Built-in material pushing mechanism for box packing machine

A push mechanism and built-in technology, applied in the field of mechanisms that can push packaging materials, can solve problems such as being unfavorable for material packing and maintenance, increasing packaging costs and manpower and material resources, and affecting the sight of operators. Small footprint, high degree of automation, and reasonable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

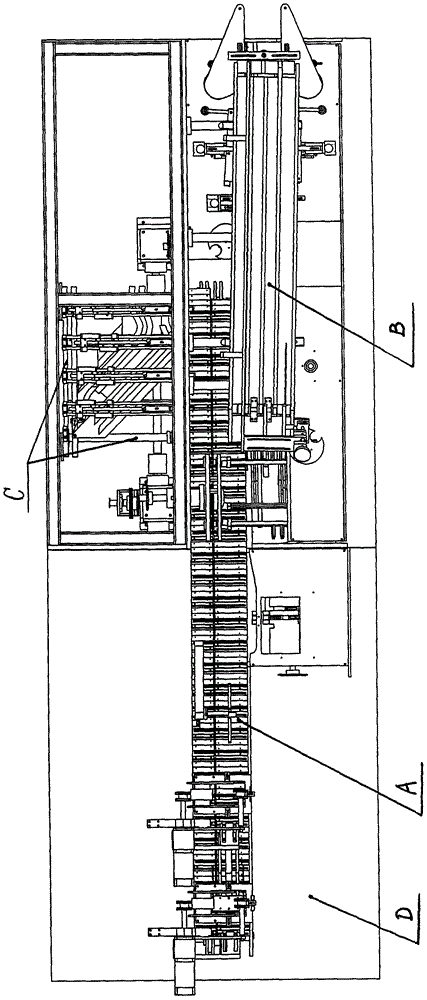

Image

Examples

Embodiment Construction

[0009] refer to figure 1 , figure 2 It can be seen that the built-in material push mechanism C of the cartoning machine of the present invention includes a pusher frame 17, a left pusher transmission assembly 18, a right pusher transmission assembly 19, and the left pusher transmission assembly 18, the right pusher transmission assembly 19 is contained in the inside (also can be referred to as built-in) of pushing material frame 17, on described pushing material frame 17, and between left pushing material transmission assembly 18 and right pushing material transmission assembly 19 places are respectively equipped with Straight track 8, first curved track 6, second curved track 13, in the straight track 8 (horizontal type), first curved track 6 (curved type), second curved track Some groups of push rods 9 are housed on the rail 13 (curved type), a push head 16 is housed on one end of the push rod 9, and a push slider 12 is housed on its other end (having upper and lower parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com