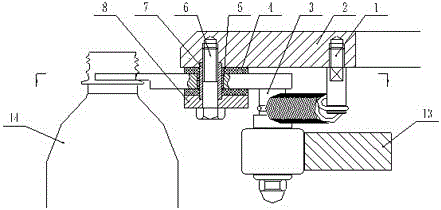

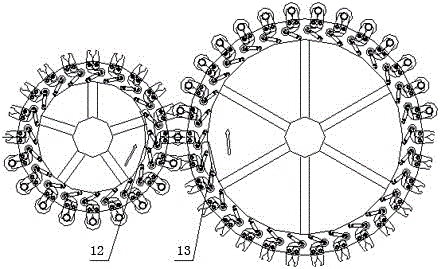

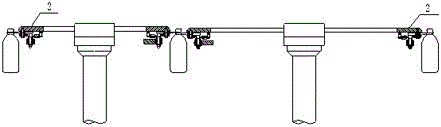

[0033] The plastic bottle conveying finger mechanism provided by the present invention is as figure 1 As shown, it includes a number of star wheel discs 2 and a number of fingers installed on the circumference of the star wheel disc 2, and each star wheel disc 2 is fixed with a number of positioning sleeves 7, and the fingers include driven fingers 9 and active The clamp finger 10, the driven clamp finger 9 and the active clamp finger 10 are connected to the positioning sleeve 7 through the sliding bearing 5 and rotate around the positioning sleeve 7, and the driven clamp finger 9 and the active clamp finger 10 are connected by a transmission pin 18; The tail end of the active clamp finger 10 is connected with a pressing roller 12 through the roller shaft 3, and the star wheel disc 2 is fixed with a tension spring hanging column 1, and a clamping tension spring 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com