W-type elevator guide rail connecting part

A technology for elevator guide rails and connectors, applied in elevators, transportation and packaging, etc., can solve the problems of low stiffness-to-weight ratio, difficulty in moving and installing guide rails, and achieve the effect of avoiding local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

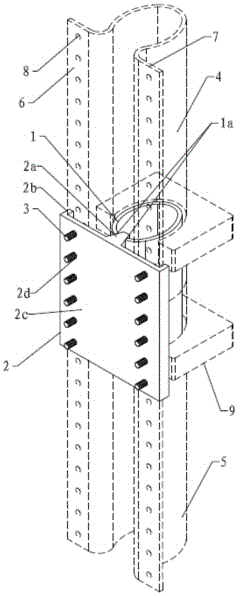

[0010] The present invention will be further described below in conjunction with the accompanying drawings: An Ω-shaped elevator guide rail connector includes a tubular connecting part (1), a base plate (2) and a fastener (3). Wherein, the substrate (2) is composed of a substrate main body (2c), a wedge (2a) and protrusions (2c) at both ends, and a fastening connection hole (2d) is provided on the main body (2c). A pair of Ω-shaped guide rails (4, 5) have a hollow cylindrical body and two flat ends (6, 7), slide the cylindrical body of the first Ω-shaped guide rail (4) into one end of the connecting part (1) until 1 / 2 of its length, then slide the cylindrical body of the second Ω-shaped guide rail (5) from the other end of the connecting part (1) until it is adjacent to the end of the first Ω-shaped guide rail (4), the base plate (2) Placed under the flat ends (6, 7) of the guide rails (4, 5), the wedges (2a) on the base plate (2) are pressed into the openings (1a) of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com