A handbrake mounting point reinforcement structure

A technology for strengthening structure and installation point, applied in the field of strengthening structure of handbrake installation point, can solve the problems of high cost, complicated structure of handbrake, heavy weight, etc., and achieve the effect of wide application range, superior ergonomic performance, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, a handbrake installation point reinforcement structure of the present invention will be further described in conjunction with specific embodiments.

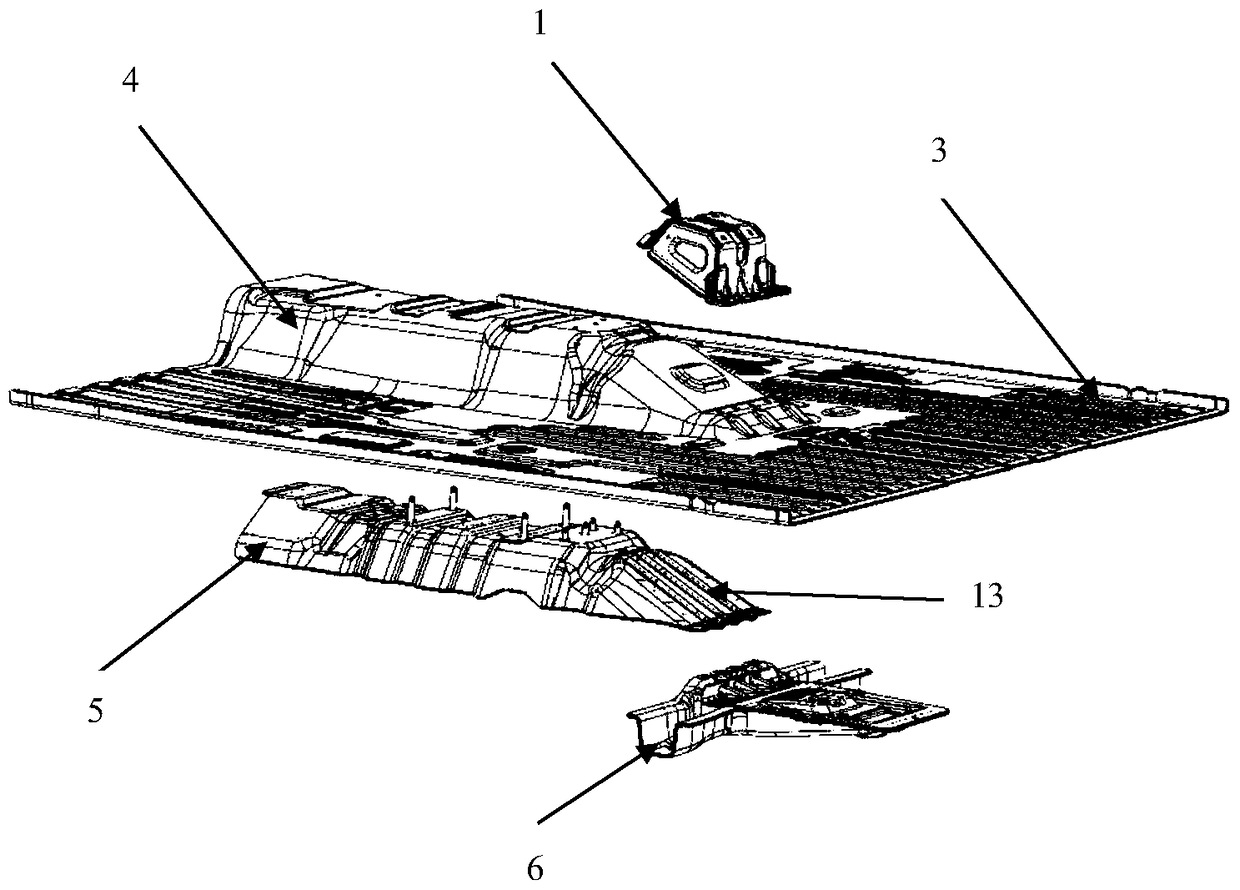

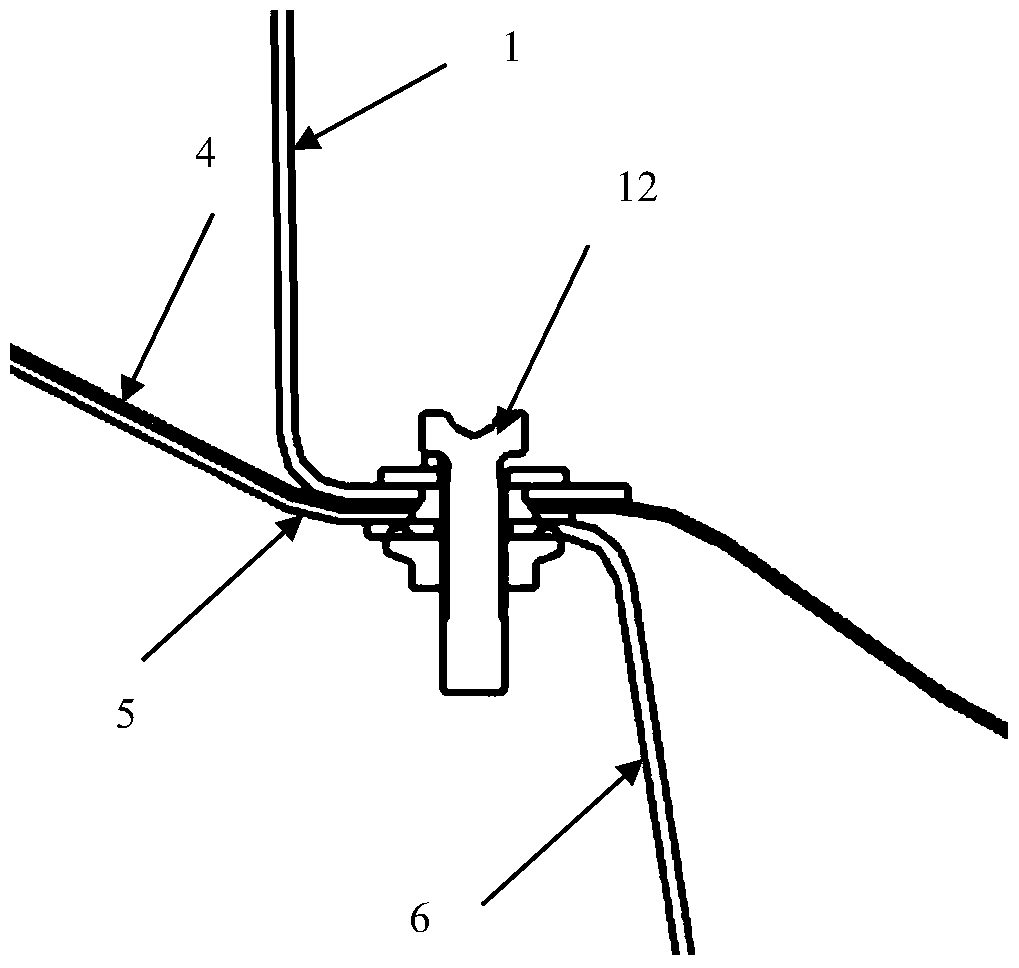

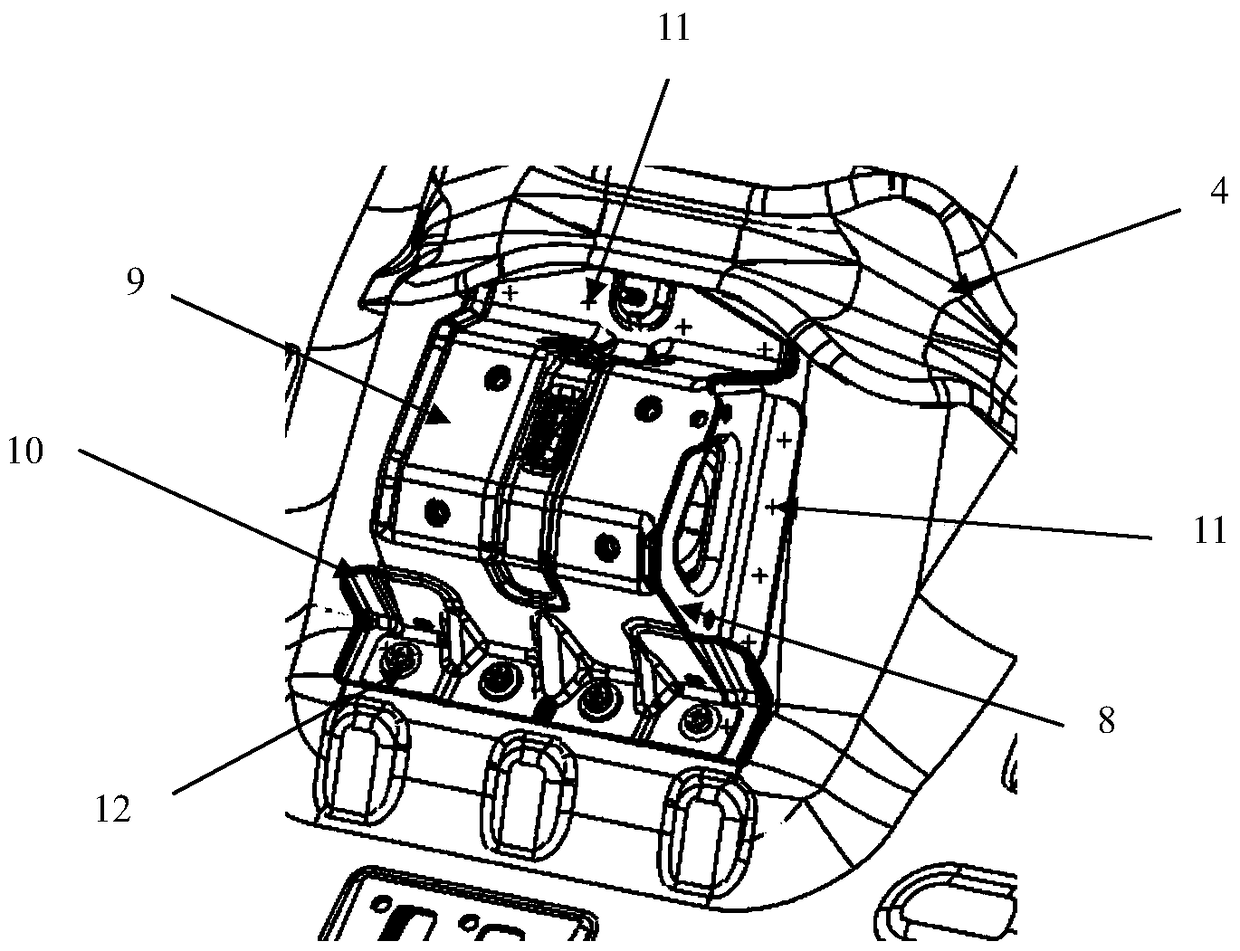

[0024] Such as Figure 1-4 As shown, a handbrake installation point reinforcement structure includes a handbrake installation box 1, a handbrake mechanism 2, and a front floor 3. The front floor 3 is provided with an upwardly convex central channel 4, and the rear of the central channel 4 is A downwardly inclined slope, the bottom of the central channel 4 is provided with a reinforcement plate 5 consistent with its shape, the bottom surface of the rear of the reinforcement plate 5 is provided with a frame cross beam 6, and the handbrake installation box 1 is arranged on the slope , The front part of the handbrake installation box 1 is fixed to the central channel 4 and the reinforcement plate 5, and the rear part of the handbrake installation box 1 is in turn connected to the central channel 4, the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com