Limiting switch of lifting machine

A technology of limit switch and elevator, which is applied in the direction of lifting frame, lifting device, safety device of lifting equipment, etc., can solve the problems such as the inability to meet the work requirements and the inability of the contact head to contact the conflicting parts, and achieves easy production and manufacturing. Simple and structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

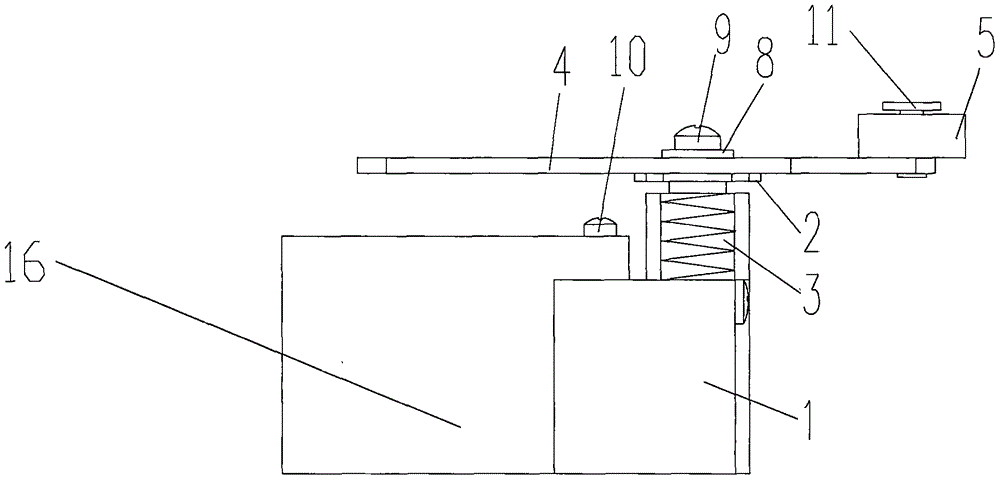

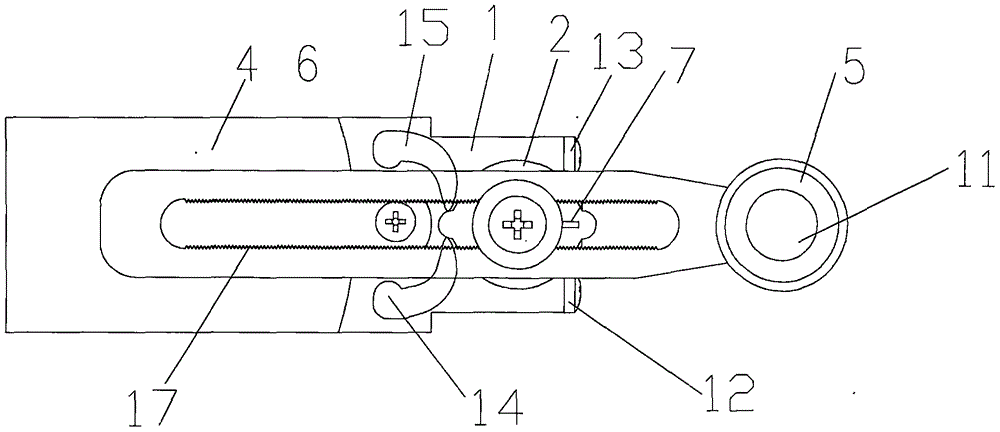

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] Such as Figure 1 to Figure 2 As shown, the limit switch of the elevator of the present invention includes a base 1, a rotating member 2, a torsion spring 3, a contact strip 4, a contact head 5, a long slot 6, a locking member 7, a gasket 8, a large cross bolt 9, Small cross bolt 10, elastic buckle 11, left limit signal lamp 12, right limit signal lamp 13, left limit slider 14, right limit slider 15, elevator boundary frame 16, anti-skid sawtooth 17, base 17 through small No. cross bolt 10 is fixed on the boundary frame 16 of the elevator. The boundary frame 16 of the elevator is located on the side of the base 1. The side of the base 1 is provided with a left limit signal lamp 12 and a right limit signal lamp 13. The upper end of the base 1 passes through the torsion spring 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com