Improved spinning bobbin transporting vehicle frame

A yarn bobbin and frame technology is applied in the field of improved textile yarn bobbin transport frame, which can solve the problems of limited number of transports, reduced textile efficiency, time-consuming and labor-consuming, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

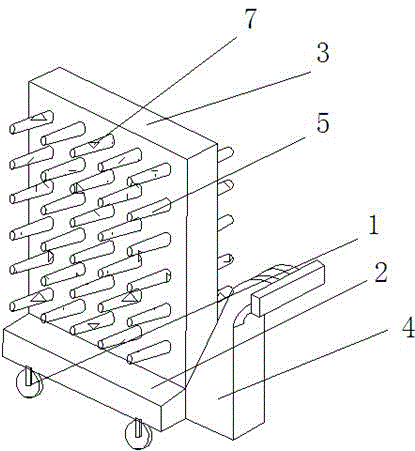

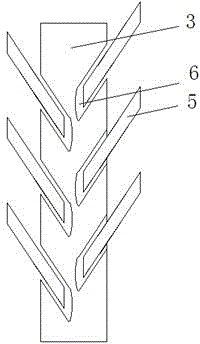

[0013] Such as figure 1 and figure 2 As shown, an improved textile bobbin transport vehicle frame of the present invention comprises a wheel 1, a vehicle floor 2, a riser 3, a push-pull rod 4 and a yarn bobbin rod 5, and the bottom of the vehicle floor 2 is provided with a wheel 1 and a vehicle floor 2 A push-pull rod 4 is arranged on the rear side of the car floor 2, and a riser 3 is vertically installed on the vehicle floor 2, and yarn bobbin rods 5 are installed on both sides of the riser 3, and the end of the yarn bobbin rod 5 is inclined upward, and a yarn bobbin is inserted in the riser 3. The insertion hole 6 and the insertion port 6 of the rod 5 are obliquely arranged inside the riser 3 .

[0014] The outer surface of the bobbin rod 5 is provided with a non-slip plastic layer 7 .

[0015] The structure is simple, and the bobbin rods 5 can be installed on both sides of the vertical plate 3. When the bobbin is transported in a short distance, it is only necessary to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com